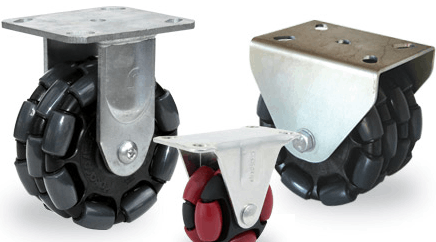

Multi Directional Caster Guide – Applications and Considerations

In industrial applications, the use of casters to move different objects between different sections is very common. Also, multi directional caster applications are very common in material transfer. They are very useful and very versatile for different kinds of applications. Here, we will talk about these systems and how to select these systems properly. And general application ideas that we can use these systems.

What is Multi Directional Caster?

Multi directional caster is a system that has the main axle that the general system is rotating around. And also this caster system includes little rollers at the circumference that provides rotation and move in other directions. So, they provide very big versatility in different kinds of applications.

Advantages of Multi Directional Caster Applications

There are different advantages of the multi directional caster applications that we need to consider.

- They provide 360 degrees of maneuverability to the different conveyor systems.

- The impact resistance is very high and the load capacity is very good for them.

- If we compare it with the ball transfer units, they provide much more ease while we are using them.

- The installation is very simple in general.

- Because of the multiple casters and rolling bearings, the load capacities are generally higher than the standard caster applications.

- Also, the load distribution over the wheels is very good for the different applications.

- If we use these multi-directional caster applications, the ability to tilt and lever off the system is very good in general.

- The wheel space housing requirements are minimal. Because they are not rotating. The little wheels help the movement in 360 degrees.

- The directional control and tracking are much better.

Disadvantages

Also, it is very important to consider the disadvantages of these applications.

- The biggest disadvantage of these systems, is they are generally higher in price if we compare them with the normal applications.

- The maintenance costs per part can be higher than the normal applications.

Applications

In different applications, youc can use et he multi directional caster systems. They are generally very useful for different kinds of applications.

- Paper industry: In the paper industry, use of the these systems is very common. Because the conveying systems and the manufacturing and packaging processes in the paper manufacturing systems are very complex. And the use of multi directional caster applications is very useful.

- Textile industry: Like in the paper industry, the conveying and transferring systems require the use of these systems.

- Packaging: If you watched videos about moving packages on the different conveyor systems, you saw that packages moving in different directions without any problem. This movement is generally made with the use of multi directional caster applications.

- Medical: Packaging and transferring systems are also very important in the manufacturing areas of medical applications. So, the use of multi directional casters is very common in this area.

- Movers: Also lots of people are replacing the old casters with the multi directional casters of the movers that they are using in the field. Because they provide much better maneuverability in general.

Selection Guide for Multi Directional Caster Applications

With these considerations and parameters, selecting the proper multi directional caster application for your system will be very easy for you. You need to assess all the parameters below according to the system to that you want to attach them.

Dimensional Considerations

These different dimensional parameters are very important in terms of if the system will adapt to your application.

- Wheel diameter: The total diameter of the wheel. Asses it according to the size of the system to that you want to attach it to.

- Wheel width: Select the proper width for the casing that you will attach. The wheel width shouldn’t be bigger than the caster casing of the system.

- Axle diameter: The system that you want to replace with multi directional caster applications have a standard axle diameter for the casters probably. Define this diameter and assess that you are using the correct application.

- Mounting hole diameter: You need to assess to select the required mounting hole diameter for different kinds of applications.

Design Parameters

These are the design parameters that you can consider about the use and the looks.

- Wheel type: Type of wheel application. The solid wheels do not have any treads in the mounting shaft. But other wheels have tread on the core.

- Color: You can choose the color of the wheels according to the styling or other kinds of occupational safety considerations. Some of the movers can have important signs that have different colors in general.

- Surface: You can consider which kind of surface you will use for the multi directional caster applications. Different designs are made for concrete, tile, asphalt, and so on. So, they will provide the best system that will be useful on these surfaces.

- Wheel location: Will you place the wheel on the lift or right? Do not forget to consider this important detail.

- Several rollers: The number of rollers around the wheel directly defines the smoothness of the movement and rotation. With the increasing number of rollers, the smoothness and the total weight capacity of the system increase.

Capacity Consideration

Also, you need to assess the maximum load that you are planning to carry with these systems. And you need to select the correct load-carrying capacity for the multi directional casters. In the capacity consideration, it is very important to know the total capacity per wheel. Because all the load can be on one wheel in different situations.

Material Consideration

In general, there are two different materials are available for multi directional caster applications.

- Acetal: It is a poılymer material that has very good abrasion resistance. It will be very useful for wheel applications.

- Polyurethane: The shock absorbing and abrasion resistance of the polyurethane material is superior.

Core Material; The core is the section that carries all the load that comes to the wheel. There are materials available such as nylon and polycarbonate. Both are very good in terms of load-carrying capacity.

Axle Material: Both brass and steel applications are available. The strength of the steel is higher. But in terms of rust and corrosion resistance, brass is superior.

Temperature Range

According to the environment in that you are using them, selecting the proper temperature range for these applications is very important. Check the maximum and minimum working temperatures of the muşti directional caster application that you are selecting.

Last Words on Multi Directional Caster

So, they may see very basic systems but there are different kinds of applications that we can use the multi directional caster applications. While you are deciding to use them, you need to consider the advantages and disadvantages.

Also, there are various kinds of parameters that you need to consider about these applications. Choosing the correct one will be very easy if you define these parameters according to the system that you design or replace.

If you have any comments or questions about the multi directional caster applications, please leave them below.