Pipe Beveler Machines – Guide for Pipe Welding

In various kinds of welding operations, we are using different kinds of welding machines. They are very important systems to obtain successful welding operations. Here, we will talk about the pipe beveler applications. You can find information abotu their types, how to use them, and general considerations.

What is Pipe Beveler?

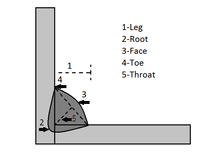

A pipe beveler is a system that creates the beveled sections at the edges of the pipes. These bevels provide the angle to apply the welding operations between the pipes. We are filling the groove that we created with a pipe beveler machine with a filler material in the welding operations. So, the welding operations become much higher in strength. And it is very important to create beveled sections in pipe welding operations.

Also, it is very important to create beveled sections in welding operations. So, every time we need to use pipe beveler machines we can apply for different applications.

What are the Types of Pipe Beveler?

There are different types of pipe beveler machines are available in the market. According to your requirements and needs, you can select the best one for your applications.

- Handheld pipe bevelers: They are the systems that operators can carry with them to the job site. And they have a power system with an electric motor or hand crank. We need manual power for the hand crank application.

- Bench-mounted pipe bevelers: They are stationary systems that we can create bevels on bigger and thicker pipe applications. We mount these systems on benches and generally, we can not carry these systems with us. And in general, they are powered by gasoline or electric engines.

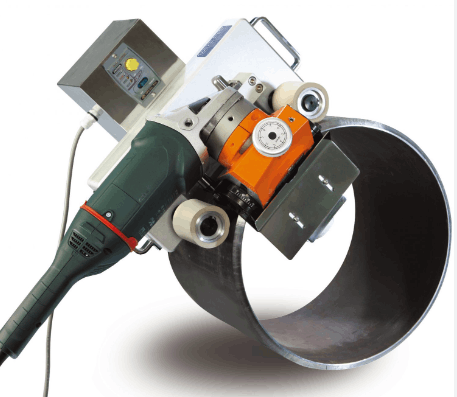

- Automatic pipe bevelers: They are automated beveler machines to create bevels on different sizes and materials of pipes with a computer program. They are generally the best applications to create consistent and successful bevels.

- Pipe end-facing machines: The main purpose of these machines is not to create bevel sections. They are generally designed to create a square or flat end. But we can use them to create bevels on the ends of the pipes.

- Pipe-cutting beveling machines: They provide highly accurate beveled sections in pipe welding operations. Also, we can use these machines to cut the pipes.

How to Use a Pipe Beveler?

There are important things that you need to consider while you are using a pipe beveler machine.

- First of all, you need to comply with the occupational and safety for the workplace that you are working in. Wear protective glasses, cut and heat-resistant gloves, and your welding coverall.

- After that, adjust the settings on the pipe beveler machine according to the manufacturer’s instructions. Be sure you attached the proper beveler tools.

- Turn on the beveler machine and allow it to come to the top speed. Top speed is the important thing to cut the bevels appropriately.

- While you are applying the beveling, be sure that you are creating the pipe bevel with the required accuracy and precisionç.

- When the operation is completed, be sure that you stopped the machine fully. And check the beveled section.

- If there are additional operations are required at the beveled section, make sure to apply the general touches with your hand to correct these sections.

- Do not forget to make the maintenance of the pipe beveler that you are using.

How to Select a Pipe Beveler?

If you are thinking about buying a pipe beveler, you need to make different considerations like the one below. And you will be able to buy a proper system with this guide.

- Maximum cutting diameter: In pipe welding operations, we deal with different kinds of diameters of pipes. And we need to create beveled sections for these pipes. And be sure that the pipe beveler can bevel the biggest diameter pipe that you will weld.

- Maximum thickness: What is the maximum thickness of the pipe beveler that you are using can be cut? Different machines have different cutting depths. Make sure that the system that you are buying can cut the maximum thickness that you are dealing with.

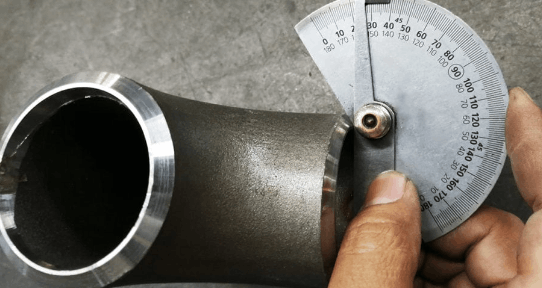

- Cutting angle: The general applications can cut the bevel angles between 0-45 degrees. And the most used bevel angle in pipe welding operations is 37.5 degrees. So, be sure that you are using pipe beveler systems that are useful for different kinds of systems.

- Flexibility: Also be sure that you can use these systems for different diameters, different materials, and different thicknesses of pipes. Probably you want a system that provides a wide application that you can use for pipe bevelşimng.

- Speed: The speed of the pipe beveler application is generally measured with mm/s or inches/second. And you will have a project to make at a specific time. So, be sure that the speed of the pipe beveler is sufficient for the welding applications that you are using in general.

- Durability: Will this application will provide the same performance for a while as the first day? To be sure abotu this, you need to look for the general user comments on the buying page of the pipe beveler application. So, it is very important to consider the warranty that they are providing to the users.

Last Words

So, beveling machines are very common in the pipe welding industry. And there are different types of them are available. Even there are systems that are using oxy-acetylene cutting. With this guide, you will be able to select the best application for your system.

We gave all the important parameters that you need to consider abotu the pipe leveler systems. And selectşng will be much easier.

Please leave your comments and questions about these systems below.

And also, you can find other useful topics about welding here;

Pipe Jack Stand – Complete Guide for Selecting the Best

Pipe Chain Clamps – What is It?

Welding Coveralls – Different Models

Welding Arm Pad Applications – Different Types and Styles

Carbon Fiber Welding Hood – Advantages and Review

FAQ

The main purpose of the pipe beveler application is to create bevel angles at the pipe welding connections.

The bevel is the important connection section between the different pipes. The angle provides a groove that you can fill with the filler material for the welding. So, it is very easy to design bevels in piping applications.

The angle is 37.5 degrees in general. It is a standard application in pipe welding applications.