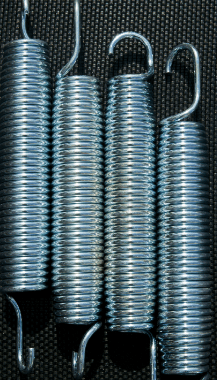

Spring Hook Systems – Types and Applications

We are using the spring systems in different kinds of machinery. So, they are very useful in general. Here, we will explain the general types of spring hook systems that we are using. And you can find information about the important parameters while you are selecting them.

What is Spring Hook?

It is a system that we are hanging items on them. They are a type of extension springs that there are hooks at both ends. And we can attach these spring hooks and hang different materials on them. According to the shape of the hook at the end of these spring hooks, there are different types of them.

- Side Spring Hook: The structure of the hook system of the side spring hooks is very simple. The hooks at the ends are located on the leftmost side of the spring coil. This provides space for the other machinery.

- No Hooks: Also on a spring hook system, there can be no hooks the user can adjust the structure of the hook according to themselves. They can use different kinds of tools to do it.

- Extended Hook Systems: Also the extended hooks are very useful if you want to hang long parts on them. Their hooks are much more extended vertically.

- Cross Over Center Hooks: The hook is made from a very long string that you can easily attach different kinds of materials and structures them. So, they are very useful in low-load systems in general.

- Machine Spring Hook: We use this hook system in heavy-duty machinery in general. They are very useful systems that provide very good structural applications. The design o hook is made for carrying heavy loads.

- Double Loop Hook: Double loop hooks are common structures to provide much more height mechanical hanging strength for lifting applications.

- Straight Wire: The straight wire extension makes it possible to adjust the shape of the hook.

- Carabiner: Instead of using spring hook systems, carabiner systems are also very common. You can attach ropes and chains without any problem.

Important Parameters to Consider About Spring Hook Systems

While you are selecting these systems, it is very important to consider these parameters. They are very important parameters that you need to consider about them.

- Length of spring hook: This is one of the most important parameters that you need to consider about this system. This is the length that you need for your application.

- Diameter: Also the diameter of them is very important. It will affect your design considerations.

- Materials: There are different kinds of materials available for spring hook systems in general.

- Carbon steel: Is a high-strength material for structural applications.

- Stainless steel: Stainless steel applications are also very common in most spring hook systems. They have Chromium content that prevents rust formation.

- Zinc-plated steel: Like galvanized steel, zinc-plated steel is very good corrosion resistance that you can use for different applications.

- Wire Diameter: The wire diameter of the coil is a very important parameter in the strength and stiffness of these systems. With the increasing wire diameter, their stiffness of them increases.

- Maximum Load: The maximum load of the system is, where the plastic deformation of the spring starts. You need to consider this one because you need to know the maximum weight that you can carry with these systems.

Conclusion

As you see above, the spring hook applications may seem like very basic systems. But they are very important systems that you need to consider different kinds of parameters about them. And while you are applying them, you need to choose the best one.

If youı have additional comments and questions about this topic, please leave them below.

Also, you can find other useful and insightful articles about springs and machine elements on fmechanic.com!