Valve Lapping – What is It? When to Apply?

To improve the engine performance, sometimes very basic applications are applied such as valve lapping applications. Here you can find detailed information about the valve lapping applications that are very common in automotive.

What is Valve Lapping?

Valve lapping is a fine grinding process that we apply to valve edges and valve slots. By using a fine tool, we create a very good surface between the seating surfaces. So, it is a very important process that we apply to the exhaust and intake valves.

You know that exhaust and intake valves control the income and exhaust of the air-fuel mixture and exhaust gases from the cylinder. So, the most important thing is to prevent any leakages from the valves to the outside. This will decrease the engine performance badly.

So with the application of valve lapping, we increase the surface characteristic of the contacting surfaces of the valve and the valve seat to prevent any leakages. And it will be possible to deal with the problems.

When to Apply Valve Lapping?

As you know that if there is big damage to the engine valves, you need to replace them with new applications. So valve lapping is not generally the exact solution for the problems with engine valves.

If the engine performance reduces because of the slight leaks on the valves, valve lapping can be a solution. And also, if there is a problem with the engine compression, this can be caused by the worn valves and valve seats. Valve lapping can be a solution also in this case.

If you do not apply valve lapping, misfires, and rough idle can be problematic issues. Also if the problem with the valves and valve seats, you will feel it as a very big engine performance reduction. So, it is very important to deal with the problem properly.

How is the Valve Lapping Applied?

First of all, valve lapping is not a DIY thing that you can apply with ordinary tools in your garage. And assessing the situation if you need this process is not an easy task. The professionals must assess if you need that process.

And the application of this process requires special tools and special expertise. But in general, the application processes include these steps;

- First of all, you need to remove the valves from your engine system. This is not an easy task. You need to remove the engine head to reach the valves.

- After removing the valves, you need to clean the valves and valve seats on the engine with brushes and agents to remove the carbon buildup. Before applying the lapping, you need to be sure that the surfaces are clean enough.

- The valve lapping application is applied with a special compound. You need to apply the compound on the surfaces that you want to apply the lapping application.

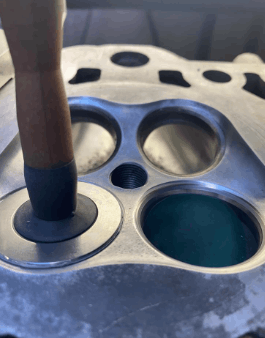

- There are different tools are available in the market. Some of them are manual, and some of them are automatic. You just need to place the tool on the surface and rotate it by pressing it. This will create a good and finished surface on the valves and valve housing.

- You need to check the sealing between the surfaces in a frequent ways. Because you need to avoid over-lapping. And check frequently if the sealing between the valve seats and valves is good.

- After the process finishes, remove the compound and clean the seats and the valve. Dry them thoroughly and make the installation.

- Reassemble the engine and test it if it is working with better performance. Check if it is giving the same sounds.

These are the general things that the valve lapping steps.

Types of Valve Lapping Tools

As we stated above, there are different tools that you can apply this process. If you are a mechanic and are looking for a tool for it, you can consider these applications.

- Hand-held systems: They are very basic systems that you can apply this process. There is a rubber suction cup at the end. You attach this cup to the valve face. By holding the wooden handle, you can apply the lapping process by rotating it. It is generally an inexpensive process to apply.

- Valve lapping sticks: They are the basic sticks that you can attach to a rotating machine such as battery drills. And apply to the valve and the valve seat to apply to the lap. There are different sets that you can apply the lapping application.

- Valve lapping machines: They are special machines to lap the valves on a serial basis. If you need to make the valve lap to multiple applications, you can apply them with a machine. But it requires a skilled operator.

You can choose the most appropriate solution for your system.

General Prices of Valve Lapping

The prices of the valve lapping applications can change according to the brand and the model of your car, the size of the engine, and the required expertise. But in general, these applications are not easy.

First of all, the labor costs are higher than the capital required for the lapping. So, if we think about ordinary passenger cars, prices may change between $500-$1000.

If the valve lapping the valves with new applications will solve the problems in general.

Do New Valves Need to be Lapped?

As we explained above, if you change the valves with new applications, you do not need to lap the valves.

What Grit for Valve Lapping?

This is also a very serious question. You need to choose the best grit to obtain the best surface quality. If the grit is very high, the surface will be rough and you will get the required amount of performance.

Also if the grit is everyone, you can not lap the valve effectively. In most of the applications, the lapping compounds are generally 400 grit.

Conclusion

This is the general information that we can provide to you about the valve lapping. If you have additional comments and questions about this topic, please leave them below. Your precious feedbacks are very important to us!

Check the related topics about the engine valves;

Brake Booster Check Valve – A Complete Guide