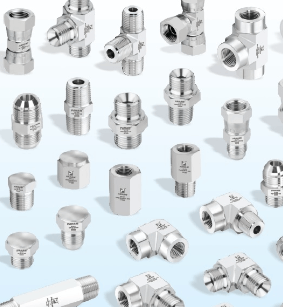

High Pressure Fittings

Pressure is a very important parameter in fitting and plumbing applicaitons. Because the main thing that we expect from fittings is the sealing. But with the increasing pressures, the sealing capacity of the different kinds of elements decreases. Here we will talk about high-pressure fittings ad their general uses and parts.

What are High-Pressure Fittings?

High-pressure fittings is an application that we are using for high-pressure applicaitons. The pressures can reach up to 200.000 psi which is very high for ordinary fitting elements. So, there are different manufacturers manufacturing these systems and parts for these systems.

What are the High-Pressure Fitting Applications?

In general, we use fittings to transfer the fluids between different systems. These fluids can be gases or liquids. Also, control of these gases and fluids can be made with the different fitting elements. So, if the pressure of the fluids and liquids are very high such as between 5000-200000 psi, we classify them as high-pressure fittings.

- Steam systems: In power plants, high-pressure and temperature steam is generated and used to rotate the turbines. So, handling this high-pressure steam between the different systems is very common. We are making this by using high-pressure fittings.

- Hydraulic systems: Also in hydraulic systems, the use of high-pressure fittings is very common. Because the hydraulic liquid inside the hydraulic system transfer motion between the hydraulic parts. So, their pressure is very high, and tight systems needed to be used in these systems.

- Water and gas grids: In city water and gas grids, the pressure of the şiquids is very high to transfer them for kilometers to different houses and buildings. So, the use of high-pressure equipment is very common in general.

- Industry: In the manufacturing industry, we use high-pressure and temperature liquids for different kinds of applications. And the use of high-pressure fittings is very common in general.

General High-Pressure Fittings Elements

In these systems, we are using different kinds of elements and applications.

- Stainless steel tubes and pipes: In high-pressure applications, we generally use stainless steel tuıbes and pipes. Because this material has a very good structural strength to withstand the highest pressures.

- Couplings: For the connections in fitting applications, we are using couplings to connect the different tubes and pipes. They are designed in a special way to withstand high pressures in general.

- Adapters: If we need to change the diameters of the tubes and fittings, we use high-pressure adapters in general.

- Valves: To control the flow of the fluid inside these systems, we use high-pressure valves in general.

Conclusion

These are the general points that we can state about high-pressure fittings. If you have additional comments and questions about these systems, please leave them below.

And also, you can find other kinds of useful posts and articles about these systems on fmechanic.com!

Threaded Tube – Selection Guide