Thread geometries are very common the manufacturing industry. There are different kinds of parts that have threaded systems. For example, screws and internal thread geometries are very important must o fthe machinery and daily use. Here we explain the general aspects of the thread rolling machine that we use in the tread manufacturing. You can find very insightful information about these machines.

What is Thread Rolling Machine?

Aswe stated above we use thee machinery in the thread cutting applications. In terms of the serial production o fthe different geometries, we use these machines.

If we take a look at the general working principles of them, there are threading dies that they are rotatiing around the blank. Blank is the starting part of the threaded geometries. And dies of the thread rollign machine are rotating and giving shape to the thread rolling machine in general.

In general the thread dies are made from very high strength of materials asuch as high carbon and high alloy steels. These steel materials are very hard and tough to give thread geometric shapes to the blanks.

Types of Thread Rolling Machine

There are different types of these machines according to the application of the die configurations in general.

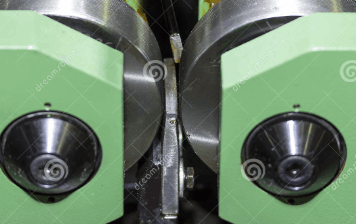

Cylindrical 2 Die Configuration

This is the first type of these machines. In this configuration, there are the cylindrical thread dies that they are rolling to each other The blank comes between these two cylindrial dies and takes the shape of the threads of two dies.

Also this configuration is one of the most common one that is generally used in the manufacturing processes.

Cylindrical 3 Die Configurations

Instead of 2 dies, there are 3 dies that the machinery comes contact with the work part or blank. They are rotating according to each other. And take the workpart between each other to obtain the threaded geometry on the blank.

In general, the production rates of the 3 die configurations are higher than the 2 die configurations. Because less time is required to obtain the part from these machines.

Cylindrical 4 Die Configurations

This is the thread rolling machine configurations that has 4 dies that they are rotating to each other. So, this is the most rapid prodyution fo threaded parts. And less time is required to obtain one complete part.

But in general, the cost of the different dies and complex machinery is an another expense that you need to consider. The motion system is much more cpmlex and there are more die that adds up extra cost to the manufacturing.

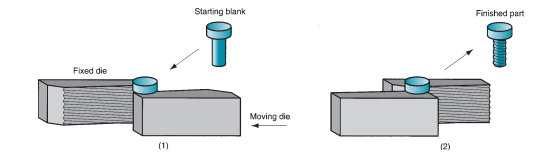

Flat Die Thread Rolling Machine

Instead of the 4 die configurations, there are two flat thread dies that the part is rolling between the 2 flat dies. So, the die configuration is much more basic than the other ones. And in one pass we can thread roll the multiple of blnaks between the thread rolling dies.

Planetary(Rotary) Thread Rolling Machine

In planetary thread rolling machine, there are two dies that cocentrically aligned. And the blanks are between these dies that they are rotating according to each other. So, rolling the parts are much more easy.

This is the most easy and most rapid production techniqee that we can produce the serial productio of teh threads.

In threaded stud manufacturing, the use ofthe planeray thread rolling machine are so common in general.

Advantages of the Thread Rolling Machines

We can manufacture the trheaded procuyst in different kinds of ways. But in the serial production manner, the use of the thread rolling machine are so common. And most of the screw manufacturers are using these machines to obtain different kinds of threaded fasteners.

Disadvantages

There are also some kinds of disadvantages of the thread rolling machine in general.

- The dies are very high in cost. Because of that we can not apply for the low quantity production. They are suitable for the high quantitiyu production rates in general.

- Lubrication is very important. Because, heat rise can be a problematic issue in the serial production of the screw threads in general.

- There are different standards and shapes of threads. And manufacure the different stadnards, you need to use different die shapes which is an extra cost.

Application Areas

Actually, the general application areas of the thread rolling machine are the application areas of the threaded fastemers and geometries. We are usign threaded fasteners nearly in all types of industries. There are different kinds of standards of the threads. And thread geometry manufacturers are manufacturing the different kinds of thread geometries with the different kinds of dies.

Last Words on Thread Rolling Machine

Also, turning operations are important alternatives to the thread rolling machine. You can easily create different kinds of shapes adn standards with the turning operations with only one cutting tool. But teh production rate will be much more lower than the thread rolling machine. If you manufacture single and unique threaded fasteners and parts, turning operations can be very good for them.

These are the general points that we can state about this topic. If you have additional questions about these topics, youc an directly ask in the comments. And also you can contact with us!