Turning Vanes in HVAC Applications

In HVAC applicaitons of buildings, we are using different kinds of applications such as turning vanes. They can be very basic systems but they provide very big advantages in fluid flow applications. Here you can find different kinds of information about the turning vane applications.

What are the Turning Vanes?

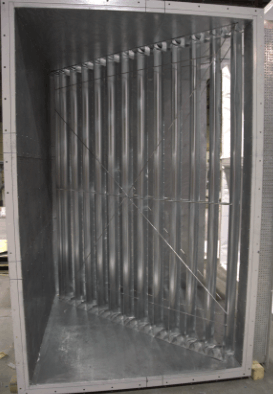

In the HVAC systems of the buildings, we are using duct applicaitons and duct works. We generally transfer the air through these systems. And there are different turning and direction changes which are generally 90 degrees. In these turning places, the fluid generally loses flow energy. Because the flowing fluid first bumps into the wall and goes in the other direction.

So, we use the turning vanes to eliminate this energy loss during the flow. The design of these systems at 90 degrees of turn provides very smooth turning to the fluid flow. And the flowing fluid does not lose its energy while it is turning.

Also, these turning vanes make flowing fluid lose energy. But this energy loss is very low if we compare it with the situation where there are no turning vanes.

You can easily understand that there are turning vanes are used in a ductwork system from the drill screws at the sides of the turning systems. So, you can be sure that these systems are very high in efficiency.

We use some pumping and compressor energy to transfer the air through the ductwork applications. And if there will be turbulence and pressure loss, we need much higher energy consumption. So we need to consider using these turning vane applications if we want to decrease the total energy consumption.

Designing Duct Works with Turning Vanes

If you are building very long duct work applications that there are lots of turns, you need to use turning vanes in general. In general, you can consider an extra $15 for each turning of the flowing fluid, if y ou uses a turning vane application. So, you need to make the calculation if the long-term energy saving will meet the expense. For the systems that have high pressure and temperature applicaitons, the use of the turbine vanes will meet this expense.

But if you are building a short system that has 1 or 2 turnings, you can consider not using turning vanes in general. Because the energy difference will not be very high to use these systems.

Conclusion

This is the general information that we can give about the turning vanes that we use in ductwork applications. If you have additional comments and questions about this topic, please leave them below.

And also, you can find other kinds of useful articles and posts about duct work and HVAC at fmechanic.com!

Cryogenic Gloves – Best Products to Consider!

Stainless Steel Coil Tubing Applications

Rectangular Duct Applications – Advantages and Uses