There are different types of steel materials available in the market. And we are using these materials in different kinds of applications. One of these steel types is free machining steel. Here, you can find detailed information about it and the features of this material. So, you will be able to learn the important details about this material.

What is Free Machining Steel?

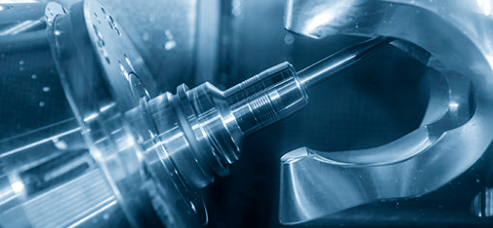

As you can understand from its name, free machining steel is a type of steel that we are using in machining operations. They are specially designed to obtain good machining properties from steel.

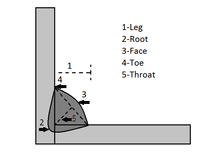

The difference of this material in the machining operations, we are getting many more different chip formations. In normal conditions and slow material removal rates, chip formation generally is continous. And this continuous chip formation can be problematic. Because they can physically block the machining operations. Free machining steel materials are very good in small chip formation in general.

Why Machinability is Important?

Importance of the machinability comes from the different kinds of parameters of the machişning operations.

For example one of the most important factors is the tool life. We are using cutting tools to create machining operations on different kinds of materials in general. So, if the total tool life increases the total money spent on the machining operation decreases.

Surface finish is also a very important characteristic of machinability. If the surface quality increases, we obtain a much more successful machining job. And we do not need to apply extra applications for the machining operations in general.

Because of this, we are generally making different kinds of adjustments and optimizations to improve the machinability of the cutting processes. One of these optimizations is the use of these materials.

Difference between the Free Machining Steel

To obtain the free machining steel, we are adding some additives to obtain these materials in general. Because of this, we can obtain the desired machinability property. These are the general differences.

- They are basic carbon steels to that we are adding sulfur, lead, bismuth selenium, tellurium, or phosphorus.

- Sulfur forms a compound with manganese sulfide. This is a very important thing that gives steel the chip creaking effect while machining.

- And these additives act as a dry lubricant while we are machining with different tools. So, tool life is enhanced in a much better way.

- The effect of bismuth is very different. It melts instantly with the application of heat with the cutting tool. And it acts as a machining lubricant in the machining operations.

Advantages and Disadvantages of Free Machining Steel

There are different kinds of advantages and disadvantages of this material in general. You can consider these advantages and disadvantages to deciding to use this material in the machining operations.

Advantages

- As we stated above the most important advantage of free machining steel, the machinability of this material is much more ehigher than that of conventional steel.

- Total machining capacity and the rate of machining increased with the increasing machining property of the steel. So, we can obtain much higher work in one pass.

Disadvantages

- The first disadvantage of free machining steel, their prices are generally higher than conventional steel. The price is generally higher % than 20. But with the increased machining speed and the tool life, it meets itself.

- Because of the extra additives inside this material, the ductility of this material decreased. So, the parts that we obtain are much more brittle from this material in general.

- Also, the impact resistance of the steel decreases if we convert it to free machining steel. This is also a very important parameter that we need to consider about these materials.

- If we are using these materials in the copper-based brazed joints they will suffer from embrittlement which is the effect of the reducing ductility for this material.

- If we create shrink-fit applications from these steels, the structural integrity will not be strong as we expected from them.

Types of Free Machining Steel

In general, we are examining the free machining steek applications in the 3 general groups.

11xx Series: The amount of sulfur is twofold if we compare it with the plain carbon steel applications in the 10xx series. Because of it, the machinability will increase % by 20 if we compare it with them. And also tensile strength of the steel will decrease with this addition.

12xx Series: In this series, the amount of sulfur further increases, and also Phosphorus is added. The machinability increased by over %40. But we are seeing a very big decrement in the material properties in general.

SEA 12L14: This is another important free machining steel application. We replace the Phosphorus with the Lead. This will increase the machinability % by 35. So we obtain very good machinabilities with this material. But Lead is generally banned because of the environmental damage that this material causes.

There are also other free machining alloys that are available in the market. For example, if we add Beryllium to Copper alloys, we obtain very good high machinability of copper alloy in general. And also if we add Lead to Brass alloy, we obtain free machining brass.

Conclusion

These are the general points that we can explain about this material. You just need to know that, the machinability increases, tool life increases, and the total machining time decreases. But you are paying as the decrement o the mechanical properties of the materials if you select the free machining steel.

If you have additional questions and comments, leave them below.

FAQs

We consider these materials as free machining steel because we obtain very good machinability with the addition of lead and sulfur to the structure of the plain carbon steel. But their mechanical properties of them decrease in a very bad way.

For different alloys such as steel, we obtain free machining grade by adding 0.2% of sulfur. This will increase the machinability of the steel to obtain a free machining grade in general.