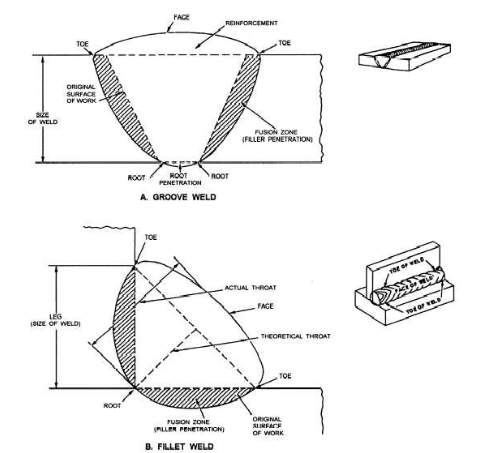

Parts of a Weld – Both Fillet and Groove Welding

Welding is a very important application in engineirng and contruciton applications. There aree different types of welding applications available. And we are analyzing the welding applications in different manners. Here, we will take a look at the different parts of a weld joints and their meanings in general.

What are the Parts of a Weld?

Both for fillet and groove welding applications we are defining the different kinds of places of them. And while we are examining the quality of welding, we are examning the parts of a weld.

Fillet Weld

Fillet welding is a type of welding that we are joining two straight metal parts in 90 or 120 degrees. Also we call these systems are the T joints. While applying the welding om these type of materials, we apply welding on two corners and generally two minimum passses. These are the general parts of a fillet one.

- Weld Toe: This is the transition zone of the welding material to teh base material. You can see it as a toe shape. And we want this transition soft to obtain high quality welding.

- Weld Leg: Weld leg is the connection face of the weld material and the welded plates. The broader the weld leg, the much more higher strength of the welding.

- Weld Face: The external surface of the welding material in the T joints. In a good weld, you can see this as a slighly curved way.

- Weld Root: The section of the weldmaterial that comes contact with the corner of teh T joint. The weld material must fill this section very well to obtain a very good welding.

- Theoritical Throat: The theoritical minimum distance between the weldiing face and the toor of the welding. While applyimng the welding, this is the intended throat distance that we want.

- Effective Throat: This is a value that is same with teh theoritical throat value. Some people also name it with this way.

- Actual Throat: The distance of the real throat that occurs because of the curvature of the weld face.

Groove Weld

Some people also know the groove one as the butt weld joints. We are joining two pieces to face to face each other and apply the welding between them. These are the general sections that we design in the groove one applications.

- Reinforcement: Section of the groove weld metal that excess the surface of the butt weld. This is the extra material that provides reinforcement to the joiint.

- Heat Affected Zone: This is the part of the butt weld material that it is not melted. But the microstructural and physical properties are changed because of the heat.

- Weld Root: The bottomside of the welded section.

- Joint Root: This is the section of the groove welded parts that closest joint points.

While we are makingf calculations about them, we are generally thinking about these parts. And these are the important things that we need to consider about the parts of a weld.

Also, to make stronger the heat affected zone, we are applying multiple passes to make stronger the welded joint. This provides us a very good and high strength joining system in general.

Last Words

As you see above, the parts of a weld changes according to the type of the welding that we are applying. While we are talking about the welding systems, we are generally using these terms to specify the different things about welds.

If you have additional questions about this topic, please let us know in the comment section below.

You can find related articles and blog posts about this topic in here;