What is Weld Toe? Definition and Importance

Welding is a very important application in engineering. We are using welding systems in different kinds of manufacturing and joining processes. And there are different kinds of terminology that we are using for welding applications. One of these terms is the weld toe. Here we explain what is their importance.

What is Weld Toe?

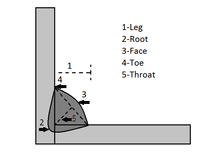

In a typical welding application, the weld toe is the starting point of the interface between the welding fill and the welded material. It has a very important place in welding operations. But we need to make the difference between them in the groove weld and the fillet weld applications.

Groove Weld

Groove weld is a welding type where we are connecting thin parts by filling them with welding material. So, it is very easy to apply welding application in these systems. The shape of the welded zone is V shape. This provides a much better connection between the parts instead of the vertical faces.

And the application o the welding filler material to the V interface is much easier. We are applying the welding operation with multiple passes on each other. The last pass provides the welding face. And the junction point between the face and the material is called the toe.

The toe must be smooth enough to prevent any disintegration. The better the welding the harder to understand where the weld toe starts.

Fillet Weld

This is also another type of welding that we are applying for the T joints. We apply the welding to the junction section of the T joints in general. The logic of them is also the same as the groove weld. There are multiple passes that we apply to the fillet junction. And the starting of the interface between the material and the filler is the weld toe in fillet weld.

Also, we expect a smooth weld toe from the fillet weld applications in general. The higher the quality of the fillet weld, the higher the smoothness of them.

Last Words on Weld Toe

The logic of the weld toe in two different types of welding applications is very simple. If you have additional questions about this topic, please leave them below!

You can find much more similar topics about welding on Fmechanic.com!