Elevator Pulley – How Does It Work?

Elevators are very important parts of human civilization. And they’re very high-rise buildings in crowded cities. Thanks to the elevators, we do not need to climb all the stairs to get to 35. floor o the buildings. Elevator systems have lots of parts and sub-systems that they make it easy to carry heavy objects to higher elevations. One of these sub-systems is the elevator pulley system. Here we will explain how these systems work and other insightful information about them.

What is the Elevator Pulley?

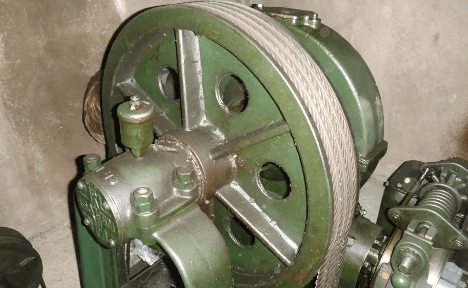

The elevator pulley is a part that all the elevators consist of inside them. They are the systems that carry heavy objects from the ground. A high-strength metal wire goes around them. And at the two sides of this pulley, there are weights. One side has the elevator cabin that is full of people, and on the other side, there is a counterweight that weighs nearly the same as the cabin loaded with people.

So, we can say that elevators are nearly the same weight balance on either side. Counterweight makes it easy to carry the people and elevator cabin to the higher floor. With the increasing number of people or objects inside the cabin that exceeds the counterweight weight, more power is needed to pull the elevator with a pulley.

So, these systems are the systems that carry lots of weight on them. Because of that, they are very important systems that they must be designed very sturdy to withstand such forces.

Force on Elevator Pulley

The forces on these systems are two-sided. They are ca<zrrying both the counterweight and the elevator cabin with the load. These two forces are acting downward with the metal high-strength ropes. And the elevator pulley is liked by an axle that carries the pulley itself. This means that the axle takes all the load as a bending moment.

Elevator Pulley Axle

Also, engineers must design axles with very high mechanical strength. Because they are the systems that take nearly all the load of the elevator system. And they are embedded in the building structure to rotate their axle.

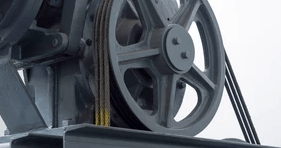

What Rotates the Elevator Pulley?

With the rotation of them, the elevator system works and carries the people between the floors. There is an electric motor that rotates the elevator pulleys with the action of gears f other timing pulleys. So, the main power comes from the electric motor of them.

Thanks to the counterweight of the elevators, there is no need for a lot of electric power to carry the elevator cabin between different floors.

How Does Elevator Know the Different Floors?

The adjustment of the different floors is a very important thing. There are must specific rotations that the elevator pulley must make to achieve the different floor levels that the elevator cabin takes.

This is made with a software system embedded inside the control system of the elevator. When people pushing to the floor buttons in the elevator cabin, the cabin sends a signal to the controller of the elevator. The controller calculates how much rotation and which direction of rotation is needed to take that floor. And the relays are giving signals to rotate the electric motor and this system in this rotation and direction.

Types of Elevator Pulley Systems in Different Manufacturers

With the changing size and capacity of the elevator systems, there are different kinds of elevator pulley systems are available from different manufacturers. Also, you can find high-technology systems from different manufacturers.

- Tackle Pulleys: These are the elevator pulley systems that we are using in most little elevator applications. They are plastic pulleys that directly transmit the rotation o the electric motor to carry the system.

- Deflection Pulley: These are the types of systems that enable the direction change of the rope system of the elevator.

- Hydraulic Pulleys: There are also hydraulic elevator systems available in different applications. These are the plastic pulleys that directly receive power from the hydraulic movement system.

- Cast Iron Pulleys: Also, these are the types of pulleys that directly receives power from the electric motor in big elevator systems. Most of the passenger elevators in different sizes have cast iron pulley systems in general.

How Must Be the Elevator Pulley Systems?

While you are designing and selecting one of them, you need to take care of these points about them;

- They must work silently and vibration free. Because comfort is very important in elevator systems. And if we think the so much load in the elevator pulley system, you need to select or design a pulley that works silently and vibration-free in these conditions.

- The material must be high quality and high in strength. You are designing a system that carries humans inside it. So the safety precautions must be highest.

- Must be according to standards. You need to have an elevator system that is designed according to the safety standards that you can easily make for the different kinds of applications in general.

- The corrosion resistance of the material that you are using for the elevator pulley is very important. You need to have a very good elevator pulley system that is designed to withstand these corrosive media.

- The bearing systems that will carry the elevator pulley systems must be very good in terms of materials. So, you need to have a very good material that will carry such a load.

Last Words

As you see above, there are different kinds of important points that you need to know about the elevator pulley systems that you need to know about.

If you have further questions about this topic, leave your comments below!

Related contents;

Driveshaft Loop Mechanisms – Everything to Know

Is Aftermarket Catalytic Converter Loud? OEM and Mufflers