Boilers are very important systems in most of the engineering systems that we have today. There are different kinds of boilers and heat exchangers available in the market. One of the most common types of boilers is the vertical fire tube boiler. Here, you can find detailed information about vertical fire tube boiler applications. You can find advantages, disadvantages, working principles, and applications that we are using these systems.

What is a Vertical Fire Tube Boiler?

A vertical fire tube boiler is a system the generates hot steam that the different engineering systems need. We use this superheated steam in energy generation plants, locomotives, and so on.

Sections of the Vertical Fire Tube Boiler Systems

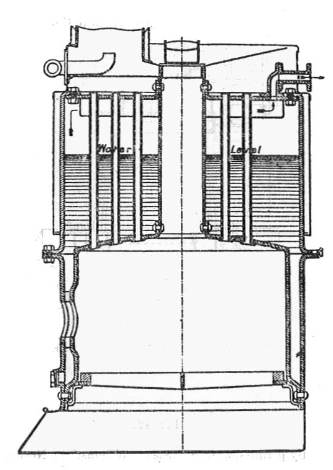

Different sections work interchangeably to produce steam. These sections are;

- Combustion chamber

- Water Chamber

- Steam storage

- Chimney

Combustion Chamber

This is the first section of the vertical fire tube boilers where the combustion of the fuel takes place. There are different kinds of fuel types are used; coal, wood natural gas, etc. So the type of burner system changes dramatically according to the type of fuel system that this system contains.

In the combustion chamber, the heat that we require to increase the temperature of the water is created. The burning efficiency is a very important parameter in the combustion chamber. Engineers are trying to design chambers that give nearly all the heat generated in the combustion chambers of the boilers.

In the combustion chamber, hot gases and fuse are created to heat the water or fluid inside the water chamber.

Water Chamber

This is the second section of the vertical fire tube boiler. This is the section where the vertical tubes are staying. Inside these vertical tubes, the hot fuses and hot gases are travelling through. And these tubes are passing through the water chamber where the water resides. With the heat transfer between the fire tubes and the water inside the water chamber, heat transfer takes place.

The temperature of the water increases and very hot steam is generated. And the steam is deposited inside the steam storage.

Steam Storage Unit

At the steam storage unit, the hot steam is deposited. The system that needs the hot steam to work such as the locomotive system, takes the required steam from this chamber. The pressure and the temperature of this storage unit are very high. And it must withstand these conditions without any accidents.

Chimney

Expelling the burnt gases is very important from the system. The chimney is a small system that expels the hot gases that we generate with the burning of the fuel inside the combustion chambers. Also, they expel the hot gas and fuse from the chimney.

The chimney system must be long enough to expel the burnt gases from far away from the system. Because the vertical boiler needs oxygen and clean air for the clean combustion inside the chamber. If the clean air that comes to the combustion chamber is mixed with the exhaust gases, the combustion will not be efficient as we expect.

Systems that We Use Vertical Fire Tube Boilers

There are different kinds of systems that we are using these vertical fire tube boilers to generate steam.

Central Heating Systems of Buildings

For large buildings that need lots of heat for the heating system, we generally use vertical fire tube boilers in general. We use the hot steam inside the heating and radiator systems of the apartments and the other systems. Also, the hot water supply comes from the central boiler systems of the apartments.

Power Plants

Power plants consist of big steam turbine systems to generate electricity. The boiler systems like those above generate hot steam. Also, vertical fire tube boiler systems are very common in the electric generation systems of power plants.

Old Locomotives

Old locomotive systems are also very common in the long-range freight systems in Russia and other Asian countries. We are using wood and coal as a fuel for these locomotive systems. There are vertical fire tube boiler systems in these locomotives that generate steam. We use hot steam to create the moving power of the locomotive.

Advantages and Disadvantages of Vertical Fire Tube Boilers

There are different kinds of advantages and disadvantages of these systems in general. If you are looking for a boiler system for an application, you need to be aware of the vertical fire tube boiler system’s advantages and disadvantages.

Advantages

- The biggest advantage is, they are highly efficient systems if we compare them with the other boşler systems. Because there is a direct heat transfer between the hot gases and the water.

- Thanks to their upright structure, they take up much lower space in the room.

- They are generally low-price systems if we compare them with the other systems.

Disadvantages

- The corrosion of the fire tubes is very high. Because transferring the hot fuse and gas directly inside the tubes makes them very prone to corroding. In general, horizontal systems are decided.

- Changing the tubes very often can be a problematic issue. It is an extra cost that you need to consider.

- If the water level is not fully inside the water chamber, a portion of the fire tubes are not heating the water directly. We refer to the fire tubes inside the water for efficient heat transfer. Because of this, adjustable horizontal systems are preferred to vertical systems.

Important Parameters of Vertical Fire Tube Boiler Systems

While selecting a vertical fire tube boiler, you need to consider these parameters;

- Working pressure: The total pressure that the steam reaches inside the steam chamber. It is important for the system that you will supply steam.

- Size and Capacity: Also you need to consider the heating capacity of the boiler. The unit is generally MBH. It means it is the thıusand BTU per hour. Generally, you will face this unit while you are looking for a boiler.

- Turndown Ratio: Turndown ratio of the boiler means, it is the ratio between the maximum and minimum operating load of them. You need to consider it according to the range of the steam generated by the boiler that you need.