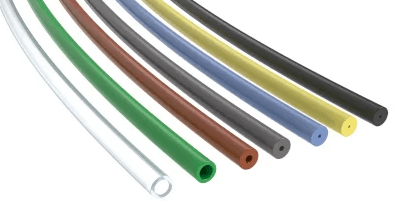

PEEK Tubing – Features and Uses

We are using tubing applications in different kinds of engineering systems in general. So, there are different kinds of materials that we are using for tubing applications. Around these materials, PEEK is a very common one. Here, we will take a closer look at the PEEK tubing applications.

What is PEEK Tubing?

The name may seem very different but, PEEK is a material Polyetheretherketone which is a very common polymer. People are using this PEEK name to make it much easier to pronounce. There are different kinds of features of the PEEK tubing applications in general.

- First of all, PEEK material is a biocompatible material. So, if you want to create an environmentally conscious system, you need to use this material for tubing applications.

- For liquid applications, the use of PEEK tubing applications become more and more common. Because they possess a very low chemical affinity to most fluids. And they show the same and better performance if we compare them with the metal tubings.

- Also, PEEK is a very flexible material. You can easily apply them for different applications. You can easily cut to different sizes easily.

- Has very good material properties for tubing applications in general.

- Also, the low level of friction provides very low turbulence levels for most of the fluids.

Material Properties of PEEK

Also, you need to know about the material properties of the PEEK applications. They are very common systems that we are using in different kinds of applications.

- Usable temperature: The temperature range of the PEEK tubes is -75 to 500 degrees Fahrenheit which makes it possible for most of the applications.

- Tensile strength: The tensile strength of this material is 14000 psi which is very good for tubing applications. And their impact strength is not good as expected.

- Rockwell hardness: Rockwell hardness of the PEEK material is R70 which is very hard for most applications.

Because of these properties of the PEEK material, they are used as replacement tubing applications with metals.

If we consider the other plastic materials, the PEEK is not compatible with low temperatures like the other ones. For example, PTFE is much better for low-temperature tubing applications.

Also, the tensile strength of this material is very high if we compare it with other plastic materials in general. Also, it is one of the highest with the Torlon PAI plastic.

As we stated above, the impact strength is not good. So, they are not compatible with outside applications. Also, they have moderate machinability which we do not deal with in the tubing applications.

Also if we compare with the other polymers, they are one of the most expensive materials.

Applications of PEEK Tubing Systems

There are different kinds of applications that we are using in the PEEK tubing systems.

- They are very good for medical applications such as neurovascular catheters and orthopedic implants. Because they have very good biocompatibility.

- In medical access applications, we use the PEEK tubing systems for medical applications.

- They are very good materials to replace metal and composite applications.

- We use them in spacers and bushing applications.

- Also, we are using them for MRI-compatible metal replacement applications.

Conclusion

As you see above, PEEK tubing applications are very special systems that we are using in medical applications in general.

If you have additional comments and questions about the PEEK tubing, please leave them below.

And you can find other insightful posts about the different systems on fmechanic.com!