Drain Valve – What is It? Important Things to Know

Different kinds of valve systems and applications are very important in the different kinds of systems. One of these applications is the drain valve system. Here you can find detailed information about the drain valve systems that are available in different engineering systems.

What is Drain Valve?

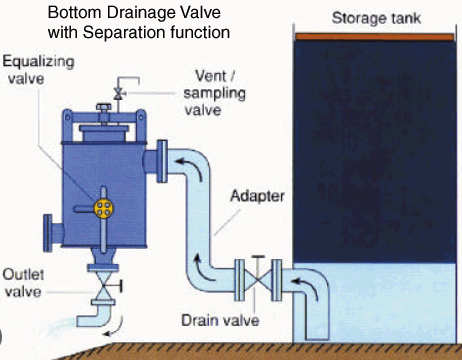

As you understand from its name, drain valves are used to drain liquids, gases, and other substances from compartments and tanks. They are generally located at the lowest point of the tank. You just need to open the drain valve and discharge the liquid from it.

Applications We Use Drain Valve

The use of drain valve applications is very common.

- Plumbing: In the plumbing and piping systems, drain valve applications are located at the lowest point of the system to make it possible to drain all the water.

- HVAC: Also in the HVAC systems, draining the condensed water or coolants from the system can be very important in such situations. So, we use the drain valves again.

- Compressor systems: Also they are used to drain the compressed gas and air systems. In such situations, we need to drain the gas or compressed air from the tank system from the drain valve.

- Marine: Also the use of drain valves is very common in different kinds of marine applications.

- Automotive: In oil pans and radiators, we use drain valves in general.

So, they are generally useful in the maintenance and repair applications of such systems that include different kinds of fluid inside them.

Types of Drain Valves

In general, the general valve types can be used as drain valve applications. According to the different systems, the use of drain valve systems is very common.

- Ball valves: Ball valves are the most common application that we use as a drain valve. In HVAC applications and plumbing systems, they are generally very useful. They provide very good performance for high-flow rate applications.

- Globe valves: There is a globe system in which you can accurately adjust the fluid flow. In HVAC systems, the use of these applications is very common.

- Gate valves: There is a gate-shaped butterfly that prevents or allows the fluid flow inside the different kinds of systems. Their use is generally common in industrial applications.

- Butterfly valves: You know the butterfly valve in automotive applications. They are a very basic system that has an opening and closing butterfly-shaped plate that rotates around its axis. Their use is generally common in large-diameter pipeline applications.

- Check valves: Also, check valves are very common in plumbing and HVAC applications. They only allow fluid flow in one direction. And prevents fluid flow from another side. So, they provide a very secure system for you.

- Diaphragm valves: There is a plastic or rubber diaphragm that seals the valve body to prevent fluid flow. They are generally common in chemical processes. Because the rubber material can withstand chemical reactions.

Important Considerations While Selecting a Drain Valve

There are different kinds of other parameters that you need to consider about drain valve applications. If you make the considerations well, it will be very easy for you to select the best application.

- Flow rate: Flow rate is generally dependent on the size of the container and the volume of the material that needed to be drained. You need to make flow rate calculations and drainage time calculations to select the best size.

- Fluid type: Fluid type has a profound effect on the different kinds of applications. Because some fluids can be very corrosive and very hard for specific materials. So, in this case, choosing a plastic application will be much better.

- Pressure: You need to know the maximum pressure on which you will operate the drain valve in your system. What is the maximum pressure that you will use? And you need to choose the drain valve application according to this maximum pressure.

- Temperature: Like pressure, the maximum temperature is a very important thing to consider. You need to analyze the maximum pressure rating that the valve must withstand in general.

- Price: Take different offers and quotes from the different valve brands, manufacturers, and suppliers. It will be much easier for you to choose the best application for yourself.

What are the Symptoms of a Bad Drain Valve?

Also, you need to make the maintenance of the drain valve. Because these systems are responsible for the safety of the running application. These are the general symptoms in general;

- Leakage: The leakage may take place because of the worn and torn sealing and the valve parts. So, you need to change the seals or the leaking parts with a new one. Or, you can directly change the valve itself.

- Drainage problems: Also there can be filth and debris that prevents the effective drainage of the fluid from the system. So, you need to clean the system properly.

- Stiffness: If turning the vane the valve is hard, the possible reason for it is the worn system. Also, corrosion or rust can be the main reason for this. In this case, you need to remove the rust or change the worn and torn parts.

- Corrosion: Also corrosion will cause leaks. If a valve system is corroded, you need to replace it with a new one.

- Noisy: Hissing and popping sounds are the common symptoms of noisy operation. The main cause of this problem is the trapped air inside the bad valve.

So, changing and cleaning are generally the most common solutions for drain valves in general.

Conclusion

These are the general things that we can consider about drain valve applications. They are very basic applications. But you need to make different kinds of considerations in different cases.

If you have additional comments or questions about the drain valve applications, please leave them below.

Also, you can check other informative articles about drain valve applications;

Air Compressor Check Valve – Guide with All Info You Need

Capped Valve- A Useful Solution to Fluid Flow Systems

Car Seal Guide – How to Use? What Does it Mean?

Heater Control Valve – What is It? How it Works?

Idle Control Valve – Everything You Need to Know!

Exhaust Valve – Problems, Types and Solutions

SharkBite Shut Off Valve – Detailed and Unbiased Review

Pressure Washer Unloader Valve – All the Points You Need to Know