Air Compressor Check Valve – Guide with All Info You Need

Air compressors are very important systems that we use in modern engineering applications. They provide compressed and high-pressure air to us. And also the use of check valve systems in these compressors is very common. Here, you can find detailed information about the air compressor check valve systems.

What is Air Compressor Check Valve?

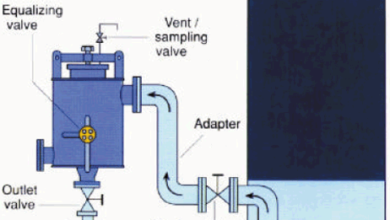

In essence, the check valve applications are the valve systems that allow the fluid to flow in one direction only. For example, if you install a check valve to a fluid flow system, you allow the fluid to flow in only one direction. So, they prevent the backflows in these systems.

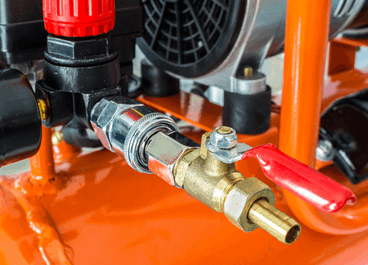

So, the use of air compressor check valve applications is very common in air compressors. To compress the air, we need to provide air inside a tank. And we need to prevent the air escape from this tank. To do it, we use air compressor check valve applications.

How Does it Work?

The working principle of these valves is very simple. There is a plug or ball system that closes the hole where air flow takes place inside the valve. And this ball is connected to a spring. Spring applies a little force to close the hole with the ball. When there is an airflow from the hole to the ball, the ball pushes the weak spring and allows the air to flow inside the system. But if there is airflow from another side, the spring and ball system do not allow the air to go through the hole. Because the pressure of the spring and the incoming air to the ball makes the ball closes the hole tight way. This prevents air to escape.

So, if we take a look at the structure of the air compressors, we see that the use of check valve applications is very common. Because we can increase the air pressure inside the tank by applying more air through the check valve. But the check valve mechanism prevents the air leak from the tank.

Important Points to Know about Them

If you are looking for air compressor check valve applications, these are the general things that you need to consider. If you make these considerations well, you will not have any kinds of problems while selecting these applications.

- Size: The size of the check valve is very important. Probably there will be hose connections to the tank of the air compressor. And in this tank, there is high-pressure air. You need to be sure that the inlet and outlet diameters of the check valve are compatible with the air compressor.

- Material: There are different materials available. But the most common applications are brass and stainless steel materials. If valves are made from these materials, they are probably the highest quality materials.

- Maximum pressure: Also the maximum pressure of the air compressor system is very important. For example, if the maximum air pressure storage in the tank is 200 PSI, you need to look for systems that are a minimum of 200 PSI strength.

- Temperature: Also the temperature of the flowing air is very important. Most air compressor applications are operated at room temperature. But if you are using hot air, you need to check the general applications that are durable at these high temperatures.

- Type: There are different check valve types available. You need to know the previous or old check valve type to choose the best application for yourself.

- Price: You need to take offers from different sources and different sellers. And you need to choose the best application for yourself.

Types of Air Compressor Check Valve Applications

There are different types of air compressor check valve applications are available. You need to know which kind of valve is used in the air compressor application that you have. So, selecting the proper valve will be very easy for you.

- Ball check valve: This is the most common check valve application used in conventional air compressor applications. This is the ball-spring system that we explained above.

- Diaphragm check valve: Instead of a ball, there is a flexible diaphragm application that closes the air passage. The diaphragm system is connected with a spring and piston application. When air pressure drops to a certain degree, the spring and piston system forces the diaphragm the close the air inlet.

- Swing check valve: Instead of a diaphragm, there is a flap that swings with a spring system.

- Piston check valve: There is a basic piston system that operated with a spring system. When the pressure drops, the piston is forced to seal the opening with a spring system.

The general working principles are the same with them. And choosing the correct application is very important for your system.

Bad Air Compressor Check Valve Symptoms

Also, it is very important to know if there is a problem with the air compressor check valve system. And you can apply the remedy according to the problem.

- Pressure loss and air leak: This is the most common symptom that you will see in a check valve application. Because the machine does not work properly and this causes air leaks.

- Frequent compressor cycles: In some automated systems, there is an electric motor that operates the compressor to increase the air pressure inside the tank. Below a specific pressure, the compressor starts to work. So, if there is a leak in the check valve application, the compressor will work more frequently. Because the pressure inside the tank drops every time.

- Noises: While the compressor operates, you will hear tickling noises coming from the valve because of the worn elements inside the system.

- Hard pressure build-up: It will take a specific time to build the required pressure inside the compressor system. But if there is an air leak from the system, increasing the pressure will be very hard for the machine.

So, if you have these symptoms, you need to change or repair the valve.

How to Change an Air Compressor Check Valve?

First of all, you need to be familiar with the general mechanics. And you need to know the general elements that your air compressor system has.

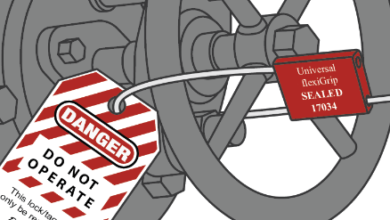

- You need to unplug the air compressor from the electricity. Dealing with electrical machines while they are connected to electricity is a very dangerous thing.

- Your machine probably has a drain valve. You need to drain the air inside the tank. Release the drain valve and drain the air.

- The location of the check valve is generally near the tank. And it is connected to the pressure switch and the compressor head. You need to disconnect these switches and the head. And then remove the old check valve from the compressor.

- And then, install the new check valve to the air compressor.

- Close the drain valve.

- Operate the air compressor and see if there is a problem.

How are the Prices?

It is very hard to give a piece of information about the exact prices. Because different parameters affect the prices in general. The brand, sizes, and features affect the prices in general.

But if you are looking for a basic air compressor system in your home, a typical ball check valve will cost around $15-$30. They are not generally high price applications. Also if you are considerate about the brand and the quality, you can find valves have higher prices up to $100.

Conclusion

These are the general things to consider about air compressor check valve applications. So, you know all the general aspects that will help you in different situations.

If you have additional comments and questions, please leave them below.

You can find additional content about the valves;

Capped Valve- A Useful Solution to Fluid Flow Systems

Car Seal Guide – How to Use? What Does it Mean?

Heater Control Valve – What is It? How it Works?

Idle Control Valve – Everything You Need to Know!