Star Washer – What is the Difference?

In mechanical joint and fastener applications, we are using different kinds of washers. And one of these washers is the star washer application. Here we talk about the star washer applications that are generally very useful for such applications. You will learn how to select one of them and their general features.

What is Star Washer?

Star washer is an application that we use in systems where preload is very important. If we take a look at their shape of them, there are protrusions on the circumference of the washer. When you apply the fastener, these protrusions deform and create a secure connection between the workpiece and the fastener.

This deformation creates a radial force that provides extra joint force for high-stress applications.

Where Do We Use the Star Washer Systems?

In general, we use them for applications where we need to apply high preload. In systems that we need preload, we try to prevent loosening over time. And we apply excessive force to attach the fastener to the system. So, the use of the star washer applications can be very useful.

- Automotive: At the suspension systems of automotive applications, preload is very important for the healthy attachment of the star washer. Because they are dynamic systems and we require much more secure connections.

- Structural applications: Also in structural applications, the level of loads and stresses are very high at the fasteners. And we need to apply a very high preload to prevent any loosening. So, we are using these washers to add extra security to the joint.

- High-stress mechanical applications: In heavy machinery such as hydraulic and pneumatic systems, we attach the different parts of these systems to each other with star washer applications. Because we need extra security and preload in these systems.

- HVAC: In ventilation and air conditioning applications, the use of the star washer applications is very common in general.

- Electrical connections: For higher security connections, we use them for electrical connections and applications.

Selecting a Proper Star Washer for Your System

Star washers may seem like very basic parts. But it is very important to select the correct one for your application. There are different parameters that you need to consider when selecting them.

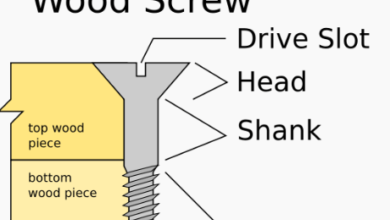

- Type and tooth location: There are different types of them that you can select. There are external and internal tooth systems that you can use for your applications. Also, you can use both external and internal toothed systems. These teeth provide the required level of lock for your application.

- Size: You need to choose washers for the screw size that you will use in your application. For example, if the size of your fastener is M6, you need to select a size that is M6.

- Material: There are different materials available and they provide different features. You need to select the correct material for the star washer application that you will use.

- Stainless steel: Stainless steel is one of the most durable and strong materials that you can use. And they are corrosion-resistant in dry environments.

- Steel: Steel material is also available with special galvanizing and coatings.

- Bronze: To prevent sparks, the use of bronze material is very common in general.

- Surface finish: On steel and bronze applications, you can different coatings and surface finishes in general.

- Zinc plated: Zinc plating provides excellent corrosion resistance in high moisture environments.

- Black oxide: Black oxide coating is very common for corrosion resistance dry environments.

- Outside diameter: The outside diameter is very important to consider. With the increasing outside diameter, the total surface area of the load increases. So, it is very important to have a bigger outside diameter to dissipate the load on the surface of the workpieces.

- Thickness: The thickness of the washer is also another important consideration that you need to make.

So it is very easy to select star washer applications for different mechanical systems.

How to Use Star Washer?

The use of the star washer application is very simple. You just need to follow these steps.

- First of all, put the star washer into the fastener that you will attach to a workpiece.

- And they put the fastener in the hole that you will attach it.

- Squeeze the fastener and apply the required amount of preload with a screwdriver or wrench.

- Be sure the wings of the star washer are folded fully. This means you applied the required amount of preload for the attachment.

What are the Prices of Star Washers?

It is very hard to give a specific amount of price. Because the prices can vary according to the material, size, and other factors. But if we need to give rough estimations about these prices;

- If you buy 1-50 pieces of them you will probably pay around $0.10-0.50 per washer.

- If you will buy 50-500 washers, you will pay around $0.05-0.30 per washer.

- And for the 500+ quantities, you will pay around $0.03-0.20 per piece.

So they are very small systems and with the increasing number of them, the general prices of these washers decrease. You need to think to buy multiple them.

Last Words

So, these are the general important points about the star washer applications. You know what applications we use and why they are useful. And also, you know the general parameters while we are buying these systems.

You can find other useful and informative articles about washers in fmechanic;

Carriage Bolt Washer – Explanation and Features

Saddle Washer – Features and Considerations

Wedge Lock Washers – Uses and Advantages

Cup Washers – Types, Advantages, and Materials

Spring Lock Washer – Differences, Types, and Materials

Hillside Washer – Explanation and Types

Threaded Washer – What Does It Do?

FAQ

The main purpose of them is to create extra security in the systems that we need to create high preloads. The protrusions create the required force on the fastener to prevent loosening.

The jagged side must be on the side of the bolt to take the performance from these applications.

Yes, they provide the performance that we expect from these systems. Because of this, people are using the in different kinds of applications.