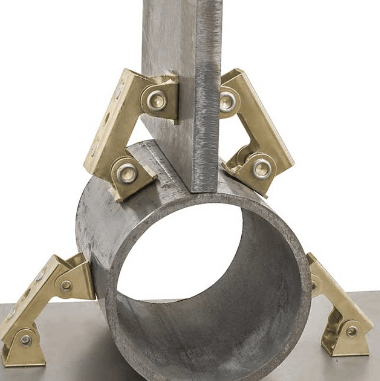

Magnetic Clamps – Types and Applications

In woodworking, metalworking, and welding operations, we are using different types of clamp systems. One of these systems is the magnetic clamps. Here, we will take a look at the general features of magnetic clamps and their types.

What are the Magnetic Clamps?

Magnetic clamps are the systems in which we are attaching the ferrous and magnetic workpieces to apply different processes to them. They are very useful systems because we can efficiently clamp the different workpieces.

Types of Magnetic Clamps

There are different types of magnetic clamps that we are using in different kinds of applications.

- On/Off Clamps: They are the clamps that we can easily one and off with a switch. There are multiple magnetic systems to that we can attach different workpieces at one time. So, switching them on and off is very easy for these applications.

- Classic Types: They are the clamp applications that magnetically attach the workpieces on these systems. And to remove the workpiece, we need to use a special lever.

- Adjustable Angle Clamps: They are the special clamps that the angle of the magnetic system can be adjusted. Unlike the other systems that have specific angle values, the adjustment of the angle provides very good versatility for different kinds of workpieces.

- Miniature Clamps: They are smaller applications that we can use several of them to hold different kinds of workpieces easily. So, they are very useful systems. Hoşdign angles generally change between 0 to 180 degrees.

- Outside Magnetic Clamps: From the outside of the workğpieces, they can hold them magnetically.

- Three-Axis Clamps: Are these applications that we can use for the three-axis clamping applications? You can use several workpieces in the same clamp.

Important Points to Select Magnetic Clamps

There are important points and parameters to select that we are using in manufacturing applications.

- Maximum Magnetic Pull: This is the most important parameter while you are selecting an application. They directly define the strength of holding force for your workpiece. Different magnetic clamps are available between 50 lbs to 1500 lbs of magnetic force.s

- Holding Angle: In general, the different types of them are made according to the holding angle values. According to the type of workpiece that you are dealing with, you need to define the angle at that you want to hold the application. Also, adjustable angle systems are very useful applications.

- Geometric Dimensions: According to the type and shapes of the workpieces that you are using, it is very important to have geometric dimensions. So, you can find different kinds of sizes.

Conclusion

Magnetic clamps are very basic and very useful systems that you can find different kinds of applications of them. And you can select the best one with this guide from the manufacturers. If you have additional comments and questions about them, please leave them below.

Also, you can find other kinds of useful articles and blogs about clamping systems and manufacturing systems on fmechanic.com!

What is Weld Toe? Definition and Importance

Square Copper Tubing Systems – Manufacturing and Applications

Free Machining Steel – Uses and Advantages