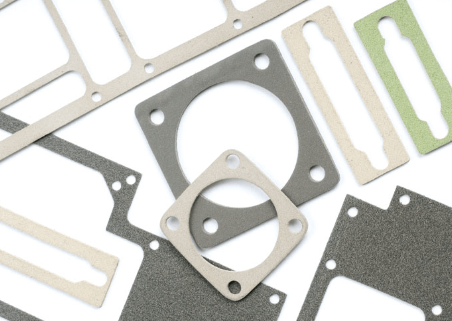

Silicone Gasket – Complete Guide, Types, Applications

Gaskets are very important applications or mechanical systems. They prevent liquid leaks. So, choosing and using the right application is a very important thing to do. Also, silicone gasket applications are very common systems that we use. Here you can find detailed information about silicone gasket applications.

What is Silicone Gasket?

A Silicon gasket is a gasket or sealing equipment made from silicone material. This material is very common in the gasket industry because of different reasons.

In history, the use of asbestos gasket applications was very common. They have excellent material properties that make them useful for such applications. But because of the health hazard properties of the silicone gasket applications, we do not use them according to the different regulations. So, silicone material become more and more common in the industry.

Advantages of Silicone Gasket Applications

There are different kinds of advantages of silicone material as a gasket system. Because of these advantages, they are very common in the gasket industry.

Wide Temperature Range

The available temperature range is a very important property of this material. The temperature of the gasket application is a very important thing to consider in general. It is one of the most important considerations. Because the gasket application must show the same performance in every temperature range that the system works.

So, silicone materials can withstand up to 400-500 degrees Fahrenheit temperatures which makes them a very common material in the gasket industry. Also, low-temperature resistance is a very important property to consider in general. They can withstand up to -100 degrees Fahrenheit temperature which makes them very useful for such cryogenic applications.

We need to point out that, the material is not only available in this temperature range. The material shows the same sealing performance in these temperature ranges.

Durability

We use different kinds of gasket applications in different external conditions. These external conditions may change according to the application. For example, some applications expose UV light which can cause the deterioration of the gasket material. Also, corrosive environments such as acidic liquids and sea water can have very bad effects on gasket applications.

So, the silicone material can withstand all of these bad conditions and extreme weather conditions. You can use them in outdoor applications and heavy-duty applications without any problem.

FDA Approved

After the new regulations about gasket materials, silicone gasket applications become more and more popular in general. Because this material is completely FDA-approved. This makes this material not harmful to human health. And it makes it possible to use in different kinds of applications such as food and medical industries.

Excellent Work in Compression

In general, it is expected that the gasket materials must work in certain pressure conditions in general. For high-pressure applications, we need to use materials that are durable enough. So, it is very important to use a system that has very good pressure resistance.

The silicone gasket applications are very good in high-pressure applications in general. They are suitable for high-compression systems such as flanges for high-pressure liquid transfer pipes.

They will return to their original shape after very high compression stresses.

Flame Retardance

In general polymer-based applications are highly flammable systems. In fire-protection applications, the use of these high-flammability systems is not a good idea in general. So, it is very important to consider low-flammability systems.

Silicone gasket applications have very low flammability rates from the tests carried out by the test institutions such as Underwriters Laboratories. So, their use is generally common in commercial applications that have flame danger.

Water Repellence

In outdoor applications or some indoor applications, external water or moisture can be a problematic issue that prevents the ideal working of the process. The use of water-repellent materials is very common in these systems.

Also, silicone gasket applications are very common in water-repellent systems that provide the best applications in general.

Electrical Insulation

You probably already know that polymer-based materials are generally resistant to electric current. And they are very important in electrical applications in general. So silicon material is a very common material in electrical insulation systems.

If you need electrically insulating applications, silicone gasket applications are very common systems in general.

Applications We Use Silicone Gaskets

Because of these very important features that we explained above, the use of silicone gasket applications is very common in such systems.

- Food industry: As we stated above, FDA-approved systems must be used in the food industry. And the silicone gasket applications are FDA-approved systems that are very common in food production systems.

- Aerospace: Because of the high-pressure resistance and high-temperature resistance, the use of these applications is very common in different aerospace systems.

- Engines: In internal combustion engines, you can find different silicone materials that are used as gasket material.

- Medical: Also in medical systems, the use of this material for gasket applications is very common. The FDA-compliant systems must be used in this area also.

- Industry: Silicone is a very good material that can withstand very extreme conditions. So, the use of silicone applications is very common in heavy-duty industrial processes.

- Energy: Also in energy sectors, the facilities that process the fossil fuels such as natural gas and oil, the use of silicone gasket applications is very common in general. Because they can withstand outdoor conditions very well without any problem.

