Water Pump Gasket Guide

Gaskets and sealing elements are one of the most important parts of modern engines and general applications. And also water pump gasket applications are one of the most common things. Here you can find detailed information about the water pump gasket applications.

What is Water Pump Gasket?

A water pump gasket is a special gasket application that we use to seal the body o the water pumps. The water pump must pump and transfer the water to another place or higher elevation. And they make it by applying pressure on the water. So, inside the body of the water pump, the pressure is very high.

Also, most of the pump bodies are not made from a single part. There are separate body parts that we attach with fasteners. Between the body parts, we need to use sealing equipment to prevent the leaking of water or liquid to the outside because of the very high pressure. These elements are water pump gasket applications.

General Materials for Water Pump Gaskets

There are different kinds of materials are available for water pump gasket applications. You need to choose a proper one according to the requirements of different applications.

- Rubber: Rubber is one of the most common gasket materials that is used. It is a highly flexible material that provides excellent sealing for water pumps. And also, they are resistant to oil, heat, and chemical. In harsh environments, they show excellent performance.

- Paper: Mabe you hear this material for the first time. The use of paper is very common as a water pump gasket. For low-pressure applications, paper gaskets are very common. If you are looking for a low-price gasket application that will be temporary, you can look for paper material. Also, they are not durable as rubber gaskets.

- Cork: Cork gaskets are generally used for high-temperature applications. They provide extra resistance to very high temperatures. And also they provide very good sealing.

- Silicone: One of the most developed materials to use as a water pump gasket. Like rubber material, they can withstand high temperatures and chemical attacks. But if you need to use an advanced gasket material for extreme temperatures for high-temperature engines, you can consider using silicone material.

- Metal: In general, the interconnection of the pump casing is cast metal which is a highly brittle application. So they have very low sealing features. So, the use of malleable metals such as low-carbon steels, and coppers are common applications for water pump sealing. They have the longest service life if we compare them with the other applications.

So according to the different kinds of applications and different external and internal conditions, it is very important to choose the correct water pump gasket material.

How to Choose the Best Water Pump Gasket?

There are different things that you need to consider about water pump gasket applications in general. If you make these considerations, it will be very easy to choose the best application for yourself.

- Pressure: The maximum pressure inside the pump is a very important parameter. In general, the water pump gaskets have different pressure ranges that they can withstand. And you need to know the maximum pressure that takes place in the system and choose the gasket according to that.

- Chemical compatibility: Yes, you are probably pumğing water. Buy water is a very corrosive liquid even if it is high pressure in general. So, it is very important to withstand these chemical attacks for a gasket. For example, if you choose a metal gasket for seawater, it is not a good idea. Because the sea water or salty water will deteriorate the metal.

- Durability: As an engineer, you need to choose the most durable application. It is very important to know the general things about the lifespan of the gasket. And you need to know in which periods you need to change that gasket. It will be better to choose high-quality and durable materials and applications.

- Temperature: Like pressure, the working temperature of the pımp system is very important. And water pump gasket applications have different kinds of available working temperatures. So, you need to choose an application that provides very good working conditions. So, consider the applications that will provide a very good working temperature.

- Cost: You need to take offers from different water pump gasket manufacturers. And you need to assess the different ones. Choosing the best application will be a very important thing to consider.

By ömaling these important considerations, it will be very easy to choose the best application for yourself and the pump application.

Replacement Tips for Water Pump Gaskets

Removing the water pump gasket is not an easy thing first of all. Because you need to be familiar with car mechanics in general.

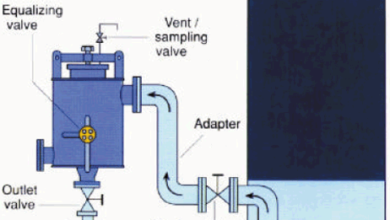

- Drain the system: Once you stop the pump system, you need to drain the water inside the pump for dealing with the gasket. You can do it by taking the pressure from the piping system. To remove the pump from the pipe system, you need to rip the flange bolts off.

- Removing old gaskets: At the attachment points on these flanges, there will be old gaskets that are generally ripped and damaged through time. You need to remove the old gasket. Also, you need to remove the gasket on the pump casing.

- Clean the surface: Clean the attachment surfaces thoroughly with a help of a brush to be sure that there are no other pieces or things to prevent the sealing.

- Install the new gasket: Attach the new gasket thoroughly. Be sure that the holes are aligned with the bolt hoses.

- Reinstall the pump: Reinstall the pump with new gaskets to int place again.

- Test: Make a small test if the sealing of the gaskets is working well at the h, highest pressure.

This is a very important maintenance tip for pumps in general.

What Causes Them to Leak?

There are different reasons for the leaks.

The first and the most common cause is the reaching its end of life. When the declared lifespan of the gasket is over, you can see that the pump is leaking.

Another important reason is the working conditions that are very high if we compared with the generally explained working considitşns of the selected water pump gasket. Because of this reason, there can be damage taking place on the structures of the water pump gasket applications.

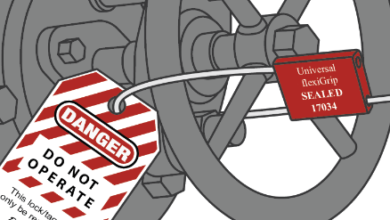

External damages can also very important thing to consider. There can be hammer damage on the seal application in the maintenance can cause leaks. And also overtightening the fasteners can cause damage.

How Serious is a Water Pump Leak?

It depends on the level of leak that takes place in the water pump application. If the water pump application leaks lots of water from the gasket, you need to immediately change it with a new one. Because the pump consumes much higher energy to increase the pressure of water. And if there is a big leak, the pressure of the water will not increase. This can cause damage to the electric motor of the pump. And also the energy bills will be much higher.

The water leaks can cause cavitations also. Pumps are generally designed to work at specific pressures and temperatures. And if the intended pressure will not take place as intended, this will be very harmful thing for the pump blades.

So, it is very important to consider the leaks if the level of the leaks is at a very high level.

How Do I Know If My Water Pump Seal Leaking?

First of all, you can understand it with visual observation. There will be wet areas on the pump and the other components which means the tour system is leaking. To find the exact location, you can use a soapy technique. Just apply soap to the wet area and see where bubbles are forming. This will show you the location of the seal that leaks.

Conclusion

These are the general things that we can consider about the water pump gasket applications. They may seem very basic systems but there are different kinds of considerations that you need to make if you need to choose.

If you have additional comments or questions about the water pump gasket applications, please leave them below.

Check the related topics about pumps;

Heat Pump Water Heater vs Tankless Water Heaters

Tankless Water Heater Recirculation Pump – General Overview