Double Torsion Spring – Uses, Advantages and Design

We are using spring applications in different kinds of mechanical design systems. They are generally very useful in strain-loading and force-carrying systems. There is a wide variety of spring applications. One of these applications is the double torsion spring type. Here, we generally explain the use of these types of springs, their features, and their design.

What is a Double Torsion Spring?

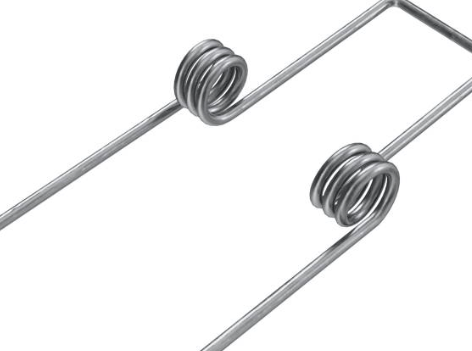

Double torsion spring is a type of spring that we are using in mechanical design. They are a variation of the single torsion springs. If we understand the working principles of these springs, it will be very easy for us to determine their features.

The general working principle of the torsion springs, they are useful in applications where we need counter-rotational force. There are nails of the torsion spring that are in contact with the discrete rotational elements. And the rotational torsion force of the spring nails holds the different rotational parts of the assemblies. When you try to open the part by rotating it, the counter-torsional force of the spring makes it come to the first position.

Between the nails of torsion springs, there are coils. these coils provide the torsional force when you exert a force on them. So, they provide very good back force to adjust the rotational parts to their first point.

The difference between the double torsion spring from the conventional ones, they have two coils. And there is the email between the coils that make the part close rotationally. The advantage of these two coils, they provide much more torsional force to close part.

If you need much higher rotational force, you can decide to use the double torsion springs in your designs.

Applications of Double Torsion Springs

The general applications that we are using the double torsion springs are generally the same as the conventional torsion springs.

Door Hinges

This is the most common application that we are using for these parts. If you look at the door hinges of automobiles, garages, and other door applications, you can find the application examples of the double torsion springs in general. Once you open the door and it closes by itself thanks to the double torsion springs.

Food Containers

Also in other daily applications, we see the double torsion springs. You can see the automatically closing lids of the food containers. When you open the lid and release it, it automatically closes. So, it is very easy to use in food containers in general.

Latches

In laundry latches, you can see the application of sing and double torsion springs. The lathes are held in the closed position while you are hanging the clothes that you washed.

Page Holders

Also, with the mechanisms of the page holders, you can see the applications of the double torsion springs. They stay in the closed position once to attach a sheet on them.

Design and Selection Considerations for Double Torsion Springs

You need to consider these parameters if you want to use the double torsion springs in your different applications. Also, while you are buying double torsion spring for different applications, consideration of these parameters and points are important.

- Wire Diameter: The diameter of the wire has a direct influence on the torsional force and moment on the application. With the increasing diameter, the torsion force will increase.

- Inner and Outer Diameter of Coil: They are very important structural considerations. You need to design your system that will include double torsion spring coils. Because you need to design it according to the sizes of the coil. You need to have structural support for the coil system to have a good design.

- Number of Coils: In a double torsion spring system, there are two coils. You need to define the number of coils. It is important for the turning capacity of your system.

- The Coil Bridge: Bridge is the system that will hold the lid or cap of the system. It is the nail between coils. You need to design or select the size of the coiled bridge according to your design.

- Leg Lengths and Angle: Legs are the systems that will hold the double torsion spring in balance. So, you need to know the angle and the lengths o these legs. Also, the ending type of the legs is very important.

These are the general parameters that will affect your selection and design. Also, you can easily design your system according to the standard manufacturing springs of the different manufacturers. If you have a piece of information about the standard springs that a company manufactures, you can easily use them to your advantage while you are designing your system.

Manufacturing of Double Coil Springs

If you understand how the double coil springs are manufactured, you can easily design a spring and take quotes from manufacturers.

In general CNC wire bending machines are very common in double coil spring manufacturing. And they can easily bend and create different kinds of shapes from the spring wires. So, if you design a custom spring according to the parameters above, you can explain it to the manufacturers. And manufacturers can easily manufacture them.

Conclusion

As you see above, you need to make different kinds of considerations if you use a double coil spring application in your mechanical design. This insightful information can make your design much more efficient.

If you have additional questions and comments, please leave them below! And also, you can find other insightful articles about mechanical design and machine parts on fmechanic.com!