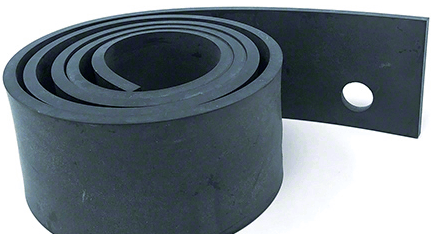

Gum Rubber – Explanation, Features and Applications

Polymer materials became a very important part of human civilization after the 19th century. And there is a wide variety of polymer materials that we are using in different applications. One of these materials is gum rubber. Here you can find detailed information about this material that is used in various kinds of applications.

What is Gum Rubber?

Gum rubber is the term people are using for natural rubber. They are natural because they are manufactured naturally. There is a special tree that produces this material just like pine resin. But it possesses very important features that are useful for people.

Firstly the Europeans made them of conventional material. They applied additional curing operations to this latex liquid that comes from these trees to obtain the natural rubber or gum rubber.

Features of Gum Rubber

Gum rubber has various kinds of features that we are using in human civilization. They become very common because of these features.

Flexible

In general, rubbers are highly flexible. Our flexing ranges can be up to 10 times their original lengths. And they are not elastically deformed of the flexing. Because of these reasons they are finding different kinds of applications that we need flexible materials.

The flexibility comes from the molecular structures of these applications. They have very long organic molecular chains making them possible to extend. These molecular chains are linked to each other and give the possibility for stretching.

Also, this flexible nature gives a very good tear resistance to gum rubber material. So in coating applications, they are very common.

Resistant to Chemical Attacks and Acids

Because of their complex molecular structure, acids generally can not dissolve these materials. Because of this reason gum rubber materials are very resistant to chemical attacks and other applications.

So in the acid containers and systems that we are using the corrosive environments, we are using gum rubber material in general.

Good Shock Absorber

Gum rubbers have very good shock absorbing capacity. Their elastic structure and complex molecular links provide very good damping ratios to different vibrational effects. So the use of gum rubber material in shock absorber applications in engineering is very common.

Biodegradable

In today’s world, it is a very important characteristic that we are expecting from materials. The gum rubber material is a natural material that we are having from natural sources. So, they are completely biodegradable materials.

There are lots of scientific surveys and applications in the biodegradable polymers being developed. So, in terms of the environmental aspects, it is a very common and very important material that we can use in biodegradable and environmental-friendly systems.

Applications of Gum Rubber

Because of these distinct properties and features of these materials, there are different kinds of applications that we are using for engineering purposes.

Floor Covering

The flexible, tear-resistant, and soft structure of gum rubber makes it very ideal material for floor covering applications. There are different kinds of services that are making floor covering in houses.

Sealing and Gasket Manufacturing

Seals and gaskets are very important parts of the different kinds of machinery applications. Without sealing, we can not have pump systems, or engine systems to give the real power for the different applications.

Gum rubber has a very good characteristic of sealing. So, we are manufacturing different kinds of gaskets and seals for machinery from this material.

Gum Rubber Hose

Because of their flexibility and high tearing resistance, the use of gum rubbers in the garden hose and other plumbing applications is very common. They are not chemically affected by water. So, they are very convenient materials in plumbing and ducting applications.

Machinery Belt Systems

Gum rubber material has very high frictional characteristics. We need that friction in the power transmission application in the machinery. And belt mechanisms need that friction between the belt pulleys and the belts. So, we are using vulcanized applications in the machinery belt systems. They are very durable and high in strength for load carrying, and they provide very good frictional characteristics in general.

Safety Gloves

You may see that laboratory technicians are using rubber safety gloves while they are dealing with acids and chemicals. The most common material that we are using in safety gloves is gum rubber. They are very common in safety applications.

They are flexible to take the shape of a hand and they are resistant to chemical attacks that protect the hands of the laboratory operators.

Cloths

Also, the use of polymers is very common in daily clothing. Because they provide very good elasticity to these clothes. It is a natural material that is safe for human use. And their use for daily cloths is very common in generalş.

Adhesive Applications

If we vulcanize the gum rubber and expose it to UV light, they become harder. We call this phenomenon cross-linking. Because of this property, we are using these applications in adhesive manufacturing.

Vibration Control and Shock Absorbing Applications

Vibration is a very common phenomenon in design engineering. There are different kinds of systems such as precision manufacturing machines that we need to protect from vibration. So, for vibration isolation applications, the use of gum rubber applications is very common.

Flotation Equipment

We are using the buoyancy of water in engineering systems such as float valves. It is a very good material that can float on water. So if we need a material that needs to float on water, gum rubber is a very common material in that sense.

Vulcanization of Gum Rubber

After we obtain them from natural sources, we apply some processes to make them stronger and harder. We call this process vulcanization. In vuşcatization, we add sulfur to the natural ruıbber by applying heat. This forms extra crosslinking structures between the complex molecules. So, we gain strength by expensing from the elasticity.

For example, in tire manufacturing, vulcanized rubber material is very important. They have very high tear resistance and very good frictional capabilities that we need in tire applications.

Last Words on Gum Rubber

These are the general important points that we can state about gum rubber applications. They are very special materials to different extents and we are using them in different applications.

If you have additional questions or comments about this material, leave them below. You can also find other informative articles about engineering materials on fmechanic.com!