Rocker Arm – What is That? What is the Duty?

There are different kinds of automotive engine parts available in internal combustion engines. Even the most basic parts have very important duties in general. One of these applications is the rocker arm system. Here you can find detailed information about the rocker arm systems. And learn about them in detail.

What is Rocker Arm?

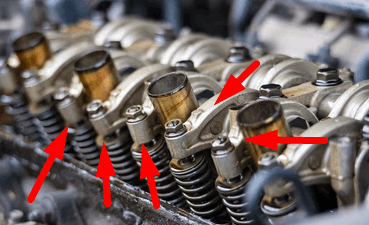

The rocker arm is a very simple engine part that makes a slight rotation over the engine cylinder head. At the first end of the rocker arm, camshaft buckles are in contact. Because of the eccentric shape of the camshaft buckles, the rocker arm makes a reciprocating movement.

At the other end of the rocker arm, there is a stick attached. This vertical stick is also attached to the engine valves. So, with the rotation of the camshaft, the rotational movement is converted to a reciprocating movement by the rocker arm. And this movement opens and closes the intake and exhaust valves at the required times.

How to Match Up the Timing of the Engine?

Yes, timing is very important for fuel burn and mechanical energy production. The intake valve must open to take the air-fuel mixture inside the cylinder. And close in the compression phase. And after the ignition, the exhaust valve must be opened.

The propulsion to rotate the camshaft to make these movements comes from the timing belt. The timing belt is attached to the crankshaft which takes the rotational movement from the cylinders. So the design of the engine must be perfect and the design of the camshaft must be perfect to obtain the required movements to work the engine without any problem.

And rocker arms are very important parts here to convert the rotation o the camshaft to the reciprocating motion of the valves.

And also there are springs on the rocker arm applications that return the rocker arms to their first position.

This is the general working principle of the rocker arm application.

What are the Alternative Systems to Rocker Arms?

Rocker arms are not the only system used in engines to operate the valves with camshafts. There are other kinds of mechanisms are available. If you know these applications, it will be much easy for you to assess the general applications.

- Overhead Camshaft(OHC): These systems are more basic systems that the camshaft is directly located on the engine head. And with the rotation of the camshaft, the valves are controlled with the help of the tappets, lifters, and followers. So, there is no need for complex applications in these systems.

- Pushrod: In general rocker arm application, the application of the pushrod systems is very common in general. But there are systems where some pushrods are located between this application and the camshaft. This system doubles the movement of the system.

- Finger Followers: There are small fingers that are touching the camshaft in eccentric places. And takes that motion and directly transfers it to the valves. They are more basic applications if

we compare with the normal rocker arm systems.

- Direct Acting Valve Train: As you understand from its name, the valves are directly acted with the camshaft lobes. There is no need for extra systems to operate the applications.

- Camless Valve Train: These are the systems in that there is no camshaft rotation or activation. There are electromechanical systems such as hydraulic or pneumatic systems that directly activate the valves.

So in different engine systems, there can be different kinds of these applications available.

Advantages of Rocker Arm Systems

There are different advantages of rocker arm applications in general if we compare them with the other systems that we explained above.

- First of all, they are basic mechanical systems that do not need additional electrical or electronşc control systems. This makes them very simple and cheaper applications in internal combustion engines.

- Low cost: As we stated above they are comparatively low-cost applications if we compare them with other systems.

- Efficient: Rocker arm applications generally multiply the movement of the camshaft and transfer the movement to the valves in a more efficient way.

- Easy to adjust: You can adjust the clearance of the valves if an engine system has a rocker arm system. This provides very good advantages for the tuners.

- Reduced wear: Also the wear on these systems is very low. Because the forces are low if we compare them with the other kinds of applications.

Disadvantages

Also, rocker arm applications have important disadvantages that make the engineers and engine designers use other kinds of systems in general.

- Problems at high speeds: In high revolutions, the forces and the acceleration can create a force on the rocker arm mechanisms that prevent the efficient valve opening and closing sequences.

- Additional parts: As you see above, other kinds of systems have much more basic applications. These systems are generally more basic systems than the rocker arm applications. Extra moving parts add extra load to the engine.

- Failure potential: Also the additional moving parts increase the potential of the failure of the rocker arm applications.

So, these are the general important advantages and disadvantages of these applications in general.

Which Common Engines have Rocker Arm Applications?

The rocker arm applications are very common in such engine systems that are being used today.

- Chevrolet 350 V8 Engines: This is the first example engine that uses the rocker arm applications.

- Briggs & Stratton Small Engines: This is another engine that uses these applications.

- Harley-Davidson Engines: We know the Harley Davidson engines are the engines that have rocker arm applications. So this is another aspect that makes them classical.

- Ford Mustang 5.0L Coyote Engines: High-performance racing engine example.

- Toyota 2JZ Engines: Supra… A classical racing car is very common in racing communities using the rocker arm applications in general.

So, one may think these applications are historical engine applications. But as you see above, the use of rocker arm systems is very common in most high-performance engines.

Which Problems May Take Place?

In general, rocker arm applications are the durable mechanical component that does not have as many problems as the other sensitive engine parts. But there are general problems that we see in these applications.

- Brakings and cracks: These applications are generally made from stamped steel that has a very durable and strong structure. But breakings and cracks may take place.

- Lubrication issues and wears: Like the other moving parts of the internal combustion engine, frequent lubrication may be required to prevent wear. Especially the contact point of them with the camshaft lobes is an important point of the general application.

- Fatigue: Fatigue can be a problem for them.

- Sticking: If the lubrication is not good and if there is wear on these parts, sticking of the valves can take place. In this case, the engine will not work properly.

- Misalignment: This is an issue that takes place because of construction problems.

If You Have Bad Rocker Arm…

If you have a bad or faulty rocker arm, these are the general symptoms that you may have in general.

- Strange noises: At low engine speeds, you can hear ticking sounds coming from the valvetrain of your engine. So, you can understand that there can be a problem with this part of your car.

- Misfires: Because the valves will not work well, misfires can happen in your engine. So, you can hear sounds coming from your engine.

- Performance: Your engine performance will drop. You can feel it when you push the gas pedal.

- Check engine light: The check engine light will on if you have a problem with your part.

Last Words

So, they may seem like very basic parts of an engine in general. But they have a very important duty at the valvetrain of your engine.

If you have additional comments and questions about the rocker arm applications, please leave them below.

Related;

Oil Filter Socket – What is It? How to Choose?

Oil Filter Housing – What is That? Complete Guide

Diesel Injector – The Most Complete Guide! Prices, Maintenance…