- Telecommunication: As we stated above, the flame and moisture retardant applications make silicone material very common in telecommunication systems in general.

So, if you are looking for a proper gasket application for these areas, you can consider silicone gasket materials without any hesitation.

Types of Silicone Gaskets

Silicone gaskets are not generally in one shape or one feature. There are different kinds of applications that are used in different sectors and systems. And choosing the proper application is very important.

FDA Gaskets

As we stated above, these silicone gasket applications are very common in the food industry. They are generally FDA-certified, odorless, tasteless, and fungi-resistant systems. In the food processing systems in the food industry, the use of FDA-approved silicone gasket applications is very common.

Conductive Applications

In some electronic equipment, the use of electrically conductive gasket applications is very important. Originally, silicone gasket applications are non-conductive materials. But, with the addition of conductive materials inside the structure of silicone, they manufacture electrically conductive gaskets.

Sponge Silicone Gaskets

Sponge silicone gaskets are generally common in the cushioning and padding applications of the systems. They provide a very good compression rate that makes it possible to apply high-fitting compressions.

In general, they have two types. The open-cell sponge silicone gaskets allow water and chemical can go through the body of the gasket. But the closed-cell sponge gaskets do not allow the passage of liquids and chemicals in general.

Foam Silicone Gasket

They are similar to sponge gaskets. But the firmness can be adjusted to a required level. This is the difference between the foam silicone gasket applications. Also, they have open-cell and closed-cell applications in general.

Solid Gaskets

Solid gaskets are generally harder than foam and sponge gaskets. They have generally higher sealing capacity for higher pressure systems. The rigid structure allows only the %5-25 of total compression rates.

Die Cut Gaskets

This is the most common silicone gasket application that you can find in the market. They are manufactured in a die-cutting process. And they are generally sold in packages.

Also, they are the cheapest applications that you can find on the market.

Molded Gaskets

You can give the specific shape of gasket orders to the manufacturers of the molded gaskets in general. They are very easy-to-apply systems that you use for different kinds of applications.

So, as you see above there is a wide range of silicone gasket types are available in the market.

Parameters to Consider to Choose a Silicone Gasket System

As you see above, there are different types of silicone gasket applications that we can use in different kinds of systems and applications. So, there are important considerations and parameters that you need to assess to choose the best application for your system.

- Temperature: What is the maximum and minimum temperature that the gasket system will be exposed to in your system? You need to choose a proper silicone gasket application that must withstand this temperature range.

- Chemical compatibility: In general gaskets are very good to resist chemical attacks. But it is very important to choose the correct application if you are looking for a specific chemical resistance or chemical affinity.

- Hardness: As you see in the types, different applications have different hardness values. If the silicone gasket application is hard, you should know that the pressure of the system increases.

- Pressure: Yes, you need to know the maximum and minimum pressure range of your system. And you need to know if the gasket application can withstand these pressure values.

- Size: Also the size of the gasket is very important. Make the geometrical requirements clear and choose the correct size and shape of the gasket application.

- Compression set: The compression set of the silicone gasket means, the percentage of the maximum squeeze of the silicone gasket application in general. With the increasing compression set, the maximum squeezing percentage that the silicone gasket application shows the same performance increases.

- Application: Choose the correct type of gasket as we stated above according to the application. For example, FDA-approved systems are very important in general.

- Cost: Also the cost of the silicone gasket application is very important. You need to take different offers from different manufacturers and suppliers. And you need to make better assessments.

So, it is very easy to choose the best application for yourself.

Rubber vs. Silicon Gaskets

Rubber is generally manufactured from natural sources that make it environmentally friendly. And because of this, most companies are choosing rubber applications for these systems.

But when it comes to the temperature resistance of the rubber system, the silicone gasket application is much better in terms of the temperature resistance.

Also in terms of chemical attacks, outdoor conditions, weathering, water, and fire resistance, the silicone gaskets show much better performance.

But when it comes to the price, the standard rubber gasket applications become cheaper and cheaper. If your application is not a complex system, you do not need to choose an expensive solution. In most cases, you can choose rubber gaskets.

Conclusion

These are the general things that we can state about silicone gasket applications. They may seem very simple systems but there are different kinds of applications and types available. To choose the correct system, we prepared a basic guide to choose the best one.

If you have any questions or comments about this topic, please leave them below. Your precious feedbacks are very important to us.

Check the related topics about gaskets;

Viton Gasket – Advantages and Features

Oil Cooler Gaskets – Common Malfunctions and Solutions

Oil Cooler Gasket – Common Problems and Symptoms

Drain Plug Gasket – Replacement and Costs

Oil Filter Housing Gasket – What is That?