Ball Check Valve System – Applications and Problem Solutions

There is a wide variety of valve systems that are available for different kinds of applications. One of these types is the ball check valve system. They are a very useful system that we are using for different applications. Here, we will take a look at the ball check valve and its general problems and important points.

What is a Ball Check Valve?

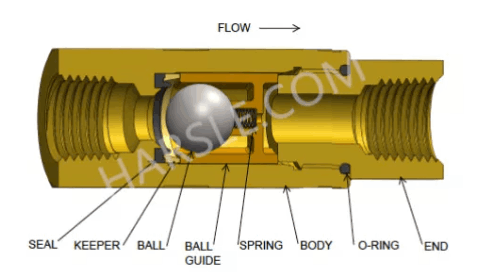

We use check vaşve systems to prevent backflow in the fluid flow applications. They allow the fluid to flow only in one direction. And if there is a backflow from the opposite direction, the check valve does not allow for that flow.

The ball check valve is another important type of check valve. There is a ball inside the valve system. And the ball is free to move up and down. At the bottom side, the flowing fluid comes to the chamber. Once the fluid flow starts, the ball floats to the side. And fluid flow continues. And if there is any reverse flow in the system, the ball sinks to the floor and closes the hole from which the fluid flow comes. So, they prevent the backflow which this mechanism.

Important Points to Know About Ball Check Valve Systems

There are different kinds of points that we need to know about these applications. In general, some of the manufacturers manufacture them as a self-cleaning feature. They make it with the rotation during the fluid flow.

The calcification and the accumulation of dirt can be a problematic issues on the ball mechanism. But if the ball rotates with the fluid flow, the calcification and dirt accumulation will be very low.

Also, the precision of the ball check valve systems is a very important point. After how much back pressure that the valve prevents the back pressure? You need to answer that question. And you need to know the maximum allowed back pressure of your system while you are selecting an application.

And also, the balls are generally made from a steel core that is coated with polymer materials such as polyurethane. They provide very good sealing and very good abrasion resistance. You need to be sure about the abrasion resistance capacity of the ball check valve system that you are looking for.

Importance of Ball Weight

The ball weight is a very important parameter while you are selecting these systems. There are two reasons.

Water Hammer Effect

The water hammer effect can be a problematic issue when you are using the wrong ball weight. If you select a lower ball weight than required, you will start to hear a tickling sound from the valve system. This is the water hammer effect caused by the pressure spikes. This can hurt the valve system in a very bad way. The manufacturers generally recommend that you need to test by increasing the ball weight by +20% in each trial to prevent the water hammer effect.

Vibrations on Ball Check Valve

Vibrations can also be a serious problem. This is generally caused by the high weight of the ball. You need to apply the same principle by decreasing the ball weight and testing any problems that you have.

Once you find the optimum ball weight for your check valve application, you can choose the best one for your system.

The material of the casing equipment must be corrosion-resistant and acid resistant to resist the flowing fluid. In general, they are using ductile iron materials.

Also, you need to check the standards. If you will use the application in your engineering system, you need to check for the standards. For example, DN 600 is a very important standardization for ball check valve applications.

Prices of Ball Check Valve Systems

In general, the prices change according to the different types and capacities. Commercial manufacturers are generally working with an offer system. You just explain your needs and the quantity of them, and they will send you a provision. So, you will be able to see the general prices of the check ball valve system.

But if you are looking for basic systems, you can find them with prices ranging from $15-60 on Amazon.com.

Last Words

This is the general information that you need to be aware of about the ball check valve systems. If you have any comments or questions, please leave them below.

Also, you can find other useful information about the hydraulic and valve systems on fmechanic.com!

Spring Lock Washer – Differences, Types, and Materials