Pressure Washer Unloader Valve – All the Points You Need to Know

Pressure washer applications are very common in different kinds of places. They provide high-pressure water and detergents to clean the different surfaces. Also, these pressure washers are using an unloader valve system. If you want to get to know about pressure washer unloader valve applications, you are at the right place. You can learn all the aspects about them.

What is Pressure Washer Unloader Valve?

A pressure washer unloader valve is a very simple valve system that the pressure washer systems have. You can understand that the water comes to the nozzle at very high pressure. When you pull the trigger, the high-pressure water is squeezed to the surface that you want.

But when you release the trigger, the high-pressure water stays inside the system. And there is a motor that pressurizes the water constantly. This increasing pressure can be harmful to the system. So, the unloader valves move in this situation. The pressure washer unloader valve must release this high-pressure build-up before the nozzle to prevent harmful things.

How Does It Work?

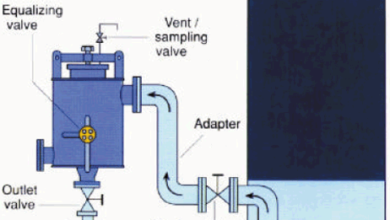

Also, their working principle of them is very simple. The location of the pressure washer unloader valve is right before the nozzle. It has a ball and spring system that exerts pressure on the hole that high-pressure water goes back to the tank from the system.

When you release the trigger, the increasing pressure inside the system opens the ball and spring system and goes back to the low-pressure tank. So the unloader valve application act as a relief valve.

What are the Benefits?

There are different kinds of benefits of pressure washer unloader valve applications. Around these benefits;

- They provide safety for the user. While you are cleaning something with a pressure washer, you will not hold the trigger all time. Sometimes, you need to release it. In this case, the pressure washer unloader valve moves in and prevents the high-pressure build-up in the system. And this prevents any accidents that may take place because of the high pressures.

- Also, you will avoid damage with the use of an unloader valve. After a pressure value, the pressure can cause damage to the system. And these damages can be very costly in general.

- It provides convenience. Because you can easily adjust the pressure that comes to your hose.

Also, you need to be aware of some points about these systems;

- It is very important to adjust the pressure control. If the pressure is very low, you can not cultivate the effectiveness that you need from a valve application. So, you need to make the pressure adjustment very well.

- Heat buildup can be a problematic issue that you need to consider about these systems. Because if you leave the trigger and stay in that position for a long time, the temperature of the water will increase because of the friction and the pressure change. This can harm the other parts of the system that you have.

Common Problems and Solutions with Unloader Valves

Also, you may have different problems with the unloader valve systems that you have. Here you can find the general troubleshoots for the problems that arise.

The Cycle is not Stopping

In general, when you pull the trigger of the pressure washer application, the unloader valve needs to stop working to prevent pressure decrease. But in some cases, it will not close and the bay-passing of the high-pressure water can continue.

- The cause of this problem is the restricted nozzle. When the nozzle is too small, the system can not discharge the high pressure before the nozzle. Because of this, the unloader valve application stays open. You just need to select a bigger nozzle or remove the restriction or debris that prevents the water discharge from the nozzle.

Pressurizing Problems with the System

Another common problem that you may have is the pressure of the water. The pressure is not raised to the optimum value that you intended. Instead of the pressure washer unloader valve, there can be other possible causes of this problem.

- The first cause of this problem is if the nozzle discharge is too large. If it is too large, the discharge of water will be higher than intended. In this case, the pressure can not build up in the system. You just need to replace the nozzle with a normal application.

- Problems with the pump parts can be the reason for the problem. This is whole another story to deal with. Because, the problem can be the pump sealing parts, pump valves, pump motors, or pump wings. You need to inspect the problem much bigger extent which is beyond the topic of this article.

- Another cause of this problem is the worn or torn unloader valve. You need to check the valve system if it is working properly after the nozzle change. Replacement will solve the problem that you have in most cases.

Very High Pressure

Also, you may see very high pressure in the pressure washer system. This can cause very bad problems and damage to the system. There can be different reasons.

- The first reason is the unloader valve is not correctly adjusted. As we stated above, you need to make the adjustments to the unloader valve correctly if you want to deal with the problem. At a specific pressure build-up, the unloader valve must be open to prevent the pressure build-up.

- If less than 5% flow goes back into the bypass system, the pressure buildup can be a problematic issue. You may have problems with the very stiff unloader valve. Valve adjustment would solve your problem.

By-Pass Do Not Take Place and Motor Stall Happen

This is another scenario that would take place if there is a problem with the unloader valve application that you have. If the bypass does not take place, the increasing pressure can harm the system that you have. And also stall may take place in your engine.

- There can be foreign materials in the system that prevents the unloader valve works properly. You need to clean the system and check for other contaminants and debris.

- Also if there is a recess of water in the pump system, the pump system can not pressurize the system because of the air bubbles. You need to be sure that you provide enough amount of water.

- There can be leaks in the system.

Adjustment of Pressure Unloader Valve

If you understand the general working principle of these systems, you can also understand how to adjust them correctly.

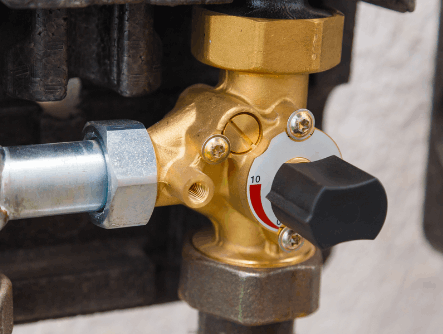

You know that there is a spring that holds the ball system in place in these applications. If you increase the stiffness of the spring, the unloader valve will release the system at higher pressures. Because to open the ball, more water pressure will be required in general.

- To adjust the stiffness spring, there is an adjustment bolt or knob. Once you rotate it, you adjust the stiffness of the spring.

- What you need to do is, just operate the water pump. And measure the pressure once you pull the trigger of the wand. This is the working pressure.

- And, release the trigger and turn the knob or nut clockwise to make the spring stiffer to increase the pressure. And then, push the trigger and check the pressure.

- Repeat this cycle to reach the intended working pressure that you need.

This is the general principle that you need to apply if you want to adjust the working pressure of your system.

Conclusion on Pressure Washer Unloader Valve Systems

These are the general things that we can explain about the pressure washer unloader valve applications. They are very basic systems and if you understand the general working principles of these systems, it will be much easier to deal with these applications.

If you have additional comments and questions about these systems, please leave them below. Your precious feedbacks are very important to us!

Check the related topics about the valves;

Air Compressor Check Valve – Guide with All Info You Need

Capped Valve- A Useful Solution to Fluid Flow Systems

Car Seal Guide – How to Use? What Does it Mean?

Heater Control Valve – What is It? How it Works?

Idle Control Valve – Everything You Need to Know!