Wear Ring Systems – What is Their Purpose?

In different kinds of complex machinery, different kinds of basic parts have very important duties in these systems. Here, we will explain the wear ring systems that we are using the in the engineering applications. You can find information about the types, purposes, and applications of these systems here.

What is the Purpose of Wear Ring Parts?

In rotary and reciprocating machinery, there is a very big wear problem with the moving parts. For example, the shaft of a pump stays inside a casing. There is an allowance between the shaft and the casing to allow for the rotation of the shaft. But this allowance must not be high. Because liquid leakage problems may occur.

And also in reciprocating machines such as piston pumps and petrol engines, there is an allowance between the pistons and the casing or block. So, with the reciprocating motion of the piston, there is wear takes place. So we need to take care of this excessive wear.

The purpose of the wear ring systems appears here. We are using ring systems between the reciprocating or rotating parts and the casings or blocks of them. And with passing time, the wear ring wears because of this motion. After a while, we change them with the new one.

So, they are the parts that we are placing inside these systems to allow for the wearing. And the main casing or engine block does not wear. Only a small part wear.

In general, we use poılymer materials for the pump systems. They provide very good structural assistance and they are very good for the sealing application to prevent any leakage. Once the leakage starts, we understand that we need to change them.

And also in internal combustion engines, we use these applications to prevent wall friction and wear of the engine block. You can find these rings at the heads of the pistons. And in general, these rings are made from high-carbon wear resistant steel material.

Types of Wear Ring Parts

There are different geometries and materials of wear ring applications in general from different sellers.

Standard Pump Wear Ring

The standard applications are generally made from ye glass-filled nylon material. We can say that they are composite materials both provide good wear resistance and good sealing.

High-Speed Wear Ring Applications

The material of this class of these applications is PTFE which allows a much more slippery surface to allow for very good high-speed rotational applications.

Stock Wear Ring

Also, some of the wear ring suppliers provide stock applications. You can cut and directly change the wear rings of the different parts and pumps. If you are using the pump applications in a very common way, you can consider these types of them.

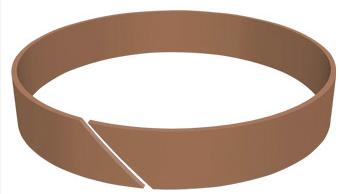

Butt Cut

The cutting application of the wear ring systems is also very important in terms of the different features. The butt cut provides a very easy installation. But their performance is generally lower if we compare it with others.

Angle Cut

Angle cut is the most common cut geometry that you can find in wear ring applications. The applications that have higher bearing stress in the gap between the rotating shaft and the casing, these systems perform best.

Step Cut

Step cut is not a common application in these applications. But they provide much higher gap stress. And if your application has a peak stress, this will be a very good geometric application.

Applications That We Use Wear Rings

Maybe you understand the general applications that we use in the wear ring systems. But it is worth to mention about them.

Piston Pumps

The use of them in piston pump systems is very common. We are attaching the wear ring application between the wall and the pistons. The stresses between the piston and wall are sinusoidal. So there are peaks and feet in the stress. So, it will be better to consider the angled cut of these systems in your applications.

Centrifugal Pumps

Centrifugal pumps have an impeller that şis attached to a shaft. The shaft rotates inside a casing that has the very good structural integrity to the pump system. The stresses are not changing in general in centrifugal pump applications. So, it is very important to have these systems.

Last Words on Wear Ring Systems

As you see above, the wear ring applications are very important applications that prevent the corrosion and wear of the main casing and the engine block.

These are the general points that we can explain about the wear ring systems. If you have additional problems and questions, leave them below!

You can also find other insightful posts about pumps and machine parts in Fmechanic!