Stop and Waste Valve – All Things to Know!

Valve systems are very common in different kinds of plumbing and HVAC applications. So, they are very important systems that we can control the flow of fluids. There are different types of valves are available in general. Stop and waste valve applications are one of them. Here you can find detailed information about the stop and waste valve applications that we use in plumbing and irrigation systems.

What is Stop and Waste Valve?

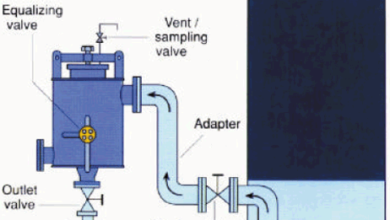

They are very basic systems that we use to control the flow of water through a piping system. There is a handle that we turn and stop the fluid flow. And also there is another handle that we turn to drain the remaining water inside the piping system.

So, they are useful in such applications. The name “Stop and Waste” probably comes from one handle to stop the fluid flow, and another handle to drain the water inside the system. Once you open the handle, the drain or “waste” of the remaining water takes place. The origination of name comes from it.

The drain handle can be very useful for such applications that operate in winter and cold environments. Because it prevents the freeze of the water inside the pipe and the irrigation system to prevent freezing and damaging system.

Applications that We Use

There are different kinds of applications that these very useful systems. Especially in outdoor plumbing applications, their uses are very common in general.

- Irrigation systems: The use of stop and waster valves are very common in outdoor irrigation systems. Especially in the sprinklers that we use to water the grass, we control the flow of water to these systems.

- Outdoor faucets: Also the use of the stop and waste valve is very common for outdoor faucets. You know that we need to drain the remaining water inside the outdoor faucets when we do not use them.

- Fire systems: You may see lots of fire protection systems in an outdoor environment. The use of stop and waste valve applications is very common in these fire protection systems.

- Industrial plumbing: Also in industrial plumbing applications, the use of these systems is very common. They provide a very good application for different kinds of systems.

Symptoms of Bad Stop and Waste Valve

In general, these applications are very long-lasting systems that you can use for long years. But, if you see these symptoms, it means you need to change the valve application with a new one.

- Leak: For all types of valves, the leaks mean the corrosion and worn system. Also, the sealing parts are worn and torn. You need to replace it with a new application.

- Freezing: If you see freezing water inside the irrigation system, the drain valve is not working well. Because it could not drain the water inside the system. So, it is very important to change it with a new one.

- Rust and corrosion: In general, valve applications are made from brass which is very resistant to corrosion and rust if you use it with water. But after a certain time, you may see corrosion and rust.

- Do not work: When you shut off the valve, the water continues to flow. It is a very problematic issue. Because the valve system does not make its duty. This is probably a broken or worn internal ball or butterfly system. The only solution is to change with a new application.

- Difficult operation: In general, operators are turning the stop and waster valve applications with a help of a T handle. Because they are generally installed below the ground. Once you attach the T handle and if it is very hard to turn and open or close, this means there can be a worn or corroded valve system. You need to change it with a new application.

So as you see above, the general solution is to change the stop and waste valve with a new application.

How to Choose a Stop and Waste Valve?

If you need to choose a valve application to change or install to the irrigation or outdoor plumbing system, there are different kinds of things that you need to consider. If you make these considerations well, selecting a system will be very easy for you.

- Size: The most important thing to know. The inlet and outlet sizes of the valve must fit with the piping system. You need to choose the internal diameter of the valve inlet and outlet compatible with the outlet diameter of the piping system.

- Material: There are brass, PVC and stainless steel materials are available for the stop and waste valve applications. In most cases, you use them in outdoor applications. So you need to choose a material that can withstand corrosion such as PVC and brass.

- Pressure: In which pressure that your piping system operates in a maximum way? You need to know the maximum operating pressure of your piping system. And you need to choose a system that can operate in a maximum pressure valve. Check the available maximum pressure rating of the valve system.

- Connection type: There are different connection types available such as soldered or threaded connections. Choose the correct one.

- Temperature: The temperature range is also very important. You need to know in which temperature range you will use the stop and waste valve. So, choosing the correct temperature range is very important and the system must withstand these temperatures.

- Price: Also the price is very important. You need to check the different prices available. And you should know your requirements and you do not need to pay much money for extra features. High prices do not mean high quality every time. But you can be sure that if a stop and waste valve application is a low price, it is low in quality.

Replacement Tips for Stop and Waste Valve

Also, we can give you some replacement tips about the stop and waste valve application.

- First of all, you need to close the water from the main vane to prevent water waste.

- Find the place of the valve if it is placed below the ground. In general, they placed small boxes on the ground.

- Once you find the old valve, you can use a pipe cutter to remove the old valve. The connections are probably permanent.

- Once you cut the pipes, you need to use MIP adapters to extend the valve to the cut sections. They are very basic systems that have both internal and external threads to attach to the valve application. To both sides, attach these MIP adapters to the new valve.

- Install the new valve to its place with soldering or threading.

- Test the valve by opening the water supply from the main vane. If it works properly and if there are no leaks, the operation is successful!

Conclusion

So, you learned all the important information about the stop and waste valve applications. They are very easy systems and if you need to replace them, you need to make the considerations well.

If you have additional comments and questions about these systems, please leave them below. Your precious feedbacks are very important to us!

Related topics about plumbing and valves;

Drain Valve – What is It? Important Things to Know

Air Compressor Check Valve – Guide with All Info You Need

Capped Valve- A Useful Solution to Fluid Flow Systems

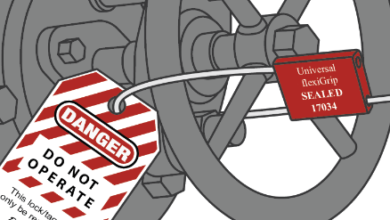

Car Seal Guide – How to Use? What Does it Mean?

Heater Control Valve – What is It? How it Works?

Idle Control Valve – Everything You Need to Know!

Exhaust Valve – Problems, Types and Solutions

SharkBite Shut Off Valve – Detailed and Unbiased Review

Pressure Washer Unloader Valve – All the Points You Need to Know