Drum Brake Diagram – With Clear Explanations

Here we will explain the working principle of the drum brake and also explain the old important parts of the drum brake diagram. So at the end of this content, you will be able to learn all the systems that you need to learn.

What’s the Drum Brake?

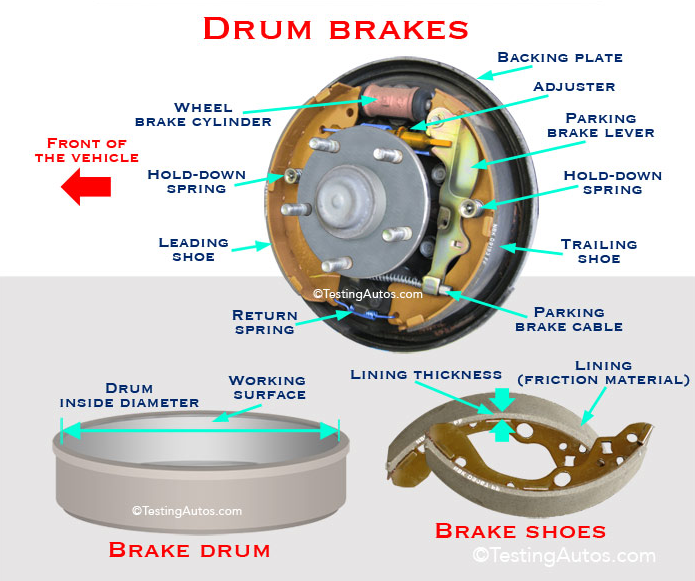

If you take a look at the structure of the drum brake, there’s a rotating drum that is attached to the axle of the car. So with this attachment, once the wheel of the car rotates, the drum rotates. Also, there are brake shoes which are leading shoes, and trail shoes are connected to the drum brake system.

Wants the driver to press on the brake pedal, and the shoes can contact the breakdown that slows down the vehicle. The friction between the brake shoes and the brake drum creates heat which slows down the vehicle. This is the most general working principle of the drum brakes.

Drum Brake Diagram Explanation

Here you can see a clear explanation of the different kinds of parts inside the drum brake systems. We can explain all of these parts.

- Wheel Brake Cylinder: Two-Wheel Brake Cylinder is the system that the hydraulic fluid that comes to the brake system. Once the hydraulic fluid comes to the brake cylinder, the two pistons inside the cylinder are pushing the brake shoes to the rotating breakdown which creates the braking effect. So it’s a very important part that receives the high-pressure hydraulic fluid that comes from the master cylinder. And there are different kinds of ceiling parts inside that will break the cylinder.

- Backing Plate: The Baking Plate is the chest iron plate that includes all the systems and parts of the drum brake system. So this is an external cover that prevents any dirt or another kind of materials that come from the outside. Also, there are different kinds of holes and places where the other drum brake systems and parts are attached to.

- Hold Down Spring: This is a spring system that is attached to the brake shoes that holds the brake shoes in the correct position. Once you apply the brake pedal, the brake shoes are pressed against the brake drum. So once you depress the brake pedal to hold down the springs take the gray shoes in the correct position again. Also, they make sure that the position of brake shoes is in the correct position according to the baking plate. So there are two drinks that hold these two different shoes inside the drum brake system.

- Parking Brake Lever: This is a lever that is connected to the handbrake of your car. Once you pull the handbrake off your car, the parking brake applies the brake shoes to the brake drum system. So it’s a letter that is connected to Mechanical cables that are corn also connected to the handbrake. Once you pull the handbrake deliver activates and pushes the brake shoes on the brake drum to make sure that brakes are applied.

- Return Spring: Return Spring is the spring that makes sure that the brake shoes are came to the correct position after the brake pedal is released. Once you release the brake pedal, the hydraulic fluid inside the real price cylinder is also released. But it does not make sure that the broken shoes get the old position. But the return Sprint mechanism takes the brake shoes to the primary place with the whole town spring. The difference between the whole town spring and return spring is, to hold down spring position date shoes at a correct distance between the backing plate. But return spring positions or reposition the brake shoes to the primary position after the breaking.

So as you understand that these are the general parts inside the drum brake system and these are the general working structure of the drum brakes on your car.

Also very important to understand the friction between the brake drum and the brake shoes. As you know that the external surface of the brake shoes are came into contact with the internal surface of the break drum. So changing the brake shoes is similar to the change of the brake pads in the caliper brake systems.

What Is the Lining on Brake Shoes?

As you see, there is a lining thickness and lining on the brake shoes. As you understand, this lining comes into contact with the working surface of the brake drum. When the brake drum rotates with the rotating axle, once you press on the brake pedal, the brake shoes make radial movements to the working surface of the brake drum, and the braking effect takes place with this working structure.

The lining’s thickness gives the remaining life to the brake shoes. When you change the brake shoes with new ones, the lining thickness is highest. With the passing of time, the lining thickness will decrease over time. After a specific thickness, you need to change the brake shoes with new applications.

Conclusion on Drum Brake Diagram

In here, it’s right to explain the old parts and the working structure of the drum brake by using a drum brake diagram. So, their working principle is very simple to understand, and you know all the parts and their duties inside the drum brake system. If you have additional comments and questions about this topic, you can leave them below.

Check similar topics about the brake systems of vehicles;

Brake Line Replacement Cost – What are the General Costs?

How to Get Air Out of Brake Lines Without Bleeding? – Without Confusion!