Flange Gasket – Complete Guide, Selection and Types

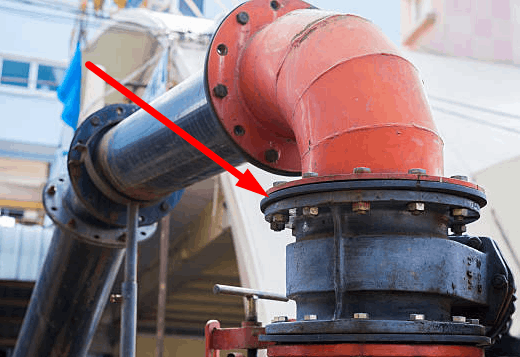

Gaskets are very important for different kinds of applications. These applications include high-pressure water or liquid transfer lines. These lines include different kinds of pipe connections which we call flanges. In these flanges, we use flange gasket applications. Here you can find detailed information about the flange gasket systems that are common in piping systems.

What is Flange Gasket?

As we stated above, the flange gasket applications are the systems that we use to create the required amount of sealing between the pipe connections. We use these pipes to transfer fluids between the systems. And these pipes are very important systems in general. So, the applications or gaskets provide a very important duty.

In general, they are made in the form of the shape of flanges. There are holes to which you can attach the fasteners through them.

Types of Flange Gaskets

There are different kinds of flange gasket applications are available in the market. According to the different parameters, there are differences in constructions and applications.

According to their materials and properties, there are 3 different types of them.

- Non-metallic: They are generally soft applications made from CNAF, PTFE, rubber, and ceramic fiber.

- Metallic: They are also a very hard application that is made in the shape of an oval ring or octagonal ring.

- Composite: With metallic and non-metallic materials, they create very durable flange gasket applications.

Non-Metallic Flange Gaskets

They are one of the most common flange gasket applications available in the market. They are very important systems that provide the required amount of sealing. In general, they are made from malleable materials such as elastomers, rubber, or flexible graphite.

The most important feature of these applications is low-pressure systems. And also the sealing area is the highest if we compare it with the other kinds of applications. In general, the pressure range for non-metallic applications is between 20 to 300 bar.

Metallic Systems

Also, metallic systems are very common for medium to high-pressure ranges. The main reason for this, they provide very good and hard sealing at the contacting surfaces. The shape of the sealing does not change abruptly with the tightened connections. So, very tight pipe connections can be made with these applications.

They are generally manufactured in a ring shape that provides very good sealing with a low contact area. The most common materials for them are the various grades of steel, chromium, molybdenum, copper, and soft irons. They are generally softer metals that get into the shape of the connection. But they are not malleable as the plastic and rubber applications.

Composite Gaskets

As you understand that composite flange gasket applications are generally made from both soft and hard materials. The outer section is generally made from soft materials that improve the sealing between the surfaces. And the internal section is made from hard metal that provides the required squeezing forces and pressures.

The most important advantage of composite gaskets, we can use them in a wide range of applications. They are very useful in different kinds of applications in general.

Important Considerations to Choose Flange Gasket Applications

If you need to choose a flange gasket application, you need to make these considerations in general. If you make these considerations well, it will be very easy to choose the best application for you.

- Pressure range: The pressure of the system is a very important parameter. Probably the available pressure range of the flange application is denoted. And choose the application that can withstand the highest pressure that can take place on the flange application.

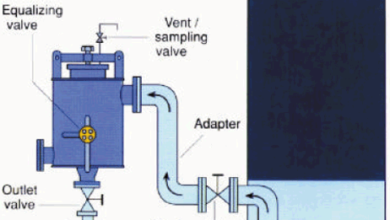

- Type: As you see above there are different types of gasket applications. And also the type of the flange connection is a very important parameter to consider. There are different flanges such as the raised face, flat face, ring joint face, etc. Be sure that the selected system applies to the type of flange.

- Temperature: At which temperature that you will operate the flange application? What is the maximum temperature of the fluid that flows inside the piping application? Choose a flange gasket application that can withstand the highest temperatures inside the piping application.

- Material: According to the parameters above, you need to choose the appropriate material that we gave the information about them.

- Bolt load: The system that you choose must withstand the bolt load which is very important to consider. Because of the increasing liquid pressure inside the piping system, the bolt load is also increased to provide the required amount of sealing to prevent leaks.

- Lifespan and maintenance: There will be important maintenance considerations about these systems. Because you need to make the maintenance and this is an additional cost on it.

- Cost: The cost of the flange application is also very important. And you need to solve this problem also. Do not consider buying low-price gasket applications compared with the general market prices. It will bring you low-quality applications.

It will be a very good idea to get different offers from different sellers and manufacturers. And you can easily assess the prices and performance between the systems.

Installation Guide of Flange Gasket Systems

The installation of the flanges is very important. You need to choose the correct flange application for these systems. They are very important systems that we need to apply in general.

- First of all, you need to be sure that the flange connection surfaces are clean enough. The contamination between the surfaces will prevent the ideal working of the flange applications.

- Place and align the gasket on the flange surface. Be sure all the fastener holes and the perimeter of the flange surface and gasket fit into each other.

- Align the flanges. Make the alignment of the two flange surfaces and the gasket.

- You can install the bolts and other fasteners.

- Test the system if there are leakages.

Conclusion

So, the flange gasket applications may seem like very basic systems. But there are very important considerations that we need to make if you want to select the correct application.

You can leave your thoughts about this topic below.

Check the other related topics about the gaskets;

Oil Cooler Gasket – Common Problems and Symptoms

Drain Plug Gasket – Replacement and Costs

Oil Filter Housing Gasket – What is That?