Clamp Lock Mechanisms – Different Types and Uses

Clamping mechanisms are very important in manufacturing applications. They are very useful in different kinds of applications in general. We use clamp lock systems in manufacturing and woodworking applications. Here, we will take a closer look at the clamp lock systems.

What is Clamp Lock?

A clamp lock is a mechanism for clamping and fixing the workpieces in different kinds of applications. For example, we use them to lock the workpieces on benches to drill with drill presses. So, they are very important systems in workshops. Here, we will check the different types of them.

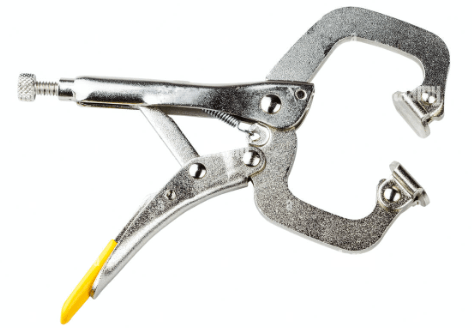

Plier Clamp Lock Systems

They are one of the most common systems that we are using in clamping applications. There is a jaw system that we can adjust the reach and the openness to clamp the workpieces. And we can carry the workpieces with these clamps.

These clamps are generally useful for combining the different parts in welding operations. They hold fixed the workpieces and we can apply the welding operation.

- Bar-Type Clamps: This is a configuration of the plier clamp lock systems. There is an upright bar that the upper jaw moves along this jaw. Because of this movement, we can reach even 10″ of clearance. So, attaching much thicker workpieces is possible.

Portable Bench-Top Clamp Lock Systems

In these systems, there is a flat plate and a mechanism to that we can attach the workpieces on them. We squeeze the workpiece between the clamp and the flat top. They are very useful in small woodworking applications.

Bench-Mount Clamp Systems

Also, they are the systems where we can clamp the materials directly on benches. You can attach these clamps to the bench with screws and the clamping jaw directly fixes the workpieces to the bench. For metal and wood machining operations, they are very useful.

Sheet Clamp Lock Systems

The jaw design is very useful for sheet clamp lock systems. The jaws provide a very good attachment of the sheet metal parts that you can easily apply the riveting and welding applications. Also, they are very useful for painting applications in general.

Important Parameters

Also, these are the important points that you need to consider while you are selecting clamp lock systems in general.

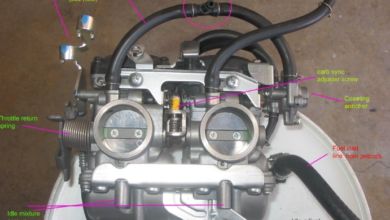

- Jaw Type: As you see in the different models, the type of the jaw directly defines the type of workpiece that you can directly attach to the system. Some jaws are pivoting and some the fixed according to the type of work at hand.

- Jaw Material: Also it is a very important ğoint to consider. If you are clamping sensitive workpieces, you need to consider the rubber clamp material in general. But also for better fixing, metal jaw material is very common.

- Holding Capacity: This is also a very important point that you need to consider. What is the maximum holding capacity that you need for your applications? The holding capacities of different clamp lock applications range from 300 lbs to 1000lbs. You need to have a strict range.

- Jaw Opening: Jaw opening directly defines the maximum workpiece thickness that you can attach to the clamp lock.

- Reach: The reach defines the maximum depth that you can attach the workpiece in general.

Last Words

After you defined these parameters and types, you will be able to select the best application for yourself.

If you have additional comments and questions about this topic, please leave them below.

Also, you can find other useful articles and posts about the different mechanical systems on fmechanic.com!