Capped Valve- A Useful Solution to Fluid Flow Systems

In hydraulic and pneumatic applications, we are using different kinds of valves. And one of these valves is the capped valve application. Here we talk about the capped valve systems that we use in different applications. You will learn about which system we use and other important topics about them.

What is Capped Valve?

As you understand from its name, these valves have a cap or cover that is made from plastic material. And we can adjust the flow direction o the fluid with that cap. These caps prevent any leaks from the valve system. So, they are very important for different kinds of applications.

What Are the Benefits of Capped Valve Systems?

There are different kinds of benefits of these systems.

- The most important feature of these systems is the safety that they are providing. They prevent pressure build-up in the pipe system. And also they prevent hazardous gases that can leak.

- Also, capped valve applications have very low maintenance needs. This is because they have very basic systems in general. This low requirement of maintenance needs prevents extra costs. So this makes them cost-effective.

- They can regulşate the pressure of the flowing fluid inside the pipe.

- In general, they are made from high-quality materials that will prevent corrosion. Also, they prevent liquids or other particles run into the system.

Types of Capped Valve Applications

According to the working mechanisms, there are different capped vale systems available that you can use in different kinds of applications.

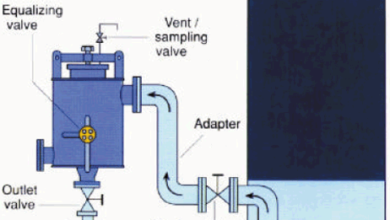

- Globe valve: In these systems, there is a cap that is attached to a stem or disc. When you rotate this cap, teh disc or stem opens or closes to regulate the fluid flow inside a pipe.

- Ball valves: Ball valve applications are generally very common in the fluid regulation of oil and gas systems. The cap is attached to a ball that can rotate inside the valve. When you rotate it, the ball prevents or allows the fluid flow inside the valve system.

- Butterfly valves: Butterfly valves have a disc system that a cap is attached to it. When you rıtate the cap the disc inside the pipe system rotates. The dis allows or prevents the fluid flow. The working principle of the butterfly valves is nearly the same as the globe valve applications.

- Check valve: Check valve applications generally allows the fluid to flow in only one direction. When the fluid flow comes from the correct direction, the mechanism of the check valve allows the flow. But when the fluid flow comes from the other side of the flow direction, the valve closes.

- Plug valves: The use of plug valves are very common. There is a plug mechanism that the cap is directly attached to that. And when the cap is rıtated, the plug system turns and allows or prevents the fluid flow inside it.

Which Applications Do We Use teh Capped Valves?

- Plumbing: This is the most common use of teh capped vaşve systems in general. We can easily control the fluid flow between teh sinks and faucets with the capped valve applications.

- HVAC: You know that fluid control in HVAC applications is a very important thing that we need to do. So, we are using teh capped valve applications to control the fluid flow between the sub-systems.

- Industrial uses: The control of the different fluids such as gases, oil, and other materials, the use of the capped valve applications common.

- Medical: We use closed valve systems in the oxygen tanks and respirators to control the flow of the gases.

- Automotive: We use teh capped valve applications to control the brake fluid, oil, and fuel flow in the systems.

So they are generally versatile and universal applications that we can see in different kişnds of areas.

Considerations While Selecting the Capped Valve Applications

As an engineer or technician, you can find yourself selecting a proper capped valve application for a system. If you consider these points about them, you will be able to select the correct system for yourself.

- Size: The inlet and outlet sizes must be compatible with the pipes and hoses that you will connect with them. Also, you need to consider the connection type of these valves.

- Material: You need to select a corrosion-resistant fluid to prevent the corrosion can take place because of teh fluid type that you’re using. In these cases, teh valves are generally made from cast iron, and the internal structures are generally made from plastic or steel. Also, brass material is very common.

- Temperature range: At which temperature you will use teh capped valve applications? Always consider the temperature range of the capped valve application that you are using in general.

- Actuation: There are capped valve applications available as pneumatic, hydraulic or electrical. Choose the best system for your application.

- Certification: Which certifications that tşs valve meets? And which certifications that you need for that value application? You need to know the general certifications that you need from a valve application and select a proper one. For example, UL and CSA systems are very important for electrical applications.

Important Maintenance Tips for Valves

Also, there are important points that you need to apply while you’re applying maintenance to the capped valve systems.

- First of all, the maintenance must have a regular schedule. So, it is very important to check and make the maintenance in a specific period. And most of the time, there are manufacturers’ instructions to make maintenance to these systems.

- And you need to clean the dirt accumulation that can cause and prevent the normal working condition on the valves.

- Lubrication is also a very important thing to make. You need to regularly lubricate the moving mechanisms of teh capped valves. Lubricate the ball and the lever mechanism and teh cap system on regular basis. This will prevent wear and prolong the life of teh valve applications.

- Replace the worn valve and change them with teh new ones.

- Specify a maintenance plan on a monthly and yearly basis and apply this schedule properly.

What are the Prices?

Teh capped valve applications generally very wide range of products. Different systems are made from different materials, different sizes, and different working conditions.

So it can be very hard to give a specific price for these systems. Think about giving a general range by considering the basic systems for plumbing applications and complex ad heavy-duty systems for steam engines.

It is very important to consult with professional providers and manufacturers and take offers from teh different sources. And then you will be able to have a general insight into the capped valve applications.

Conclusion

Here, we tried to the insight into teh capped valve systems from teh different aspects of the topic. And you know their general working principle, types, applications, and important points to consider.

Upon them, if you have any additional comments and questions about this topic, please leave them below.

Check the related topics about valves;

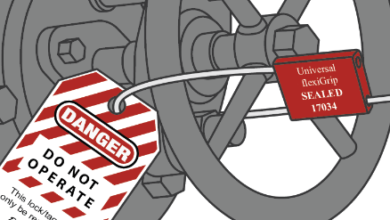

Car Seal Guide – How to Use? What Does it Mean?

Ball Check Valve System – Applications and Problem Solutions