Coil Rod Systems – For Versatile Construction Applications

Creating custom structures and different kinds of applications is very important in different kinds of applications. We generally use different kinds of parts and mechanical systems for these applications. One of these systems is the coil rod system. Here, we will take a smaller look at these systems.

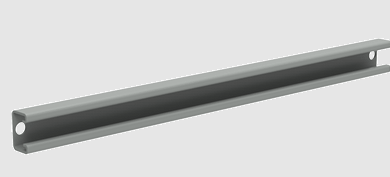

What is Coil Rod?

A coil rod is a long bar that has external thread geometry on them. We can attach different nuts and clamps to these applications. In general, we are using them in concrete forming applications to obtain concrete mold systems.

In general, we are using these systems with coil nut washers and coil nuts. And with different applications and structures, we can create custom structures to give shape to the concrete systems.

Different Sizes of Coil Rod Applications

According to the type of applications, there are different kinds and sizes of coil rod systems that we can select.

The general diameter of the systems are 1/2″-6, 3/4″-4 1/2, and 1″- 3 1/2.

The general thread is the right-hand thread that is available for different standards of the different nuts and bolts.

You can find different lengths of them in the market starting from 6ft to 12ft. And the prices change between $40 to $310 according to the diameter and the length of them.

The general applications are zinc coated to prevent corrosion in the open atmosphere.

Applications We Use Coil Rod Systems

There are different kinds of applications that we use the coil rod systems. If you know these applications, it will be very easy for you to choose the best one for different applications.

- In construction applications, the use of coil rod systems is a very common system that we use inside concrete formworks. They are temğpprary applications to the structure in place uıp top concrete sets. So, this application makes them very important in most systems.

- Also in pile foundations, we use coil rod applications very commonly. Because of it, their use is very common in these systems. They provide additional reinforcement to these systems in general.

- In retaining wall applications, lateral pressure is a very common problem from the soil or water. And the coil rod applications are very useful for this system to add extra reinforcement. Because the metal structure makes the brittle concrete application much more durable. It is very important to use them correctly.

- Tunnel linings are also made from concrete applications. So, the use of them is very common in tunnel linings to withstand very heavy loads coming from the soil from the upside. And the most reinforced and durable ones are used in these applications.

- You know that bridge decks are made from concrete asphalt applications. They need to have an important amount of reinforcement to deal with very high loads coming from the vehicles on them. To obtain both fşexible and high durability applications, the use of coil rods is very common in bridge deck applications.

- If we are using concrete slabs on different constructional areas, the use of them is very common in their applications.

As you see above there are different kinds of areas in which we use coil rod systems.

What to Look for While Choosing Them?

If you are an engineer or architect, it is very important to choose the correct coil rod application for your project. You need to make general calculations to choose the best one. And if you make these considerations in general, choosing the best one will be very easy for you. Here you can consider these important things before selecting the best applications;

- Grade: There are different grades of coil rod applications available. You can find them as low-grade, medium-grade, or high-grade. With the increasing grade, the strength and durability of the coil rod applications increase. So, you need to choose the best grade for coil rod applications in general. And you do not need to choose the highest grade for all the projects.

- Geometry: Diament and the length of these applications are also very important. In general, coil rod applications are very long systems. And you need to choose the correct learning. Also, diameter is very important. With the increasing sizes of buildings, the diameter of the coil rod increases.

- Surface treatments: There are different surface treatments and costings applied to the coil rod applications. For example, the use of epoxy and galvanized surface are very common to prevent corrosion. According to the working environment, it is very important to choose the best application. If you will use them in corrosive environments, you need to choose special applications.

- Manufacturer: Where this coil rod application is manufactured? It is a very important question to ask. You need to be sure about the quality o the materials. It is very important to look at the general projects in which these applications are used.

- Price: You need to take offers from different coil rod manufacturers. And according to the different parameters that you consider, you need to choose the best application that you need in general. Also, you need to know that, increasing the price does not mean the increasing quality. But decreasing price always means decreasing quality. You need to choose the best price/performance application.

Building structures is a very important task. Also if you are building these structures in earthquake zones, it is very important to choose the best application and comply with the general regulations about the buildings. So, it will be possible to build the best and the most strong structures by using coil rods.

Conclusion

Coil rods are very basic systems that make it possible for adjusting the different kinds of custom structures to obtain the bridge systems, concrete shaping systems, and so on. You can find different sellers and they give prices in a piecewise manner.

If you have additional questions about the coil rod applications, please leave them below!

You can also find other useful and insightful applications about mechanical systems for different applications on Fmechanic.com!

Fuel Tank Strap – Questions and Answers