3 Way Ball Valves – Types, Definitions

Valves are the most common components in mechanical systems such as hydraulics. They are controlling the fluid flows in general. There are different types of valves. One of these valves is the 3 way ball valve. Here you can find detailed information about the 3 way ball valves. Also, you can find information about the selection guide for these systems.

What is a 3 Way Ball Valve?

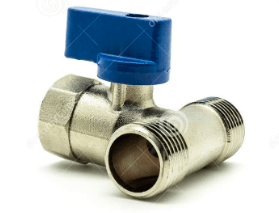

3 way ball valve is one of the most common pieces of equipment in hydraulic and piping systems. As you understand from its name, there is a three way connection point for these valves. And you can control the flow of fluid between these three way connection points. So, this makes them very useful in different engineering applications.

If we take a look at the working principle of the 3 way ball valves, there is a ball-like structure that has an openness at one side. With the valşve arm, you are adjusting the direction of this openness. And according to the direction, you can adjust the direction of the fluid flow between the three ports. And the closed side closes the other port to the fluid flow.

There are various kinds of constructions and energy systems available for the 3 way ball valves in general.

Advantages of 3 Way Ball Valves

There are different kinds of advantages to the 3 way ball valves are in general.

- They are very useful in the switching thew flow between 2 directioıns. This provides very good versatility in complex fluid flow systems. So controlling the fluid flow in the complete engineering systems, the use of the 3 way ball valves is very common in general.

- Some of the types provide very good control of the fluid flow; let the fluid flow between two inlets and not letting fluid from the third inlet.

- You can easily divert the fluid flow between the different directions in general.

- You can also shut the fluid flow from three directions to completely halt the fluid flow.

Disadvantages of the 3 Way Ball Valves

There are also some kinds of disadvantages to these valves are.

- Cloggings can be a problematic issue in the 3 way ball valves in general. Because there is a connection of three ports on one side. So, in the connection section, there can be cloggings if the flowing fluid is not pure.

- Also, wear is a very important problem for the 3 way ball valves. The wear of the ball valve takes place because of the constant fluid flow. The ball of the valve gets dull over time and the fluid flow willş start to mix in an unintended way.

- Dissembling the 3 way ball valves can also be problematic. Because disassembling the three ports at the same time can be impossible. You need to dismantle the pipes first to dismantle the 3 way ball valves.

Types of 3 Way Ball Valves

According to the type of application, there are different types of 3 way ball valves available. The general types are;

- L-Port valve

- T-port valve

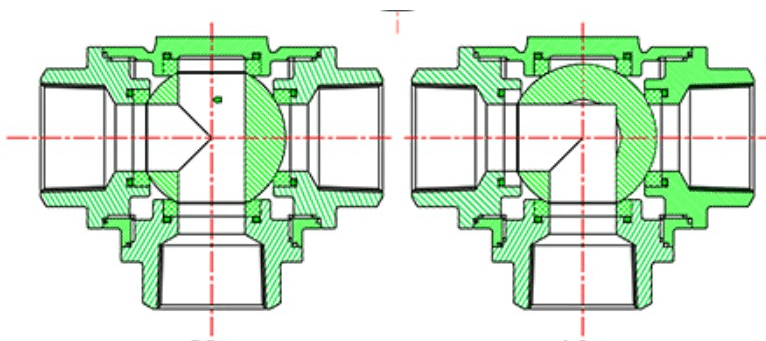

T-Port Type

This is the first type of the 3 way ball valve. And also, they are the most common ones in general. So, t-port valves are very important for fluid mixing applications that come from two different ports in general. And these two sources of fluids are mixed and go through the third port.

And also, you can direct the fluid flow between the different ports in general. So, it will be very easy to direct the fluid flow between the ports with the T-port type.

The most important disadvantage of the t-port type, you can not completely shut all the ports at the same time. You need to have an additional valve to stop all the fluid flow that takes place in the T-port type.

While using the T-port type of 3 way ball valves, you need to be sure about the heads of the mixing flows must be consistent with each other. Otherwise, the fluid flow will not take place properly. And the flow with higher pressure or head will prevent the other fluid that flows inside the chamber.

L-Port Type

This is the second type of them in general. The most important difference between the L-port type, you can adjust the fluid flow between 3 different ports. But you can not make fluid mixing action like the T-port type makes.

The advantage of the L-port type is, you can easily close all the fluid flow from the three different ports at the same time. And you do not need to use an extra valve to stop the extra fluid flow in general.

L-Port or T-port?

There are various kinds of advantages and disadvantages of the L-port 3 way ball valves and the T-port ones.

- T-port valves allow the fluid flow between the ports that are in the same orientation while closing the other diverting direction.

- L-port valves are best for directing the fluid between the diverted ports.

- T-port valves can not close all the inlets at the same time but L-port types can.

- L-port types do not allow the mixed fluid flow in 3 way chambers but T-port does.

So while you are selecting L-port or T-port 3 way ball valves, you need to be aware of these advantages and disadvantages of them.

Understanding the Type of 3 Way Valves

Also, the operator needs to understand which kind of valve they are using. And how to adjust them to direct the fluid flow in a specific direction.

As you see above, there are generally markings on them like above. You can understand from this mark which direction you are directing the flow.

The directions of the arrows show the directions of the fluid flows in general. So, you can easily understand which direction the fluid flows.

Manual and Electric 3 Way Ball Valves

This is also a very important criterion while you are selecting the 3 way ball valves in general. Some of the valves are electric and automated some of the valves are manual or hand-operated. According to the type of operation, you can use one of these.

Electromechanic 3 Way Ball Valves

The valve action takes place with the action of the electric solenoid. And the command comes from the CPU of the controller. In general, these kinds of valves are very common in automated hydraulic systems. Once the operator pushes a button, the computer sends a signal to the solenoid, and the selenoid adjusts the position of the 3 way ball valve according to this signal.

Manual Valves

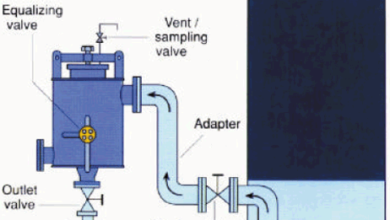

In most, sewage and piping applications, manual valves are common in practice. Control of the fittings and drainage is very common with manual valves in general. The general use of manual ones is generally like this.

Conclusion on 3 Way Ball Valves

As you see above, there are generally two types of 3 way ball valves. You need to know the general differences between these types to select a proper one for your project.

Furthermore, there are electromechanical and manually operated valves available in the market. According to the use area, you can select the best one for your application.

Also, consider the advantages and disadvantages of these valves in fluid flow systems in general. It is a very important point while you are selecting the proper valve application.

These are the general points that we can explain to you. Finally, do not forget to leave your comments and questions below about the 3 way ball valves. Your precious feedbacks are very important to us.

FAQs

The working principle of the 3 way ball valve is, there is a rotating metal ball between the ports. And there is a space on that ball that allows the fluid flow from these ports. According to the placement of the ball, you can easily adjust the flow direction of the fluid from these three different ports.

2 way valves generally allow the fluid flow between the two ports. ON or OFF. But in the 3 way ball valve applications, you can adjust the flow direction of the fluid flow between the three ports. And you can direct the fluid flow between the 3 different ways with these valves. This is the general difference between the 2 way and 3 way valves in general.

The most common application of the 3 way valves is generally the hydraulic and fitting applications. In hydraulic applications, electronic solenoid valves are much more common. And also, manual valves are common in the sewing and water fittings in general. If there is a flow in complex engineering systems, the 3 way valves are very common in general.