Oil Filter Cutter – Usage, Types and Buying Guide

Oil filter cutter applications are very useful applications that we use in automotive systems. By using the oil filter cutters we can cut the oil filters through their cases to reach their internal structure. Here you can find detailed information about the oil f, filter cutter applications.

What is Oil Filter Cutter?

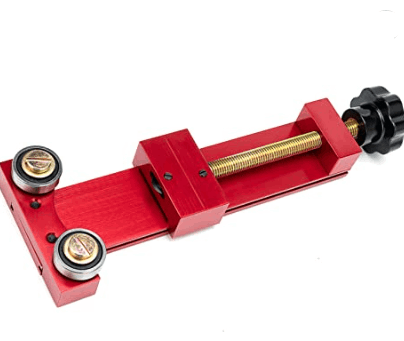

As we stated above, oil filter cutter systems are very basic systems that have a rectangular shape. And there is a blade attached to this rectangular body to cut the oil filters in half.

You know that oil filters have different parts inside their structure. And the most important part is the filer itself that oil goes through it. To reach this filter, you need to cut the external casing with an oil filter cutter.

Why Use Oil Filter Cutter?

The most important reason that we use the oil filter cutter applications is to cut the system in half to see the condition of the oil filter. By examining the general particles and the situation of the oil filth inside the filter, you can understand and make diagnoses about automotive engines.

Also if you’re suspicious about the oil filter system of a passenger car, you can cut the oil filter system in half to look at the internal structure. And you can make different examinations in the structure of the filter.

Also without cutting the oil filter, you can not understand that there is a problem with the filter. If the filter is clogged or filthy, you can only understand it by cutting.

Who Uses Oil Filter Cutters?

Different people from different professions are using oil filter cutter applications in general.

- Mechanics: As you can guess that the most common users of oil filter cutters are mechanics in general. Because they are examining the oil filter system of different passenger cars. And they are professionally dealing with this thing.

- Engine enthusiasts: If you are an engine enthusiast, you can buy an oil filter cutter for yourself. You can easily examine the oil filter of your car to see if there is a problem with them.

- Oil filter sellers: There are also special places that they are specialized in the oil filters and oil systems of different vehicles. So, they are generally very good at dealing with oil filters.

So, if you are inside one of these groups, you will probably need an oil filter cutter application. Here you can find the general information that you need.

Parameters to Consider While Buying Oil Filter Cutters

There are different kinds of parameters that you need to consider if you want to buy oil filter cutter applications. If you make these considerations well, it will be very easy for you to choose the best oil filter cutter application for yourself.

- Size: This is the first thing that you need to consider about the oil filter cutter applications. There are different sizes of them in the market that you can buy. These sizes are generally for different kinds of applications. And yoıu know that there are different sizes of oil filter applications available in the market. And you need to be sure that the size of the oil filter cutter is compliant with the general oil filter sizes that you are dealing with. Also, you do not need to pay much money for bigger applications if you do not need them.

- Construction: Also durability is very important. There are different cutters are made from different kinds of materials. So, it is very important to choose a durable construction that is made from durable materials such as stainless steel.

- Price: You need to define a strict budget for yourself to use the oil filter cutter applications. If you know the maximum money that you an spend, selecting the best application will be very easy for you.

So, you need to know the general needs and your general expectations from a cutter. And you do not need to pay extra money for the extra features in general.

What are the Different Types?

Also, there are different constructions and applications of oil filter cutter systems available in the market. You need to choose the best application according to your needs.

- Pneumatic cutters: Pneumatic cutters are automated applications that us ethe pneumatic power. They apply excessive force to cut the oil filters easily. So, they are very useful systems if you are looking for an easy-to-use application. And they are suitable for heavy-duty systems.

- Hydraulic cutters: Hydraulic oil filter cutter applications are also the same as pneumatic systems. You can use them in heavy-duty applications without any problem.

- Electrical cutters: They are mechanical systems that actuated with the help of an electrical engine. You just need to monitor the working of the machine if you want to cut the oil filters.

- Adjustable systems: These systems are adjusted according to the sizes of the oil filters. If you want to cut them with these applications, it is very easy to apply in general. And versatility is way higher than the normal oil filter applications.

- Handheld applications: These types of cutters are the most common types that you can find in different kinds of workshops. You need to use your force to cut the oil filter. You just need to apply a specific amount of power to the leverage system to cut the encase of the system. In terms of price, they are the cheapest applications in general.

Recommended Oil Filter Cutter Products

Below, you can find different products that you can check and compare to understand the general prices and the market. These products are selected to show the different features and different types of applications that you can buy. While you are choosing an application, always consider the things that we stated above.

Qagea 66490 Oil Filter Cutter

As we stated above, the most common systems are handheld or mechanical oil filter cutter systems. This one is one of the most common constructions that you can find in different workshops.

There is a swivel mechanism that you can turn to adjust the clearance of the wise with a help of a screw mechanism. You doı not need to apply so much force to break even the hardest oil filter case materials.

- It has a cutting range of 1-3/4″ to 5-3/4″ sizes of oil filters which is compatible with most passenger car filters.

- High-quality aluminum casing and high-quality anodized blade material provide high-quality material.

- ISO-certified quality.

- Comes with 2 years of warranty.

| Pros |

| – Easy to use system. – Compatible with most standard oil filters. – Comparatively cheaper application. |

| Cons |

| – Can be slow for serial cutting applications. |

Oil Filter Cutting Replace Tool

This one is another oil filter-cutting tool. One of the most common applications is that it is used for up to 5 ½ inches of applications.

In general, it has the same properties and features as the previous one.

Also, you can check the other products from that page to find the best one for you.

How to Use Them?

Also, it is very important to use the oil filter cutter applications properly.

- First of all, it is a dangerous process. Because you apply load to break a casing. And there can be parts burst from the system and harm you. So, you need to take important safety precautions. Wear your cut-resistant gloves, safety barret, and safety glasses while dealing with oil filter cutters.

- Place the oil filter vertically in the bed of the cutter as you see in the photo.

- Start to rotate the screw in a clockwise way to make the wise narrow. You need to apply it carefully and slowly to prevent accidents. Up to you to hear the cracking sounds of the casing, and continue to rotate.

- Once the casing cracks, stop rotating and rotate counterclockwise to make the system lose. And take the oil filter.

- Clean the bed after removing the oil filter.

Conclusion

These are the general things that you can consider while you are buying oil filter cutters. And it will be very easy to you to choose the best application for yourself if you make the general considerations well.

If you have additional comments and questions about this topic, please leave them below!

Check the related content about the engine oil;

Oil Filter Housing – What is That? Complete Guide

Oil Filter Removal Tool – Selection Guide with Products

Check Engine Oil – Hot or Cold? What is the Proper Way?

Change Engine Oil Soon Warning Light – What to Do?

Check Engine Light After Oil Change – General Causes and Fixes