How to Clean an Electric Motor? Easy Steps!

Electric motors have a very important duty in the modern life of humankind. They serve very important different kinds of duties to give power to different kinds of mechanisms that we have from the smallest to the biggest. And generally, the working principles of these electric motors are saying. Because of it, lots of people are looking for a solution to how to clean an electric motor. Here we will explain the different kinds of steps that you can follow while you are cleaning your electric motor.

How to clean an electric motor?

First of all, we need to state that dealing with electrical parts such as electric motors has a very safety issue that you need to take care of. If there is an accident you will be affected and shocked by the electrical current, so you need to take the important precautions before dealing

with the cleaning and electric motor.

First of all, you need to wear shoes that are made from rubber to prevent any electrical shocks, and wear plastic hand gloves for the electric works. Another safety thing that you need to take care of is to wear safety glasses because the electrical motor has very small parts that you need to deal with, and if these small parts will eject from the system they can harm your eyes.

Once you have taken the required amount of safety precautions that we explained, you can start to apply these steps;

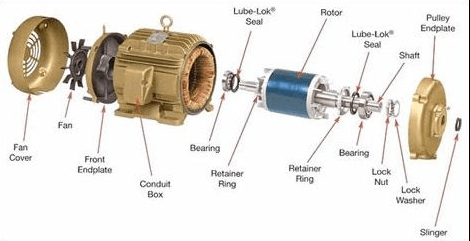

Step 1: You need to disconnect the electrical motor from its place. The electrical motor has a steel or test casing that is attached with different kinds of fasteners to the main body of the component. You need to detach these fasteners by using appropriate keys or screwdrivers, but before doing it, you need to be sure that you disconnected the electrical supply to the system. Also, you need to disconnect the electrical supply from the electric motor. The electrical supply is generally connected with a cable to the one end of an electrical motor. Disconnecting this cable is a very easy thing you need to take it gently from its place.

Step 2: Disconnecting the electric motor from its place, there will be a casing that you will see different kinds of wires and terminals inside it. It will have a very easy chasing that you can detach the electrical motor from its fasteners by using screwdrivers or keys. These terminals are generally connected with electrical nuts. You just need to gently remove these electrical connections and you need to take note to place all these terminals.

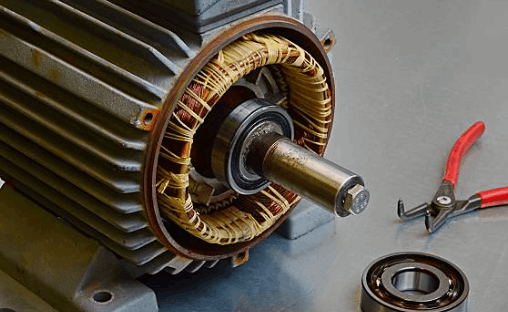

Step 3: If you take a look at one end of the motor, you will see a shaft attachment system which is generally a pulley system. By using an appropriate gear puller which you can find in different marketplaces, you need to remove that gear puller to remove the shaft system of the electric motor. In some systems, there will be no pulley system that you need to remove from the electric motor. If there is no pulley system, you just need to pass to the other step.

Step 4: To both sides of the electric motor, there will be specific cases that are attached with fasteners or screws. Before detaching these housings, you need to mark the places of the fasteners. After cleaning, you need to spot the same places again. Just remove these attachments by using the appropriate Allen keys. Once you remove the bolt housings at the different ends of the electric motor, you will see that one housing carries the shaft system and also the rotor system on it.

Step 5: You need to act very gently while you are removing it, and once you see all the components, you can start to clean it. First of all, you shouldn’t use any affiliates or cleaning agents while you are cleaning the complex copper wire systems on the rotor and the stator system of the electric motor. You need to have a very fine grit cleaning cloth. You can start cleaning clearances between the copper wire systems and the internal systems in a very gentle way, and you need to be sure that you do not harm the copper systems inside it. If there is a problem in the copper system, this means you cannot fix it on your own, and the electrical motor will be non-usable because of this problem.

Step 6: While cleaning the external housings of the electric motor, you can use cleaning agents that are not harmful to the external structure, and you need to be sure that you are not mixing the cleaning agent with the internal system of the electric motor. Be sure that you drive the old cleaning agents to the external system.

Step 7: Once you are sure that the electrical motor is cleaned, you need to reattach all the parts to their places again. You should start by attaching both ends housing to each other, and the places of the fasteners must stay where you marked while you were ripping off the electrical motor, and you need to be sure that the shaft system will fit to the other end correctly. Attach the fasteners of the housings and attach the pulley that the shaft is attached to the electrical motor. Then attach the terminals to their places again. After that, you can attach the electric motor to its place again by using its fasteners and you can attach the power source to the electric motor. Before giving any power to the system, you need to test if the electric motor works well by turning the shaft with your hand. If it rotates without any problem, the operation is successful.

Is WD-40 good for electric motors?

So lots of people are asking about this question because WD-40 is used in different kinds of mechanical systems. We do not recommend using WD-40 in electrical motors, especially in the internal parts. It can harm the electrical system and the terminals. Short circuits can be very problematic if you use WD-40 in the internal systems.

Can you clean an electric motor with alcohol?

This isn’t also a very common question, but at the state level, do not use any fluids while you are dealing with the internal systems, complex copper windings, and other electrical terminals because you can lead to a problem of short circuits and it can lead to very bad accidents. And do not use detergents but for the external casing of your electric motor. While you are cleaning the internal copper windings and electrical terminals of the electric motor, you need to use completely dry cloths or systems.

Conclusion

These are the general steps that we can state about the cleaning of an electric motor in general. Cleaning of an electric motor is not an easy stuff and you need to have a very good understanding of the electrical system in general, and also you need to take care of the safety system save the issues that we explained about.

If you have additional comments and questions about how to clean an electric motor, you can leave them below without any hesitation.

Also, you can check the similar articles and similar contents about the electric motors and electrical systems that are available on this website.