CO2 Tank Regulator – Different Types and Applications

For CO2 tanks we need to use regulators to control the flow of the CO2 inside the tank. Otherwise, it will be very dangerous. A rapid expansion could take place. Here you can find different applications and types of CO2 tank regulator systems that you can use for tanks.

Different CO2 Tank Regulator Applications

Check the features and prices of these different CO2 tank regulator systems so that you can select the best one for you.

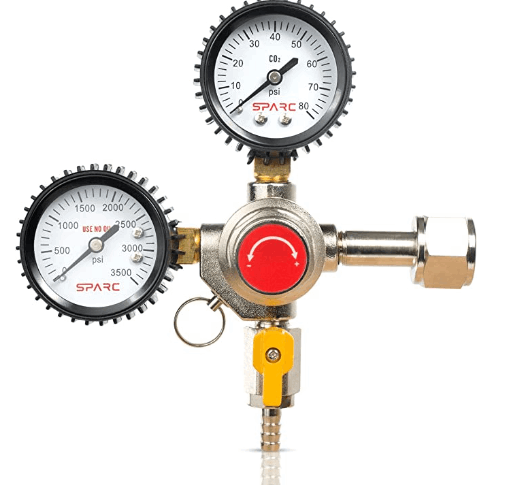

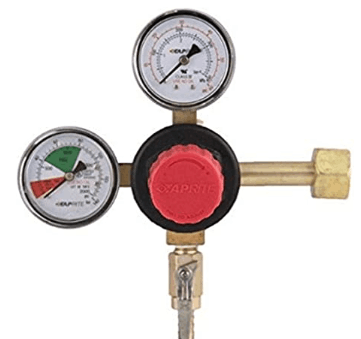

SPARC Premium CO2 Regulator

CO2 Tank Regulator

- 2 gauge setup.

- CGA-320 outlets.

- Easy control.

This one is one of the most common CO2 tank regulator applications. You can easily measure the C2 pressure inside brew tanks and barrels. And you can easily control the CO2 inside the barrel.

- With the know at the front side, you can easily adjust the CO2 inside the tank.

- You can use them with CGA-320 standard tank outlets.

- You can easily attach this regulator to the pressure tank with a gas shut-off valve.

- For different kinds of kegs, it is applicable.

- From the same seller, you can find a dual CO2 tank regulator also.

- It comes with 2 years of manufacturer’s warranty.

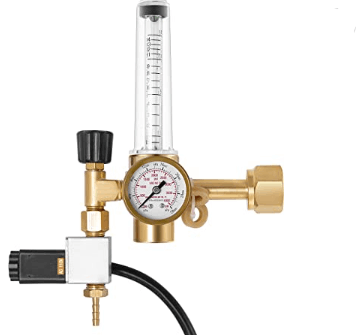

VIVOSUN Hydroponics CO2 Regulator Emitter System

CO2 Regulator

- Solenoid valve control.

- Brass components.

- 4000 psi pressure.

If you are looking for a CO2 regulşator and emitter system for tents and gardens, you can consider this product. You can use it for controlled emission application of CO2 that you can easily use. So, use of them is very easy in general.

- It has a very high-pressure range of up to 4000 psi.

- Brass material provides a very high-quality application.

- The industrial solenoid valve controls the flow of CO2 to the environment.

- With the free dispensing tubing, it is very easy to use.

- 4.2 mm of hose diameter.

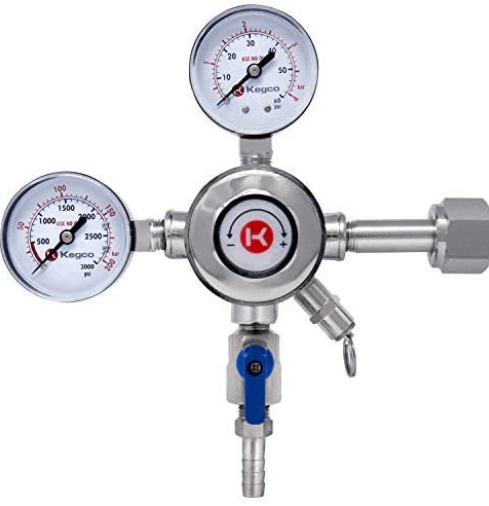

Kegco KC LH-542 Draft Beer Regulator

Keg Regulator

- Dual gauge system with working pressure and tank pressure.

