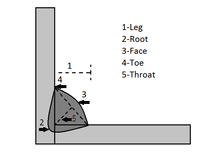

Toe Clamp Guide – Types, Uses and Selection

We are using clamp applications in woodworking and machining operations. Clamping the workpieces in the proper position is very important to apply the cutter machine or tool. So, we are using different construction of clamp systems. Toe clamp applications are one of these systems. Here, we will take a look at the general structure of the toe clamp applications and their types and uses.

What is Toe Clamp?

Toe clamp is a system in which we clamp the material with the help of a hex screw or other kinds of screws that we are attaching to the slotted section of them. And the toe section fixes the workpieces to the table. And you can easily apply different kinds of processes to these workpieces.

They are very easy and compact systems. And they do not take up lots of space to prevent the working conditions. So, you can easily use the toe clamp applications in different kinds of systems.

They provide holding applications from only one side of the workpiece. So, it is very easy to apply these systems.

Types of Toe Clamp Applications

There are different kinds of constructions of these applications. You can consider these types of applications for the application that you have.

Straight Toe Clamps

They are the most common application. It has a very straight structure that has a slot that you can adjust it. The toe section holds the workpiece, and the other edge rests on a wedge. From the middle side, you are adjusting the screw or bolt to apply the clamping on the workpiece.

Also, the wedge structures can change. They have different kinds of structures that we are applying. One of them is normal rectangular wedges that we place the edge of the toe clamp on them.

Another important structure of wedges, is they have a stepped structure you do not need to change the wedges according to the changing height pf the work pieces. You just need to change the step of the workpiece.

Self-Supporting Systems

Self-supporting systems are also very useful systems that we use for different kinds of applications. On these applications, there are no kinds of wedge systems. The trail of the toe clamp makes it possible to support the toe clamp application. So, they are very easy to use. And these systems are generally very basic.

Threaded Wedge Toe Clamp Systems

At the wedge section, there is a threaded hole to that we are attaching a screw to adjust the height of the wedge for these applications. Also, this one is very useful for the height adjustment of the toe clamp application according to the workpiece.

Block Wedge Systems

For bigger workpieces with very high clamping forces, we are generally using blocks as a wedge. They provide much better structural stability to the system. But changing the block in each machining application can be burdensome for the operator.

Low-Profile Systems

For these toe clamp applications, the difference comes from the toe design. Toe has a finger design that makes it possible to use much more little wedges.

Toe Clamps for Angled Workpieces

If the workpiece does not have regular straight faces, the use of the toe clamp applications for angled workpieces is very useful. At the toe edge, there is a pivoting ball that rotates according to the curve of the workpiece. So the attachment of these workpieces is much more simple.

Fingertip Types

In these types, there is a fingerlike toe that has minimal contact with the workpiece. They are very good for the small parts and parts that have lots of notches and other surface characteristics.

Slider Toe Clamp Systems

They are very good for surface machining operations. They are sliding on a rail to attach the workpieces for machining operations.

Selecting a Proper System

Actually, with the information above, you can select the best one for your application. According to the workpiece type that you are dealing with the selection of a proper system is very important.

The general difference comes from the toe and the wedge system application. You need to select the toe of the toe clamp application according to the material and the style of the workpieces that you are using in general.

And also, you need to choose the type of wedge according to the sizes of the workpieces. You can select the changing size of wedges if the sizes and thicknesses of the workpieces changes.

Furthermore, in the market, you can find toe clamp kits that include different kinds of toe clamps and different kinds of wedge applications. They are very useful and profitable if you are dealing with lots of kinds of different workpieces in your workshop.

Conclusion

Toe clamp applications may see very basic systems. But they are very important systems for different kinds of machining and woodworking applications.

If you have additional comments and questions about this topic, please leave them below.

Also, you can find other useful and informative articles and posts about the machining operations on fmechanic.com!