Eccentric Reducer Complete Guide – Materials and Installation

In piping and plumbing applications, we are using different kinds of elbows and other kinds of pipe applications. One of these applications is the eccentric reducer systems that we are using. Here we talk about eccentric reducer applications. You will learn how to install them, the differences from the concentric ones, the materials, and more.

What is an Eccentric Reducer?

An eccentric reducer is a system that we use in piping and plumbing applications. As you understand from the name they are reducing the flowing fluid diameter. If there is a difference between the connecting pipes, we are using reducers between them. And they make it possible to flow fluid between the different-sized pipes.

Why We Call It “Eccentric”?

This is because the centerlines of the connecting pipes are not at the same level or orientation. And one side of the reducer is flat, and another side is inclined. And also there are concentric reducer applications available in the market.

Concentric reducer applications are also systems in that we apply concentric applications between the pipes.

What are the Differences between Concentric and Eccentric Reducer Systems?

They may seem very basic constrictions but there is an important difference between the eccentric and concentric ones.

In general, we are using the concentric reducer applications on the discharge side of the pumps. They provide a very good discharge of the liquid from the pump. And we use the eccentric reducer applications at the pump inlets.

Also, another reason that we use the eccentric reducer applications, they are very useful for systems where the pipes must be at the same level. Think about a system that we need to lay the pipes on a specific surface. So, we lay the flat side of the eccentric connection to create a system that we can easily lay on the ground or surfaceç

Another difference is, eccentric reducer systems are generally better to prevent air trapping inside the pipe system. When we install the flat side bottom, they prevent the bubble trapping that can cause cavitations in the pump şnlets.

These are the general differences between the eccentric and concentric reducer applications.

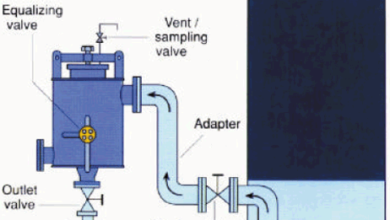

How to Install an Eccentric Reducer?

There are different ways to install these applications according to the installment types.

- Butt weld: If the eccentric reducer application is made from metal or steel, the use of the welding operation is very common. The operator must keep clean the welding section and he needs to create a uniform weld at the connection. Generally, the welding provides the best sealing in the pipe connections.

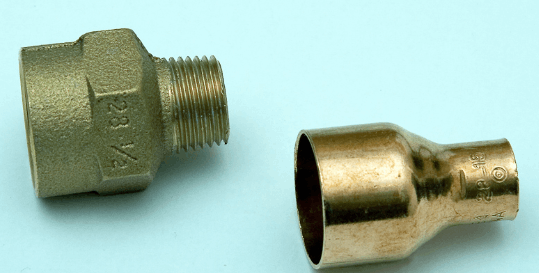

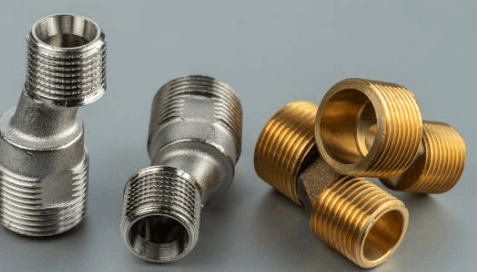

- Threaded connections: Threaded connections are generally very common in piping and plumbing applications. The most important advantage of plumbing systems, they provide a detachable system. So, they are very useful for these applications.

- Socket connect: Socket systems are also very common in the eccentric reducer application. They are one of the most common and easy-to-install systems.

- Clamped applications: We create the connections between the pipes and the eccentric reducer applications with clamps.

Materials

There are also different materials for these applications available. These materials provide the best application according to the external and internal flowing conditions.

- Steel: Steel and stainless steel provide very good mechanical strength for applications where there are lots of physical effects from the environment. And if there are coatings are used such as galvanizing, they are also very good in corrosion resistance.

- Plastic: In plumbing applications, the use of PVC reducer systems is very common. Because they provide very good sealing and very in terms of the corrosion.

Other Important Parameters to Consider

Also, there are other important parameters that you need to consider about the eccentric reducer applications. While you are selecting an eccentric reducer system, it will be very useful to consider these points about them.

- Size: Size is a very important parameter that you need to consider Define the inlet and outlet sizes of the pipes. But these inlet and outlet sizes are generally made according to the inlet diameters.

- Pipe material: Considering the correct system for the pipe material that you are selecting is a very important thing. So, you need to choose the best application according to the system that you are using. In general, selecting a material that is the same as the pipe material is the best selection.

- Liquid type: From acetic acid to water, the purpose of the use of the eccentric reducer can change. And the corrosive behavior of the fluid can change according to an application. So, it is very important to select a proper material for the type of fluid that goes inside. For example, you need to select plastic solutions for acidic liquids.

- Length: To which length you can do this reducing application? The length is a very important thing that you need to consider. If you use too short a length, the abruğt reduction of the fluid can cause cavitations and other unintended problems may cause. And also if the pipe is very long, it can be a problematic issue in terms of placement.

- Wall thickness: After defining the inlet and outlet diameters, you need to select a proper wall thickness for the reducer application that you have.

- Pressure range: The fluid will flow inside the reducer in a specific pressure or pressure range. So, you need to know the available pressure range for the reducer application that you are using.

- Temperature: In which temperature that the eccentric reducer application will serve? You need o select a system that can serve minimum and maximum temperatures that it will be exposed to the liquid and the environment.

- Specifications: If you are selecting a part for critical or industrial applications, it is very important to find the systems that comply with the specifications of the industry that you are working in such as ASTM, ASME, UL, etc.

Also, you need to know that when you use an eccentric reducer application in a system, the pressure and the velocity of the fluid will change. So, you need to make calculations by using Bernoulli’s equations if there are any problems with the changing pressure and temperature values. And also, you need to be sure about if there will be any cavitations on the inlet of the pump. You can be sure about it by making cavitation calculations.

Last Words

So, this is the general information that we can give about eccentric reducer applications. They may be very basic systems but there are lots of points that you need to consider.

We explained the important points about installation and their general differences from the concentric applications. And also, you know the important parameters that you need to consider about these systems. And it will be very easy for you to select the best eccentric reducer application.

If you have any questions or comments about this topic, please leave them below. Your precious feedbacks are very important to us!

Check the related topics about plumbing and piping;

Why You Should Start to Use Bidet Nozzle?

40 Gal Pressure Tank – Will It Be Sufficient?

Steam Fittings – What are They? Considerations

Threaded Tube – Selection Guide

Swedge Fitting Applications – Uses and Features

FAQ About Eccentric Reducer

The purpose of the eccentric reducer applications is to reduce the diameter of the pipe that fluid flows inside it. They connect the larger-diameter pipes to narrower diameters.

In eccentric rescuer, the centerlines of the connection pipes are at the same direction and level. But in the eccentric applications, the centerlines of the concentric pipes are not on the same level.

In general, there are different application areas of the eccentric and concentric systems. We use the eccentric systems at the inlet side of the pumps that are aligned horizıontally. Eccentric systems provide better cavitation and bubble formation prevention than concentric systems. But in vertical fluid flow applications, concentric systems are generally better.