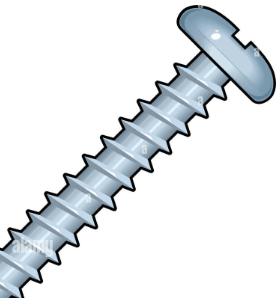

Pan Head Wood Screw Applications and Features

There are different kinds of screw applications that we can find in different sellers for the different projects and applications. One of these screw systems are the pan head wood screw. Here, we will take a look at these applications and their unique features over the other scrrew applications.

What is Pan Head Wood Screw?

As you understand that we are using the pan head wood screw applications in the wooden and carpentery applications. They are suitable for them. design of threads are best for the teh attachment to the wooden parts.

And also, pan head means, it gives idea about the design of the head. The style of head is nearly round and flattaned. So, it privides a smooth protrusion on teh wood applications.

In general, these systems are self-drilling systems. With self-drilling systems, we do not need to create a hole to apply these screws. The special edge design of these screws make if easy and possible to drill their self holes on the wood applications.

Drive Styles of the Pan Head Wood Screw Systems

You can find different type sof srive styles for the pan headd wood screw applications. They provide very different properties. But it will be much more better to select the most common one. And also, it is importan tto select according to the driver type that you need.

- Cross: This is an also the most common drive type that you can find for these applications. There are two cross lines that you need to attach a croos driver.

- Drilled Spanner: Also, this is a very rare style that you can find for them. There are two inclusion points that you need to attach your driver to these points.

- External Hex and Square: For wood screw applications, the external hex and square drive systems are generally not common. You need to use special wrenchs instead of the typical screwdriver systems.

- Frearson: This desifn is nearly same with the cross one. But the cross section is much more smaller in the Frearson.

- Hex Socket: At the top of them, there is a place that you can attach the hex socket driver.

- Phillips: In these applications, they are the most common applications. Probably nealry all the wood screw tha have pan head have thid head design. There are 4 small branches that yıu can attach your screwdriver easily.

- Slotted: This is an aslo very common screw head system for the pan head wood screw applications. They provide one of the best applications.

- Torx: Star screw design is also very common in the pan head wood screw applications.

Materials of the Pan Head Wood Screw Systems

Also there are different materials and coatings on these applications in general.

- Stainless Steel: Stainless steel is one of the most common application that we are using for the pan head wood screw systems. They provide very good structural strength and they are resistant to high corrosive environment applications. The most common tyoes, 18-8 stainless steel and 316 steel.

- Brass: Brass is an also very common material in these applications. Because of their color, they are generally suitable fo rthe wood applications indoor. So, their use is very common for furnitures. They are also verycorrosion resistant.

- Carbon Steel: This is ordinary steel that provide good strength to the system. But in carbon steel, there is no use of Chromium content for teh stainless application like the stainless steel.

- Galvanized Steel: Galvanized steel are generally zinc plated steel that is very common in the ğan head wood screw applications. If you will use these systems in outdoor applications, it is very important to choose the galvanized steel.

- Black-Oxide Coating: This is another coating that we are applying to these applications. Black oxide proives very good corrosion resistance in the dry environments. So, tehya re very useful in different systems.

Conclusion

These are the general points that we can state about the pan head wood screw applications. The manufacturers are generally provide catalogues that you can select the material, coating and drive type according to the applications that you will use.

If you have additional comments and questions about this topic, please leave them below!

Also, you can find other useful anf isngihtful articles about other screw types in fmechanic.com!

Rebar Dowels – Uses, Standards and Sizes

Star Bolt Head – Features and Uses

Jack Bolt Applications – Uses and Advantages