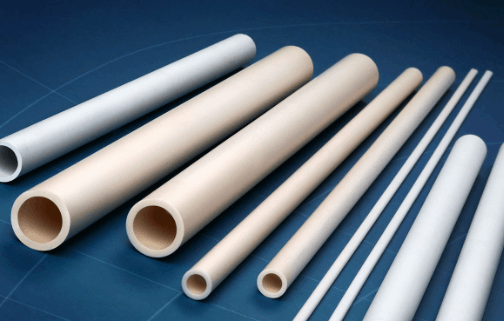

Ceramic Tube – Applications and Types

In different places and applicaitons of industry, we use ceramic tube applications in general. Here you can find detailed information about ceramic tube applications and their general uses.

What is Ceramic Tube?

As you understand from its name, ceramic tube systems are tubes that are made from different kinds of ceramic materials. There are different kinds of properties that we generally use in different areas;

- Casting supports: Ceramic tube applications have very good thermal properties that they are not deteriorating in very high temperatures. And they do not lose their mechanical properties at these high temperatures. So, in the casting applications in which high temperatures are common, we use them as structural elements.

- Surgical devices: Because of their crystal structures, we can obtain very sharp and safe knives from tubes. So, their uses are very common in surgical applications in general.

- Sharpeners: Also, their uses are very common in knife sharpening applications. They are very common in different kinds of applications that we use.

- Thermal insulations: As we stated that the thermal properties of ceramic tube applications are very useful in general. We use them for thermal equipment and applications in general. So, we use them as thermal insulators for electrical equipment.

- Resistors: In high power and high electrical resistors, we use these applicaitons in general. Because they have very good resistive properties and very good thermal properties that can withstand high-resistance applications.

- Thermocouples: Also they are very useful for thermocouple applicaitons. In some high-temperature applications, you can use the thermocouple systems that are installed inside these systems in general.

As you see above, the uses of ceramic tube applications are very common in general.

Types of Ceramic Tube Systems

There are different materials of ceramic tubes that we use in different kinds of applications.

- Aluminum oxide tubes: Aluminum oxide tubes are also very common in different kinds of applications. They are very useful for different kinds of hşgh temperature applications. They have stability up to 1800 degrees Celsius which is very useful for high-temperature applications. And they provide very good vacuum and thermal shock properties.

- Silicon carbide tubes: Silicon carbide tubes have higher temperature resistance than aluminum oxide ones. They can save their properties up to 2600 degrees Celsius which is very high if we compare it with the other systems. Also, the hardness values of these applications are much higher. They are generally manufactured with the sintering method. And dimensional properties are much better than the normal tube applications.

Conclusion

These are the general properties of ceramic tube applicaitons. There are different manufacturers are available that you can easily find through their catalogs. If you have additional comments and questions about them, please leave them below.

And also, you can find other kinds of useful articles and posts about industrial systems on fmechanic.com!