Spiral Torsion Spring – Guide and Selection

We use the spring applicaitons in different kinds of systems. They are generally very useful for such mechanical systems. There are different kinds of spring applications are available. One of these types is the spiral torsion spring application. Here, you can find detailed information about them and you will learn how to select the best applications.

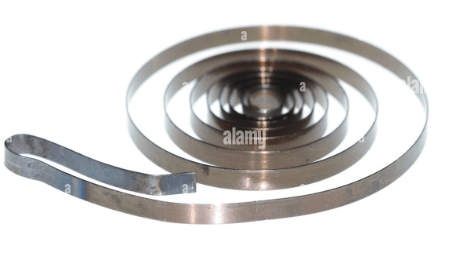

What is Spiral Torsion Spring?

A spiral torsion spring is a type of spring in which we can apply torsional force to squeeze and release applications. So they are very useful for the torsional torque and force applications such as clockwork mechanisms and mechanisms that have rotational applications.

There are different kinds of applications that we use in industry, automotive and electric motors.

Important Parameters of Spiral Torsion Spring Applicaitons

While you are choosing spiral torsion spring applications for different designs and systems, you need to consider these kinds of points in general.

- Sizes: The sizes of these systems are very important for such applications. These are the general considerations about their sizes;

- Outer diameter: At the released phase, the outside diameter of the spring. It is important because you will design a place where you will put it.

- Arbor diameter: This is the inside diameter of the inside coil. The system that you attach will define this value.

- Width: Sprial torsion spring applications are generally made from metal strips that are coiled. So, it is very important to apply it accordingly. The width of the spring is very useful for different kinds of applications.

- Thickness: The thickness of the spring strip defines the force and stiffness directly. With the increasing thickness, the stiffness of the spiral torsion springs increases.

- Load Capacity: Also, it is a very important parameter that which level of load you are expecting from these springs. It will be defined according to the mechanism that you will use these applications.

- Extended Length: The maximum length that you will use is the spiral torsion spring applications.

- Number of Turns: Total number of coils. With an increasing number of turns, the total turbine capacity and the energy storage of the spring increase.

- Shaft Diameter: Probably you will attach these spiral spring applicaitons to a shaft. So, if you know the exact diameter of the shaft it will be much easier to select the correct spring application.

- Maximum Torque: According to the physical requirements of your system, the maximum torque is also a very important parameter. You can choose different kinds of spiral spring applications that have different torque values.

- Life: How many life cycles you are expecting from a spring? This value generally changes according to the applied load and duration of application. But some sellers and manufacturers provide information about the life of applications.

- Material: Different types of materials are available but most of the high carbon steels.

Types of Spiral Torsion Spring Applications

According to the application and its features, there are different types of spiral spring systems available in the market in general.

- Constant Force Springs: They are the class of spiral torsion spring applications that provide content force wherever you squeeze or extract them. For applications that need constant pulling or pushing force to the torsional loads, they are very useful.

- Variable Force Springs: With the increasing retracting application, the force of the spring increases. So, they are very useful for the applications that you expect accelerated pushing and pulling.

- Rotor Springs: Rotor applicaitons such as drill presses, the use of them are very common. Once the rotor springs are loaded, they provide very good rotational energy to the spring application.

Conclusion

These are the general points that we can state about the spiral torsion spring applications that you are applying for. So, they are very useful systems for different kinds of mechanisms. You will be able to select the best one from the different catalogs of the firms.

If you have additional comments and questions about this topic, please leave them below. And also, you can find other kinds of useful articles about springs and other machine elements on fmechanic.com!

Spring Hook Systems – Types and Applications

Heavy Duty Spring Applications – Uses and Types

Spring Lock Washer – Differences, Types, and Materials