Metal casting is a very important business that has a very big market in the manufacturing industry. There are different kinds of metal casting and forming techniques available. Rheocasting is one of these metal shaping and casting methods. Here, we will take a look at the rheocasting operations in general. And you can see the advantages and disadvantages of the rheocasting operations. You can find the general applications of this method used in the industry.

What is Rheocasting Operation?

Rheocasting is a very different form of metal casting operations. In the rheocasting operations, the metal is not fully molten like in the other processes. And this metal slurry is applied to a mold with pressure application.

Because of this feature of the rheocasting operations, it is one of the semi-solid die-casting processes. So, there is a die that includes the metal mold. And we apply the metal slurry to fill all the spaces of the mold.

Application of Rheocasting Operation

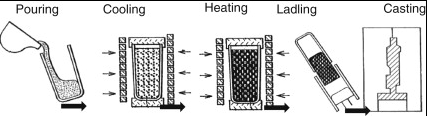

There are different steps to apply the rheocasting operations in general. These steps are generally applied to obtain a rheocasting operation.

Melting the Metal

This is the first step of these operations. In this step, the metal is melted in special furnaces. These furnaces are generally electric furnaces that we are commonly using in metal casting applications.

Obtaining the Metal Slurry

After the solidification of the metal takes place, we pour the metal melt inside a chamber where we obtain the metal slurry that we need. In this chamber, we are controlling the heat to hold the metal at a specific temperature to obtain the ideal slurry for the rheocasting operation.

Application of Slurry to Die

After this process, we apply the metal slurry at high pressures to the metal dies to take the shape of the mold. Also in general, they apply the pressure in a specific way. The pressure application systems are generally hydraulic or pneumatic. Hydrauşic systems are better at the application of the ehişgh pressures.

Also, mechanical clamping systems are very common in pressure applications. They apply the pressure up to a specific level when the metal slurry takes the whole shape of the mold cavity.

Solidification

After the metal fills all the places inside the mold cavity, the solidification of the metal takes place. After the solidification, we take the metal part from the die cavity.

These are the general steps that the rheocasting operations have.

General Applications of the Rheocasting Operations

The most common materials in these operations are aluminum and magnesium alloys in general. So they are very lightweight and low temperature to melt. Also, the most common applications are automotive applications.

Air Suspension Systems

Air suspension systems from the alumşnum alloys are a very important application of these operations in general. They are very lightweight and very good in accuracy. The serial production of the air suspension systems is very easy with rheocasting operations.

Also, the production of air suspension brackets is very common in rheocasting operations in general. This is the general reason why we are applying these operations and systems.

Aluminum Automotive Cabin Parts

The production of automotive structural parts is very common with these operations. Because they are light in weight and need to possess very good structural integrity in general. So, it is very important to have an automotive cabin part.

Defense Industry

Magnesium alloys are very common in the defense industry because of it is very lightweight applications. In aerospace applications, we manufacture magnesium alloy structural parts with rheocasting operations in general. Magnesium becomes very unstable in the molten state. So, you need to apply the rheocasting operation to a semi-molten state in general.

Advantages and Disadvantages of Rheocasting Operations

Like the other manufacturing processes, there are advantages and disadvantages of these operations in general.

Advantages

- The most important advantage of the rheocasting operations is the dimensional accuracy is better than the other casting operations. This is because we do not completely melt the metal while we are applying it inside the die cavities. So, defects like shrinkage are much lower if we compare them with the other systems.

- After the production of the parts with this method, they are generally suitable for heat treatment and other kinds of welding, and additional applications. Because the products that come from rheocasting operations are generally near-net shape.

- You do not need to apply extra processes to remove the burrs or other defects to obtain the net shape. Because this process provides near-net shape parts in general.

- Die life is much higher in the rheocasting operations. Because the application temperatures of the rheocasting operations are much lower than the molten metal processes.

- We can obtain very good dimensional accuracies and very thin sections without any problem if we compare them with the other metal casting operations.

Disadvantages

- Obtaining metal slurry for the rheocasting operations requires an extra process. So, so it means extra expenses that you need to consider. Because, to obtain the metal slurry, we melt the metal and obtain the slurry from the molten metal. This means it is an extra cost.

- Temperature control of the metal slurry must be very good. So this requires an extra cost on the equipment that you need for the rheocasting operations. But in metal casting operations, we are directly pıuring the molten metal to the die cavity in general.

So, these are the general advantages and disadvantages of these processes.

Last Words about Rheocasting

According to the information that we give about the rheocasting operations, you need to have a very complex system and apply it accordingly. But you are having much higher accuracies and better precisions from the magnesium and aluminum alloys. If you are manufacturing products for the automotive and aerospace industry which require lightweight applications, generally they are very profitable in terms of price.

So, rheocasting operations are very important operations to obtain high-quality parts from aluminum and magnesium alloys. And we are using these parts in aerospace and lightweight electric cars in general. Because of this, we can say that rheocasting is a new technology that has a future.