Hardness is a very important feature of a material that we need to measure to assess this feature. We are using this feature to compare it with other kinds of materials. While measuring the hardness, we are using Brinell hardness tester in general. They are very calibrated machines that they are giving direct insight to measure them. Here, we will explain different kinds of Brinell hardness tester in general.

What is Brinell Hardness Tester?

Brinell hardness tester is the machine that are testing the hardness of the materials in the Brinell scale. With these testers, we know the general hardness of the materials.

Why Hardness is Important?

In the commercial transfers of the engineering materials, we are using the hardness feature of the material to show the general wear resistance. And there are different scales are used like the Brinell hardness test. And according to these tests, you can define the average Brinell hardness. Also, the customers can compare these values between the materials that they are looking for.

So, if you are dealing with a commercial selling of the materials, you need to have a Brinell hardness tester.

Before understanding the types of Brinell hardness tester, we need to somewhat learn about this test in general.

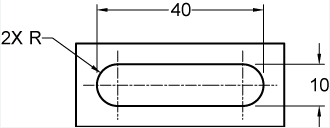

The Brinell hardness test is a there are different sizes of indenters are applied to the local sections of materials to see how much indent takes place. These indenters are all spherical. And various sizes of spheres are applied in various force effects in general.

While applying the Brinell hardness tests, this indenter is applied with a specific force. After the application, the depth of the indent is measured by the operator or machine. So, accuracy is very important in this case. If the size of the indent is very small, you need to measure the size of the indent with very good accuracy. So, different kinds of devices are generally used in the Brinell hardness tests.

Types of Brinell Hardness Tester

There are different types of these testers that are making the Brinell tests with different accuracies and different methods. According to the accuracy that you need, you can select one of them for your company.

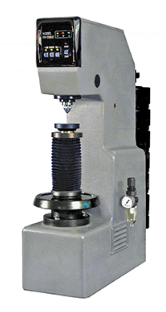

Automatic Brinell Hardness Tester

These Brinell hardness tester machines are the most accurate machines that you can apply these tests to different kinds of materials. You can attach different kinds of indenters and there is a pneumatic system that applies the load in specific portions. You can adjust the standard load applications with the pneumatic system.

A pneumatic system provides a much more better and accurate application of load in an impact-free way. It applies the load gradually without harming the material on the test.

Advantages;

- If you need high-accuracy Brinell hardness tester, you can consider these machines.

- You can easily adjust the level of the indenter and adjust the indenter as touching the surface of the material. And adjust the machine to apply the forces.

Disadvantages;

- They are generally the most expensive Brinell hardness tester around the other ones.

- They can take up much more space in your laboratory if we compare them with the other devices.

Manual Brinell Hardness Tester

Like the automatic testers, there are also manual ones available in the market. You can apply the Brinell hardness tests with the manual arm. By rotating this arm you can easily apply the required force on the specimen.

Also with the lock mechanism, you can easily lock the material specimen on the system. So, it will be very easy for you to adjust the special according to the tests. From the analog clock on that tester, you can read the general test result you are having in general.

It can be used nearly in all laboratories. According to the ASTM E-110 standards, these devices are usable in lots of laboratories in general.

Advantages;

- The most important advantage of these devices is the price. Manual systems are much cheaper than automatic and electronic systems in general.

- Easy to operate. Manual Brinell hardness tester is much easier to test with different kinds of materials. You just need to place the material specimen and apply the force gradually with the arm.

Disadvantages;

- Manual systems are generally open to more external effects. You may have calibration problems with the manual Brinell hardness tester in general.

- The accuracy of the manual systems can be lower than the automatic and electronic systems.

Hammer and Pin Type Brinell Hardness Tester

This is the most basic type of them. In these systems, there is a shear pin and hammer that you can make an impact on Brinell tests on the material specimens. Once you adjust the indenter and attach this indenter to the pin, and once you apply the impact force, the shear pin breaks and you applied the required amount of force that the test needs.

And these devices generally come with calibrated shear pins that you can use in your laboratories in general.

Advantages;

- Most easy-to-apply Brinell hardness tester.

- The lowest price is around the other ones.

- Very compact systems that will not take up lots of space in your laboratory.

Disadvantages;

- Open to operator assessment.

- You are testing the specimen by applying impacts. So, impacts can be problematic in the Brinell tests.

- Every time, you need calibrated shear pins for different tests. This is the constant expense of running.

Last Words

Building a laboratory is very important for the quality assessment and manufacturing of the materials according to the standards. You may build a laboratory that includes devices and systems and you are independently making tests.

And also, you are building a laboratory in a factory to test the manufactured products. And if you need to apply the Brinell hardness tests, these are the general types of tester. According to the advantages and disadvantages, you can select one of them according to your needs. Also, you can contact us in the comments or the e-mail to ask questions about these systems.