Stainless Steel Unistrut Applications

In industrial applications and material handling in different kinds of sectors, we are using stainless steel unistrut applications in general. They are very useful systems that we can use for different applications. Here you can find detailed information about these systems.

What is Stainless Steel Unistrut?

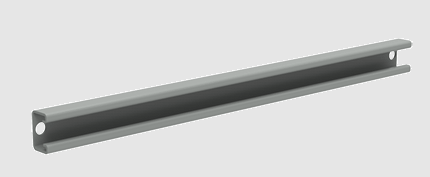

Stainless steel unistrut is a system that we are using in factories and other kinds of industrial bases for structural support for material handling systems such as pipes and tubes and others. So, while you are selecting a system, you need to know about the general points about them to get to know about them.

Types

There are different kinds of types that you can find in the market.

- Standard: The standard types of stainless steel unistrut applications are the most common ones. They have a hollow section where you can place long tubes and pipes inside them. So it is possible to create a strut system easily. And also there are openings at the bottom side of these parts to make it possible to connect pipes and tubes with clamps.

- Low Profile: These systems are generally the same as the standard system. But they have a low section of side walls that you can apply for different kinds of applications. The lower walls are better for the smaller pipes and tubes.

- Stacked: Two normal stainless steel unistrut applications are combined with each other. So, there are two lines of one unistrut application.

You can find these applications in a slotted and solid way. The slotted applications make it easy for the clamp attachments. And also you can use solid applications for direct material and fluid handling between the systems.

Important Parameters to Consider While Selecting

When you are selecting a stainless steel unistrut application, you need to consider these points in general.

- Height: This is the first design consideration for stainless steel unistrut applications. They are veyr good for your application. The total height of this application is very important for the material or pipe system that you will attach to them.

- Lebntg: This is also a very important design consideration. How much length that you need to use in your system?

- Channel Width: This is also a very important design parameter. You need to define the maximum channel width according to the material or tube and pipe application that you will use. And inside channel width is also a very important curled section that these systems have.

- Slot Dimensions: If the strut system that you selected has a slotted design, you need to define the minimum requirements of the slot designs.

- Material Thickness: According o the level of structural support, you need to define the maximum material thickness for the stainless steel unistrut application. So, they are very important for different kinds of applications.

- Material: In general as you understand from its name, there are two types of them are available.

- Steel: The difference between steel the stainless steel, the steel material does not include chrome content inside it. So, they are more susceptible to corrosion and rust.

- Stainless steel: We recommend you use the stainless steel application. They are generally higher in price but have a longer life.

- Finish Type: The surface finish that you can find for the stainless steel unistrut application that you have.

- Zinc Plated: Zinc plating provides good corrosion resistance in wet environments. They show better performance than powder-coated steel.

- Powder Coated: To prevent corrosion and rust, you can consider this one.

- Galvanized: In wet environments galvanized steels how much better corrosion resistance if we compare it with the previous ones.

Conclusion on Stainless Steel Unistrut

In the food industry, dry room applications, and other kinds of systems, the use of stainless steel unistrut applications are very common in general. So, they are very important systems that you can use for different kinds of applications.

If you have additional comments and questions about these structural elements, please leave them below.

Furthermore, if you are looking for much more content about structural systems like this one, you can check fmechanic.com for more!

Diamond Dowels – Uses in Construction and Advantages

Cable Tightener – Different Constructions

Track Roller Applications – Different Types and Considerations