Screw Shank – What is the Purpose of This?

We use screws in different kinds of applications such as metalworking and woodworking applications. They may seem very basic parts but they have very different features and properties that their geometry includes. One of these geometric features is the screw shank geometry. People are curious about what is the purpose of the screw shank. Here we explain what is that and what is the general purpose of it.

What is Screw Shank?

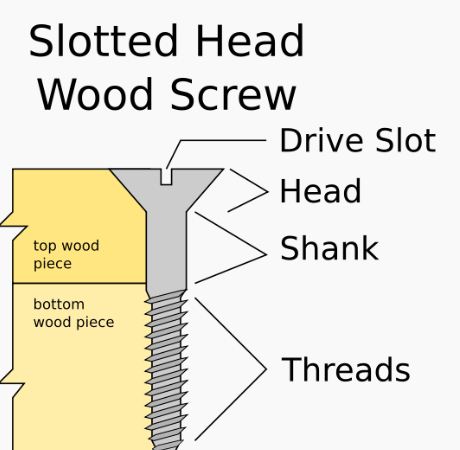

To understand what is the screw shank, we need to understand the general geometric portions of the screw geometries in general.

- Head: This is the top section of the screw. We are applying the torque to place the screw into the hole. At the top of the head, there is a blank where we put our screwdriver. And there are different kinds of designs that you can find. Also, there are different types of heads for different applications.

- Threads: Screw threads are the main geometry that we screw the thread inside the parts in general. The thread shape makes it possible to do screwing action.

- Point: This is the endpoint of the screw geometries. The tip is pointed and makes it possible to dip into the parts of the screw section.

- Screw Shank: Between the thread and the head of the screw, this is the blank portion of the screw. This is the place that we have a question about it. Why there is no thread geometry and there is a blank shank on this portion?

In general, we see this geometry for the wood screws. And not all the screws have screw shank geometry. The general reasons for it generally like this;

More Strength for Wooden Materials

The first purpose of the shank geometry, it provides much higher strength for the wooden materials. The screw geometry provides interference with the material and makes it possible to plunge inside the material. Jut just need to turn it with the screwdriver. But when it comes to the shank section, you need to apply much higher torque Because no screw thread will automatically plunge into the material. This makes a much more strong connection between the screw and the wooden material.

Screw Shank Allows Washer and Nut Attachment

Another purpose of the screw shank, they allow the washer and nut attachments in general. Because of this, we have a very strict washer and nut attachment on the screw applications in general. But applying these parts to the screwed and threaded sections is harder.

Screw Shank Prevents the Overheating Problem

While you are screwing the wooden parts, there is an overheating problem may occur in the wooden material. Because there is friction between the threads and the screws. So, it is a problematic issue for the wooden parts. When the wooden part heats, it will expand. And if the screw hole expands, the screw attachment will be looser.

But if we have a screw shank geometry for the screw attachment, the heat is dissipated from the shank section to the outside much more easy way. This will prevent overheating and problematic issues with the heating loosening.

Last Words

As you see above, the most basic geometric features on fasteners have very important duties. A basic shank geometry on wood screws makes it easy to apply different kinds of applications.

Also, you can find other informative articles about fasteners and mechanical parts. If you have additional questions about this topic, please leave your comments and questions below.

Similar Posts;