Torsion Axle – A Different Suspension Technology

When it comes to suspension technology, different kinds of laws of mechanics and physics are applied in general. One of these applications is the torsion axle system. Here you can find detailed information about the torsion axle systems and their general features.

What is Torsion Axle?

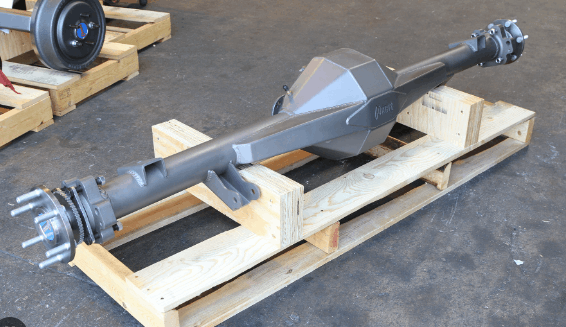

A torsion axle is a system that provides smoother action to the vehicle. There is a rubber material enveloped inside the metal bar. When the wheel is moved up and down because of the obstacles on the ground, the wheel transmits this motion to the torsion axle. The rubber material inside the axle makes the torsion movement to absorb the shocks and forces.

These axles are directly connected to the frame of the car. And the other end is connected to a rod which is connected to the wheel. When the wheel moves, the rod makes the torsion axle rotate around its axis. And the rubber inside the axle dampens the shocks with this effect.

What are the Advantages?

There are several advantages that the torsion axle systems provide to certain vehicles.

- First of all, they provide much better ride quality with better absorbance of the forces and shocks coming from the ground. They are generally better than conventional spring suspensions.

- Each wheel can act independently with the torsion axle system. This provides much better handling to the vehicle.

- They are generally very good for the lowe height vehicle applications. Because, unlike the spring suspension systems, they do not need higher systems.

- Another important advantage that these systems provide is the lighter-weight application. They are much lighter than conventional systems.

- In terms of maintenance costs, they are generally much better than conventional systems. Because they have much more simple applications if we compare them with the other systems.

- The lifespan of these systems is also longer than the usual applications.

What are the Disadvantages?

There are also different kinds of disadvantages that we need to consider about the torsion axle applications.

- First of all their weight-carrying capacity is generally limited. If so much weight is applied to these systems, they will deteriorate or be damaged.

- Once they are damaged, it is very hard to repair in general. You need to replace all the systems.

- Some hard systems can provide rougher suspension systems. The material has a profound effect on the suspension.

- Also, the smoothness of the suspension depends on the stiffness. For the spring suspension systems, you can adjust the stiffness value easily to change the smoothness. But for these systems, the stiffness value is generally constant.

- The use of these applications is not common in all cars in general. So, if you want to apply these applications to your vehicle, it will be hard to find a system.

Use of These Systems

In general, the use of torsion axle systems is common in trailer systems. For lightweight trailer applications, we use them as a common suspension system. For example, in utility trailers, boat trailers, and other kinds of lightweight trailers, the use of suspension systems is very common in general.

In windy environments and environments where vibrations are a common problem, the use of these applications is very common. Because they are very good to absorb the vibrations and jerks coming from the wind in general.

Also at the systems where the ride height is an important parameter, the use of the torsion axle applications is very common.

What are the Common Problems of Torsion Axle Applications?

The most important problem that we see with the torsion axle applications is overloading in general. If they are overloaded, they are easily damaged and must be replaced.

The alignment and the balance for the torsion axle applications are very common problems. You need to find an expert to adjust the required balanced alignment between the systems.

Also, corrosion is a common problem with these systems.

Replacement Prices

It is very hard to give an exact price for the replacement. Because the type of the material and the size of the system have a profound effect on the replacement prices in general. But if we need to give a price range for these applications, $500-$1500 is the general price range for these systems.

Regular inspections and maintenance will save you from these problems in general.

Conclusion on Torsion Axle Systems

As you see above, they are not common applications in automotive systems in general. We need to consider different kinds of things if we want to use them in your system.

What do you think about this system? Are they better? Leave your thoughts on this topic below!

Check the related topics about the suspension and other systems of vehicles;

Torsion Bar Suspension – What is It? What are the Advantages?