Spot welds are a very common joining technique that we are using to join the metal panels of automotive parts. However, sometimes, we need to detach them for specific applications or renewals. So, we are using the spot weld drill bit systems for that removal. Here you can find detailed information about these drill bits that the panel welders are using.

What is Spot Weld Drill Bit?

Before understanding the spot weld drill bit, we need to understand what is the spot weld. Spot welding is a type of welding technique where we are overlapping the two panels, ap apply electric current between two bits by compressing to each other. So the electric current between the welding machine melts the panels in a localized way. This will provide very good welding operation.

We use spot welding applications in automotive projects in general. They are very common in automotive external thin sheet metal parts. And sometimes, we need need to remove these parts. But, welding is a permanent joining process. And they are not suitable for ripping off and attaching again. So we need a special tool that gives minimum damage to the sheet metal parts while removing the spot welds. These tools are the spot weld drill bit systems.

How to Use the Spot Weld Drill Bit?

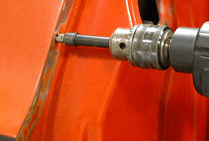

The use of them is very simple. You just need to attach these drill bits to an ordinary cordless drill chuck. And you need to apply it to the spot weld point by drilling it. It drills the first panel. But the spot weld will be detached without harming the second panel beneath the first one. There will be a hole on the first panel but it is very easy to repair in general.

General Prices of Spot Weld Drill Bit Applications

If you have a garage or workshop where you are dealing with cars and repair applications, you will probably need to spot-weld drill bit systems in your garage. Here, we can give some kinds of examples that you can use in your applications in general.

Spot Weld Cutter

- Double-sided 3/8″ high-quality high-speed steel material.

- For separating the spot welded panels without distortion.

- 5 extra blades.

This is the first example that you can consider to buy a spot well drill bit. This is a very useful and high-quality drill bit that you can use in applications.

- The carbon steel material provides very high quality. So, it will be very easy for you to deal with the spot weld detachment in your garage.

- You need to use it with corded electric drillers to get the best results.

- It comes with a 1/4″ standard arbor size. And the blade size is 3/8″ in diameter which is best for most spot weld drill bit applications.

- It can be used on the cast iron alloy steel, carbon steel, and on other materials without any problemç

- The package includes; a 3/8″ spot weld drill bit

- 2 pieces of pilot pins.

- 5 pieces of cutting blades.

- You can easily attach and detach the spot weld cutter from the drill bit without any problem.

- The double-sided design provides very good cutting operation.

- The centering tip provides more accurate words.

Spot Weld Cutter Kit

S&F STEAD & FAST Spot Weld Cutter Kit

- Different sizes of cutters.

- Angular cutter bits

- Different shank sizes with 1/4″ of cutting depth.

This is another good example that you can consider if you are looking for a spot weld drill bit set for your garage or workshop. So, it is very easy to attach and detach without any problem.

- The package includes 5/16”, 3/8″, 7/16”, 1/2″, 9/16”, 5/8, 3/4″ sizes of cutters. And also you will have an angular cutter.

- The high-speed steel provides very high-quality cutting operations without getting easily dull.

- The shank is threaded for a better assortment of different kinds of drill machines.

- You can obtain three times faster cutting operation with these high-speed steel drill bits if we compare them with the conventional systems.

- The sturdy case includes the; Cutter x 7,

- Arbor x 1,

- Pilot pin x 2,

- Center punch x 1,

- Small washer x 1,

- Large washer x 1,

- Hex wrench x 1;

General Applications that We Use These Systems

It is not just automotive, there are different kinds of applications that we are using the spot weld drill bit applications in general.

- HVAC: Most of the HVAC systems of the buildings have metal panels that cover the vital parts of these systems. The HVAC mechanics and technicians are using the spot weld drill bit to open the spot welds on these panels.

- Sheet Metal: The systems that have sheet metal covers have lots of spot weld joinings. So, you need to use the spot weld drill bits to detach the metal covers in general.

- Conduits: Piping systems have also lots of spot weld applications. If you are a mechanic dealing with piping and plumbing applications, you need to use the spot weld drill bits in general.

Last Words

Most people do not know about the spot weld drill bit applications. But they are very common systems in different areas. If you want to buy one of them, you can consider buying from Amazon.com and other sellers.

Leave your comments and questions below about this topic and leave your feedback!

Similar Contents;