Type E Thermocouple – Uses, Advantages and Differences

There are different types of thermocouple applications that are available in the market. We are using these thermocouple types in different kinds of applications. And one of these types is the type E thermocouple. You can find detailed information about this type in here.

Important Features of Type E Thermocouple

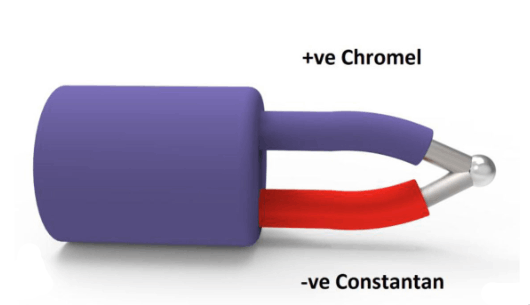

Different features of the type E thermocouple make it possible to use in different applications. The composition of the type E thermocouple is the Nickel-Constantan material couple.

The most important feature of the type E thermocouple is, they provide much better accuracy in applications where moderate temperatures. And if we compare type J and type K, they are better in terms of accuracy.

Also, the EMF produced for temperatures degrees is much more ehigher which provides much higher accuracies.

The high output of Type E makes it possible to obtain correct results. The value is 68μV/°C which is very high if we compare it with other systems.

Also, it has very high corrosion resistance that we can use in corrosive environments. The non-magnetic nature provides added quality in the temperature measurements in the magnetic fields.

Special Uses of Type E Thermocouples Systems

These are the special uses that the type E thermocouple that shows the best performance over others.

- In flow chamber applications, they are suitable for gas low temperatures. So, the use they are very suitable for steam and hot gas systems.

- If there are magnetic fields because of some reason, it will be much better to select these types. Because these types do not affect by the magnetic field.

- Industries such as aerospace and automotive, are performing very well because of the fast response required.

- They are best for cryogenic applications because they show high accuracy in low-temperature ranges.

Types of Type E Thermocouple Systems

There are also different types of type E thermocouple.

- MgO Insulated: It has a magnesium oxide insulation that provides superior high-temperature durability.

- Cable Type: They are made from flexible cables, PVC, and PTFE to use in flexible systems in general.

- Metal Sheath: The metal sheath provides probability to use in high-temperature applications.

For laboratory applications, we generally decide to use MgO insulation. There are different advantages of magnesium oxide insulation on them;

- This insulation increases the temperature range that we can use. Because MgO is a temperature-resistant material that we can use in the applications.

- They are also very resistant to thermal shocks. It makes it possible to use in high-temperature applications.

- Vibration resistance is also another important feature that we need to state about this insulation. The vibrational effects can affect the accuracy of the measurements. So, the use of the MgO increases the accuracy.

Temperature Range

- Thermocouple grade wire, -454 to 1600°F (-270 to 870°C)

- Extension wire, 32 to 392°F (0 to 200°C)

Advantages and Disadvantages of the Type E Thermocouple

Also, there are advantages and disadvantages of the type e thermocouples. While you are selecting a type of them, you need to consider the advantages and disadvantages of them.

Advantages

- The most important advantage is, the accuracy o the type E thermocouple is much higher than the other types.

- The response speed of this type of thermocouple is very high.

- The high output provides a stable output in a wide range of temperature measurements.

- You can use them in sub-zero and oxidizing environments.

Disadvantages

- In a vacuumed environment, they do not show good performance and accuracy.

- In the Sulphuric environment, they are not showing good performance.

- The general costs are higher than the other types of thermocouples. You need to assess the level of accuracy and which kinds of environments you will use to select the best one for you.

Conclusion

As you see above, type E thermocouple systems are very good for specific systems. You can select them for these applications. And also, there are important points that you should not select such as the sulphuric environment and vacuum.

If you have additional questions and comments, please leave your thoughts below.

You can find similar and useful content on fmechanic.com!