Welding Coveralls – Different Models

In welding operations, we are using different kinds of both for safety and comfort. One of these pieces of equipment is the welding coveralls. Here you can find the best welding coveralls that you can use for different kinds of applications.

7 Best Welding Coveralls

In terms of occupational health and safety applications, their use of them is very important. They will protect the operator from the high temperatures of the welding and slag. Check the different models of welding coveralls that you can find on the internet.

Flame Resistant FR Coverall

Flame Resistant Welding Coverall

- High-quality material.

- 88% cotton and 12% nylon.

- Different sizes are available.

This one is one of the most common ones that you can find on Amazon.com.

- A special blend of fabric that includes 88% of cotton and 12% of nylon material.

- The fabric is compliant with ASTM F1506 and NFPA 2112 standardization. And also it is UL certified.

- There are different breast and hip pockets that make it very easy to use. And also you will use the zips that are the highest in quality.

- Different sizes are available n different colors.

Carhartt Men’s Big & Tall Flame Resistant

Welding Coveralls

- 100% cotton material.

- Relaxed fit for better comfort.

- 7-day try.

This is another high-quality flam-resistant application. The seller provides 7 days of try and a money-back warranty.

- The fabric is 100% cotton which will provide the best application.

- High-quality zippers provide the safest use.

- You can wash these applications in the machine.

- NFPA 2112 compliant.

- HRC2 UL certified that you can use in occupational health and safety applications.

Leather Welding Coveralls

Leather Welding Coveralls

- Heat resistant.

- Heavy duty applications.

- Durable leather materials.

This one is also leather material that will provide the best safety for the welding operators.

- The use of leather applications in welding arm coveralls is very common. And this one is the body coverall that you can use for different kinds of applications.

- The apron will cover the body which will prevent any dangers that come from the welding operation.

- The sewing is made from high-quality US kevlar threads that are durable to high temperatures.

- Also, you can use the tool pockets to place the welding electrodes and other important welding parts.

- It is applicable to different kinds of high-temperature applications.

Flame Resistant Economy Coveralls

Lapco FR Welding Coveralls

- 100% cotton material.

- Moisture and heat-resistant.

- HRC 2 and NFPA-compliant material.

If you are looking for 100% cotton and HRC 2 and NFPA-compliant ones that are economical, this one is for you.

- The 100% cotton provides the best protection and very high comfort for welding operations.

- Different colors are available.

- Two patch-style pockets provide very good versatility to welding operators.

- The zippered front makes it very easy to fit on different bodies.

Bulwark FR Welding Coveralls

Bulwark FR Welding Coveralls

- 100% cotton material.

- Made in the US.

- Zipper closure.

This high-quality welding coverall that is manufactured by Bulwark FR is one of the best ones in others. Also, they are UL certified and NFPA complied.

- The 100% cotton fabric provides the best comfort and safety.

- CAT2 fire protection.

MAGID 1840-S Spark Guard

MAGID Welding Coveralls

- 100% cotton.

- Spark guard flame resistant.

- High-quality application.

This one is another high-quality flame-resistant welding coverall that you can find at a lower price on Amazon.com.

- The flame-resistant application is best for different systems.

- 100% cotton fabric provides very good protection against corrosion.

ATERET Flame Resistant Welding Coveralls

Flame Resistant Welding Coveralls

- 100% cotton.

- Washable in the machine.

This coverall has CAT/HRC 2, ATPV 8 cal/cm2 (electric arc flash rating), and UL NFPA 2112-2018 certifications that you can use for different kinds of occupational safety applications.

- With useful zippers, it is very easy to use in general.

- You can use it in both dry and wet conditions.

- Lightweight application.

How to Select a One?

The first important point about welding coveralls, you need to look for the standards and specifications that these coveralls meet. In the workplace where you are working, you need to know the occupational safety specifications and standards to get the correct safety equipment. You need to check the specifications and occupational safety standards that the welding coveralls cover.

Also, the body sizes must be appropriate to the worker or operator must be comfortable, and must not prevent the welding application that you are making.

And also, the material is important. In general, you can find leather and cotton welding coveralls in general. Which one is appropriate is up to you.

And prices change according to the different brands. The price depends on you. Because the different welding coveralls provide standardization at different prices.

Conclusion

These are the general points that we can state about the welding coveralls. If you have additional comments and questions about this topic, please leave them below.

Also, you can find other useful articles about welding on fmechanic.com!

Carbon Fiber Welding Hood – Prices, Advantages, and Review

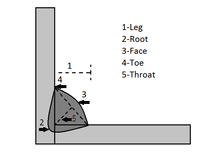

What is Weld Toe? Definition and Importance

Parts of a Weld – Both Fillet and Groove Welding