- Chrome plated.

- Manual release valve.

- 45 psi release.

This one is another regulator that you can use for home kegs. There is a pressure relief valve that will release the CO2 inside the barrel at 45 psi. And also there are two gauges that you can read the working pressure and the inside pressure.

- The chromium-coated brass body makes it very easy to apply for different kinds of systems.

- You can use the manual pressure relief valve without any problem.

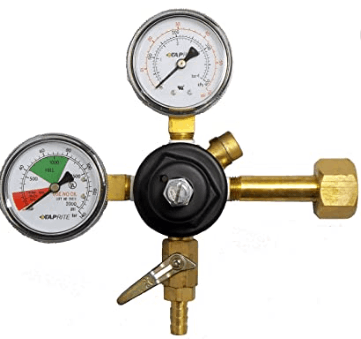

Primary Double Gauge CO2 Tank Regulator

Double Gauge Tank Regulator

- High-quality application.

- Low-pressure gauge.

- 50 psi working pressure.

This one is another common CO2 tank regulator application that you can buy. There are two gauge systems that you can read both the working pressure and the tank pressure.

- The maximum delivery pressure is 50 psi.

- The duckbill check valve prevents the backup to the system.

- The side gauge that shows the pressure of the tank indicated how much CO2 remained in the tank.

Taprite Co2 Primary Regulator

Double Gauge Tank Regulator

- 1/4″ barbed shut-off valve.

- CGA 320 standard inlet.

You can also use this CO2 regulator for different kinds of brewing applicaitons. Like the other systems, there are two indicators showing the pressure of the tank and the working pressure.

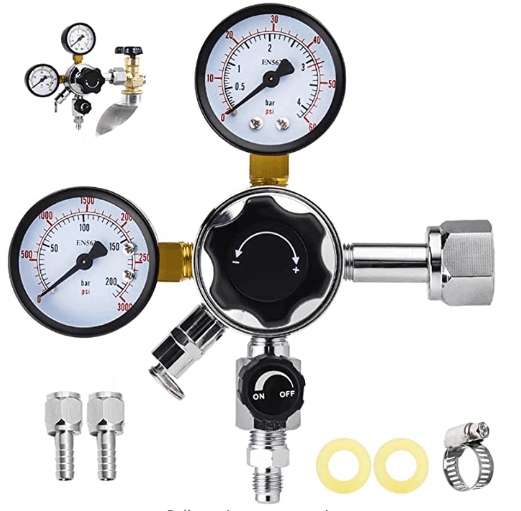

MRbrew CGA-320 Keg CO2 Tank Regulator

1/4’’ & 5/16’’ Barb Regulator

- Relief valve.

- Threaded end fitting.

- CGA 320 inlet.

This is an anti-backflow high-quality CO2 tank regulator that you can use for brewing applications. The maximum working pressure is 45 psi that you can use for brewing in kegs. Also, the CGA 320 inlet makes it possible to use in standard inlet applications.

Dual System 2 Stage CO2 Pressure Regulator

Dual Regulator

- For dual connections.

- Best for multiple applications.

Also, the use of dual regulator systems is very common in most different kinds of applications. If you want to control the flow of CO2 for different kinds of applications you can use dual regulators.

- CGA 320 connection makes it very easy to use for standard applications.

- You can control 2 different kegs with one CO2 tank.

Important Points to Consider

First of all, we need to state that we are using the CO2 tank regulator applications to use high-pressure CO2 tanks. Inside the high-pressure tanks, we can take the CO2 inside them at a specific pressure. In general, there are two gauges that show two different pressure values. The first one shows the pressure of the CO2 inside the tank. From this pressure, we can understand how much CO2 is left inside the tank.

The second one shows the pressure of the CO2 flow. from the tank. With the knob at the front side, we can adjust the flow pressure of the gas. Most of the applications are 45-50 psi maximum working pressures.

Also, the connection type is very important. There are products with CGA 320 and CGA 580 inlets. So, you need to be sure that these inlets are the same as the regulators.

Conclusion

These are the general points that we can state about the CO2 tank regulator systems. If you have additional comments and questions about them, please leave them below.

And also, you can find other kinds of useful articles and posts about valves and other systems on fmechanic.com!

Hose Valve Systems – Selection Guide

AC Valve Systems in Car – Duty and Replacement Costs

Ball Check Valve System – Applications and Problem Solutions