Shot Forming Processes – Applications, Advnatages and Features

Also, people call the process the shot peen forming. We are using these processes in different kinds of applications. They provide very good mechanical characteristics for such engineering systems. In here, we will talk about the shot forming processes and their features, applications, and advantages.

What is Shot Forming?

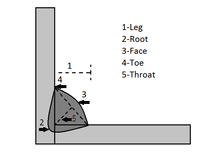

Shot forming or shot peen forming process is a type of process in which we are blasting small metal balls to the surfaces of the parts. And we create local curvatures that have local compressive effects on the surfaces. With the application of lots of small metal balls, they are very good in creating very good mechanical characteristics on the surfaces of the work parts.

We are using special machines for these applications. And these machines are generally two types.

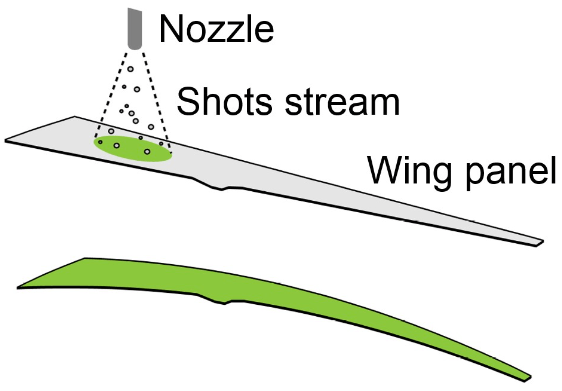

- Nozzle Systems: In these systems, there is a special nozzle that throws the sho peens on the surfaces of the workpieces. So, we obtain the effect of the shot peening application. We generally apply this process inside a cover or chamber.

- Centrifugal Wheel Machines: They are special machines that travel along a path. And on this path, the workpieces are placed. There is a rotating plate that throws shot peens on the surfaces of the workpieces. For the serial application of the shot peening applications, we use these machines in general.

In both systems, you can adjust the volume of peens and the throwing speed that you need. So according to the type and shape of the workpiece and the material of the workpiece, we obtain the best shot forming application.

Why We Apply Shot Forming on Workpieces?

There are different reasons that we apply this process to different workpieces and materials.

- The first and most important purpose of the shot forming operations, we obtain surfaces that are resistant to flexural bending fatigue and corrosion cracking from the surfaces. The extra compressive stresses prevent the occurrence of fatigue cracks and corrosion bending.

- On some workpieces, we apply the shot forming operation in a pre-loaded way or without any loading. According to the type of material, we obtain much more durable surfaces.

- We can form much thicker surfaces to withstand the external corrosive and stress effects on the different materials.

- The application of the process is very simple. We are not using any additional dies or other applications in general.

- Also, we generally apply these processes at room temperature. So the microstructure of the workpieces does not change because of the change in the shape of the surface.

Applications That We Use Shot Forming

There are different kinds of applications that we are using for the shot forming processes.

- Aerospace: In aerospace applications, the external effect of the atmosphere at very high speeds is very important on surfaces of different applications. For example at the wing surfaces, we apply the shot forming process to obtain much more high mechanical characteristics at the surface. Also at the rocket bodies, we require much better surface characteristics to withstand atmospheric situations.

- Crankshafts: We use crankshaft applications in different kinds of internal combustion engines. They are systems that undergo lots of dynamic stresses in a very short time. So, we expect better performance from them to obtain much better applications.

- Shafts: We use the shafts in power transmission between the motor and the machinery. And they can undergo stresses that have cyclic bending or cyclic axial loads. And the cracks will start from the surface of these components. With the application of shot forming processes, we create very good surface characteristics on them.

Conclusion

As you see above the shot forming applications are very important in most of systems. You can find these applications in different kinds of manufacturing sites of aerospace and power transmission.

If you have additional comments and questions about the shot forming processes, please leave them below.

FAQs

With the peen-forming processes, we create local compressive stresses on the surfaces of workpieces by throwing small metallic balls with special machines. And these compressive stresses provide much better surface characteristics to the surfaces.

The most important purpose is, we modify the mechanical characteristics of the surface of the workpieces to withstand certain loading and external conditions in service life.

The purpose of the shot blasting is to improve the surface tolerances by obtaining much more smooth surfaces. But the purpose of the shot peening, we generally obtain compressive stresses on surfaces by creating local inclusions with throwing balls.